Water purifying and quality guaranteeing system

A water purification and purification unit technology, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of loss of sterilization and disinfection functions, pollution of water tanks and water passing parts, and inability to wash away bacteria, etc., to achieve Eliminate the growth and reproduction of bacteria, low cost of use and maintenance, and not easy to be aged and polluted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

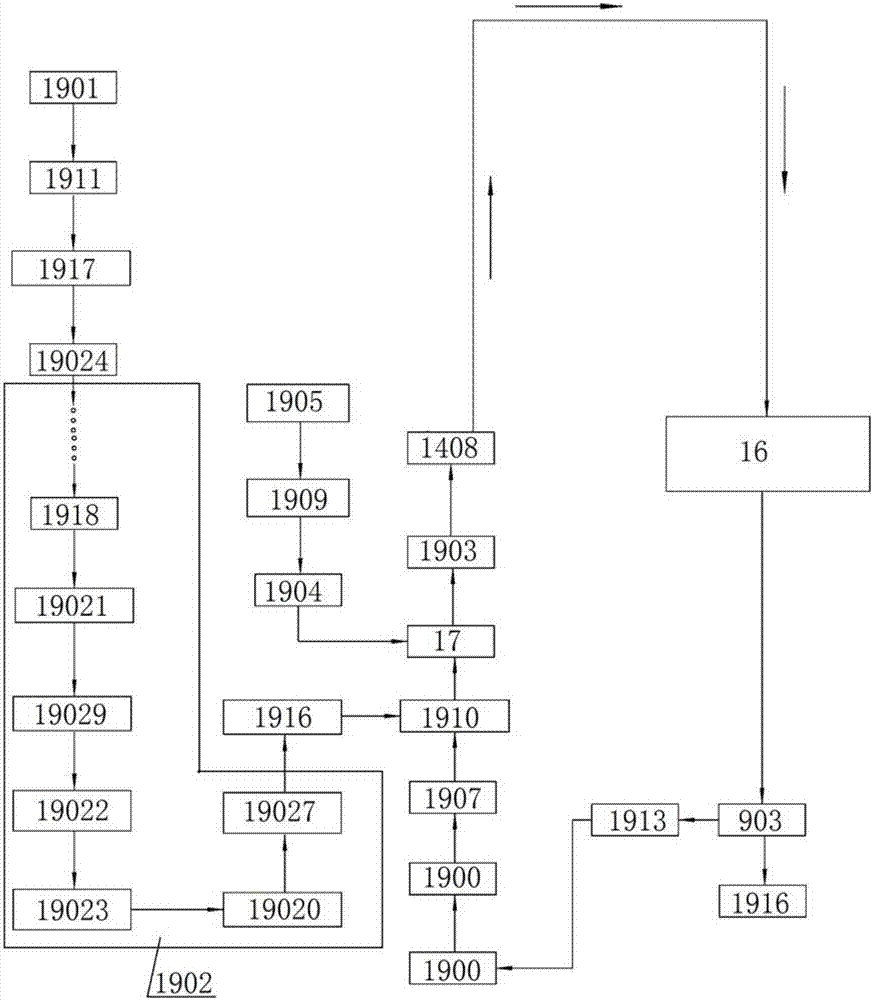

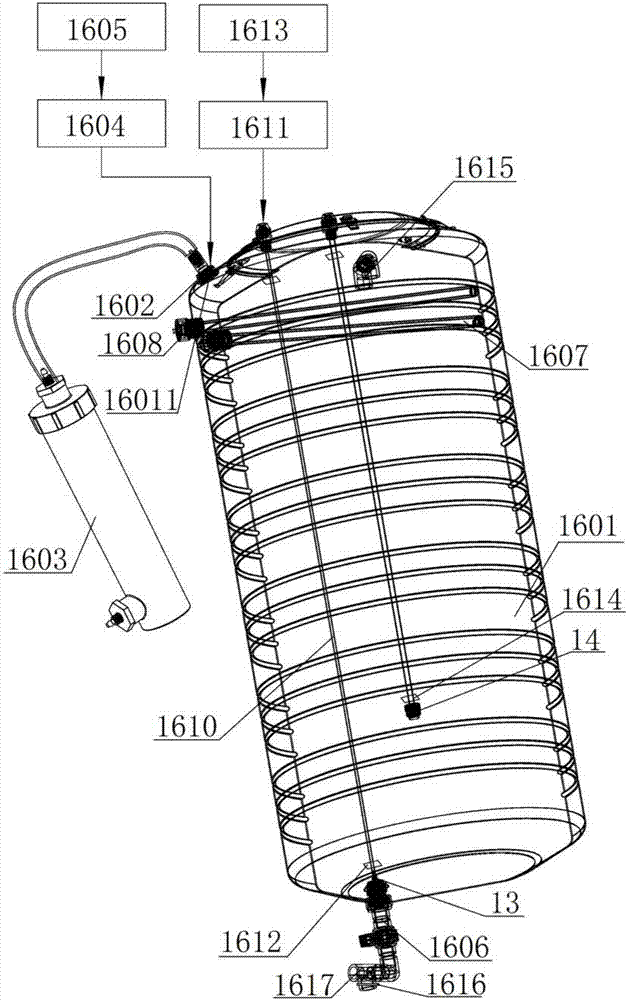

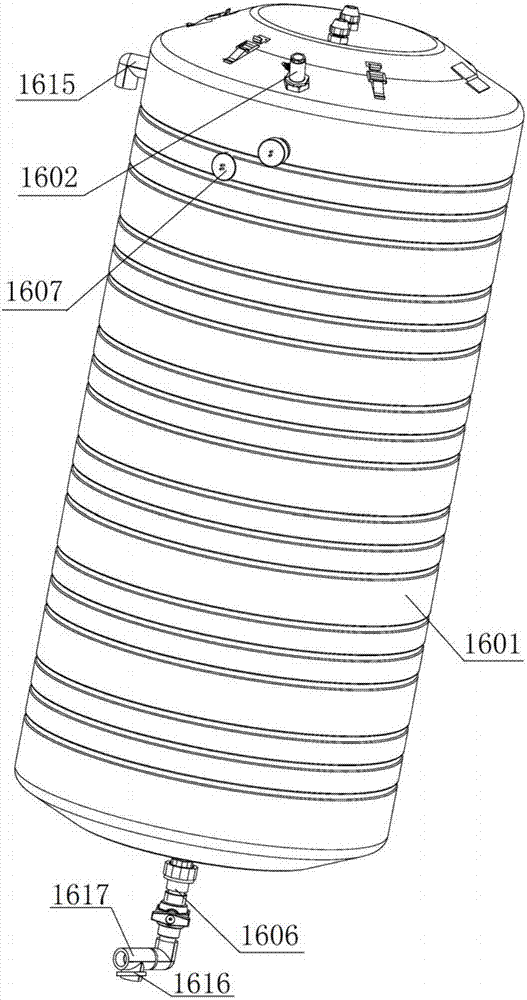

[0069] like Figure 1 to Figure 27As shown, the water purification and quality assurance system includes a raw water supply unit 1901, a raw water purification unit 1902, a water-air mixer 17, a booster pump 1903, a water purification tower 16, a first ozone generator 1904 and an air pump 1905, and the water purification tower 16 Including the water purification tower body 1601, the top of the water purification tower body 1601 is provided with a siphon port 16011, the raw water supply unit 1901 communicates with the water inlet end of the water-air mixer 17 through the raw water purification unit 1902, and the air pump 1905 is connected to the first ozone generator The inlet end of 1904 is connected, and the output end of the first ozone generator 1904 is connected with the inlet end of water-gas mixer 17, and the water outlet end of water-gas mixer 17 is connected with the inlet of water purification tower 16 by booster pump 1903. The water port is connected, and also includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com