Packaging adhesive for infrared LED chip, preparation method and application thereof

A technology of LED chips and encapsulation glue, applied in the field of material chemistry, can solve the problems of fast decay rate, poor moisture and heat resistance, high cost of silica gel, and achieve the effect of high reliability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] An encapsulant for infrared LED chips, consisting of component A and component B,

[0053] The A component is prepared from the following raw materials:

[0054] epoxy resin

[0055] Bisphenol A epoxy resin 95g

[0056] Active diluent

[0057] Benzyl glycidyl ether 4g

[0058] Auxiliary

[0059] Defoamer (silicone modified polymer defoamer, model: BYK-SP) 0.5g

[0060] Leveling agent (silicon polyether copolymer, model: SLE-7350) 0.5g

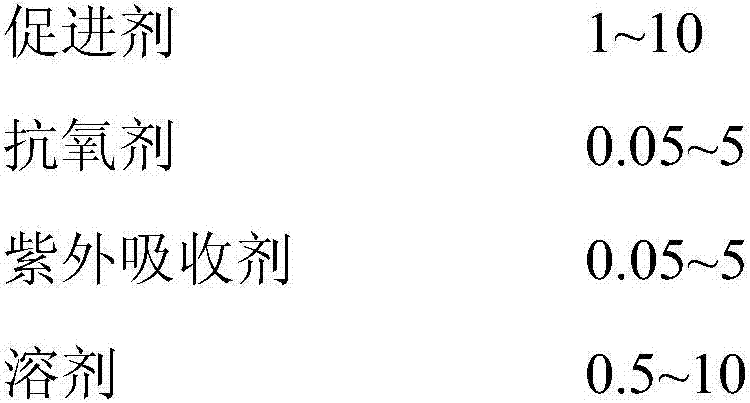

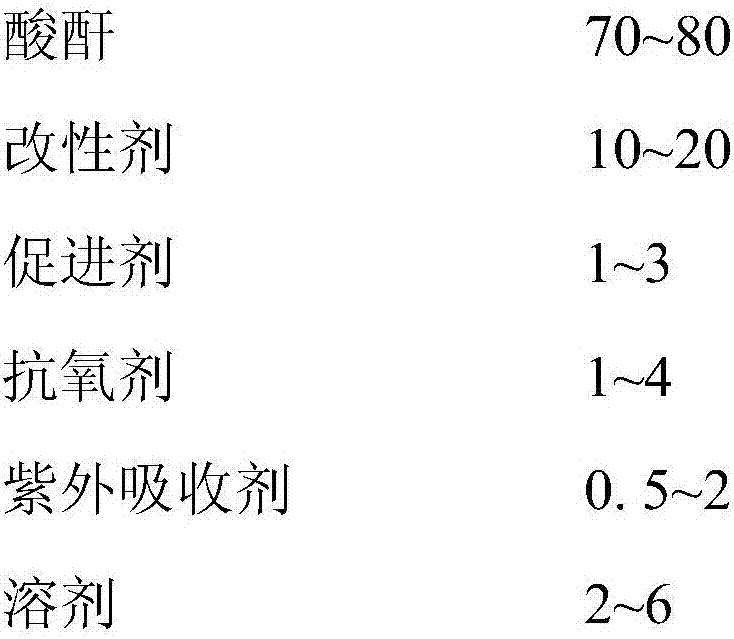

[0061] The B component is mainly prepared from the following raw materials:

[0062] Anhydride

[0063] Methyl hexahydrophthalic anhydride 30g

[0064] Hexahydrophthalic anhydride 40g

[0065] Methyl Nadic Anhydride 5g

[0066] modifier

[0067] Silicone resin, model: SC-B22 15g

[0068] Accelerator

[0069] Tetrabutylammonium bromide 2g

[0070] antioxidant

[0071] Triphenyl phosphite 2g

[0072] UV absorber

[0073] 2-(2′-Hydroxy-5′-methylphenyl)benzotriazole 1g

[0074] solvent

[0075] Glycerol 5g

[0076] The mass...

Embodiment 2

[0082] An encapsulant for infrared LED chips, consisting of component A and component B,

[0083] The A component is prepared from the following raw materials:

[0084] epoxy resin

[0085] Bisphenol A Glycidyl Ether 90g

[0086] Active diluent

[0087] C12~14 Alkyl Glycidyl Ether 10g

[0088] Auxiliary

[0089] Defoamer (silicone modified polymer defoamer, model: BYK-072) 0.5g

[0090] Leveling agent (silicon polyether copolymer, model: SLE-7350) 0.5g

[0091] The B component is mainly prepared from the following raw materials:

[0092] Anhydride

[0093] Methyl hexahydrophthalic anhydride 30g

[0094] Hexahydrophthalic anhydride 45g

[0095] Pyromellitic anhydride 5.5g

[0096] modifier

[0097] Silicone resin, model: SC-B22 10g

[0098] Accelerator

[0099] Triphenylbutylphosphine bromide 1.5g

[0100] antioxidant

[0101] Trioctyl phosphite 2g

[0102] UV absorber

[0103] 2,4-Dihydroxybenzophenone 1g

[0104] solvent

[0105] Cyclohexanol 5g

[0106] T...

Embodiment 3

[0112] An encapsulant for infrared LED chips, consisting of component A and component B,

[0113] The A component is prepared from the following raw materials:

[0114] epoxy resin

[0115] Bisphenol F type glycidyl ether 88g

[0116] 3,4-Epoxycyclohexylcarboxylate 7g

[0117] Active diluent

[0118] Propylene oxide phenyl glycidyl ether 4g

[0119] Auxiliary

[0120] Defoamer (silicone modified polymer defoamer, model: BYK-072) 0.5g

[0121] Leveling agent (silicon polyether copolymer, model: SLE-7350) 0.5g

[0122] The B component is mainly prepared from the following raw materials:

[0123] Anhydride

[0124] Methylhexahydrophthalic anhydride 30.5g

[0125] Hexahydrophthalic anhydride 45g

[0126] modifier

[0127] Silicone resin, model: SC-B22 15g

[0128] Accelerator

[0129] Triphenylmethylphosphine bromide 1.5g

[0130] antioxidant

[0131] Trioctyl phosphite 3g

[0132] UV absorber

[0133] 2,4-Dihydroxybenzophenone 1g

[0134] solvent

[0135] Methy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com