A method for producing leather release type base paper

A production method and release technology, applied in papermaking, paper coating, papermaking and other directions, can solve the problems of high cost, dependence on imports of leather release paper, and restricting the rapid development of artificial leather.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

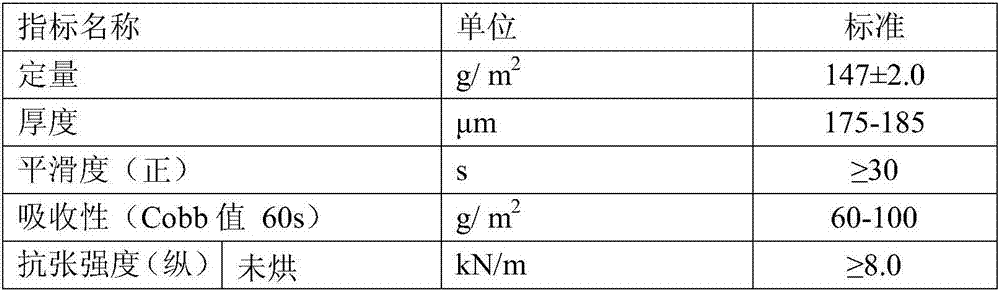

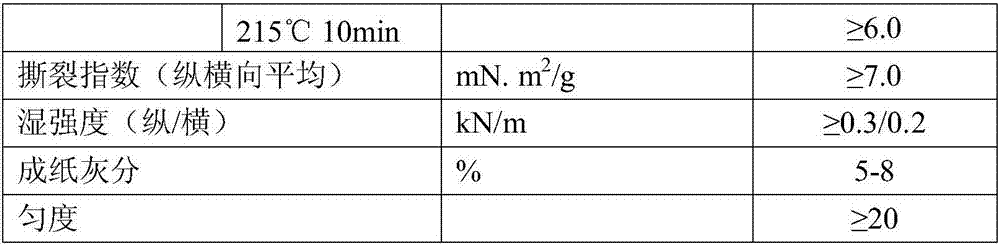

[0018] Example 1: 147g / m 2 Leather release base paper, making speed 160m / min

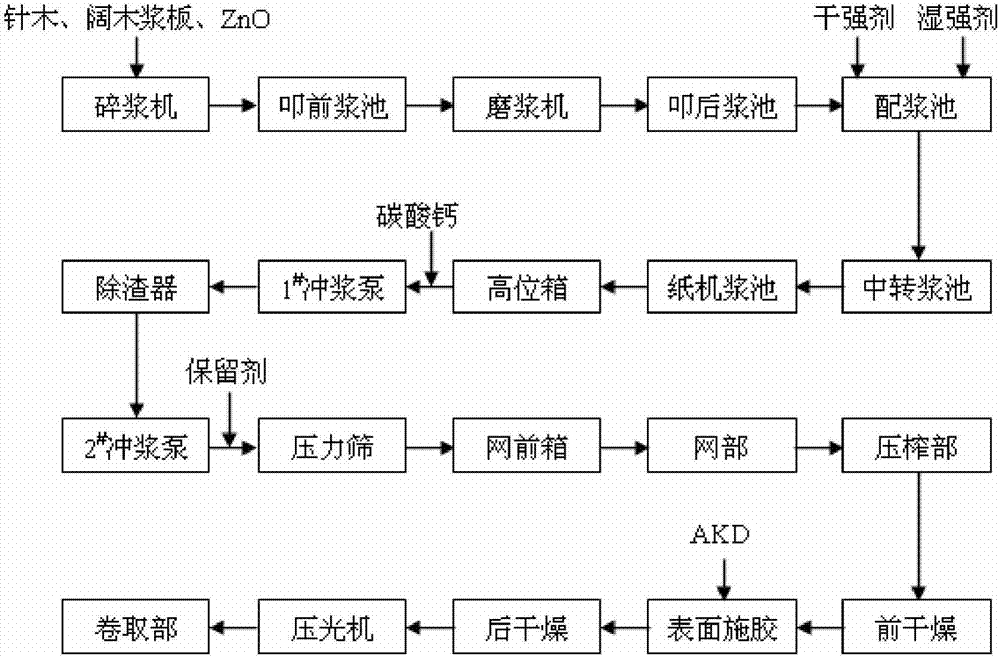

[0019] The production method of the leather release base paper is produced by an ordinary fourdrinier multi-cylinder paper machine. The production process is beating, pulping, sizing, papermaking, drying, surface sizing, calendering and rewinding to make finished paper. Leather release base paper uses bleached kraft needles and hardwood pulp as the main raw materials, chemical additives fillers (ZnO and calcium carbonate), dry strength agent, wet strength agent, retention agent and AKD (alkyl ketene dimer) as auxiliary raw materials. The specific process is as follows:

[0020] (1) Sizing ratio and beating: bleached kraft softwood pulp is equipped with 20%, bleached kraft hardwood pulp 80%; softwood pulp beating concentration 3.1%, freeness 360ml; hardwood pulp beating concentration 4.6%, Freeness 440ml

[0021] (2) Auxiliary raw materials:

[0022] The dosage of filler ZnO is 2.1% / dry pulp; th...

Embodiment 2

[0030] Example 2: 147g / m 2 Leather release base paper, machine speed 180m / min

[0031] The production method of the leather release base paper is produced by an ordinary fourdrinier multi-cylinder paper machine. The production process is beating, pulping, sizing, papermaking, drying, surface sizing, calendering and rewinding to make finished paper. Leather release base paper uses bleached kraft needles and hardwood pulp as the main raw materials, chemical additives fillers (ZnO and calcium carbonate), dry strength agent, wet strength agent, retention agent and AKD (alkyl ketene dimer) as auxiliary raw materials. The specific process is as follows:

[0032] (1) Sizing ratio and beating: bleached kraft softwood pulp is equipped with 30%, bleached kraft hardwood pulp 70%; softwood pulp beating concentration 3.8%, freeness 380ml; hardwood pulp beating concentration 4.9%, Freeness 470ml

[0033] (2) Auxiliary raw materials:

[0034] The dosage of filler ZnO is 2.8% / dry pulp; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com