Lubricating equipment for chain teeth

A technology for lubricating equipment and sprockets, applied in mechanical equipment, belts/chains/gears, cleaning methods using liquids, etc., can solve the problems of difficult cleaning, reduced lubricating ability, wear of parts, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further detailed explanation through specific implementation mode below:

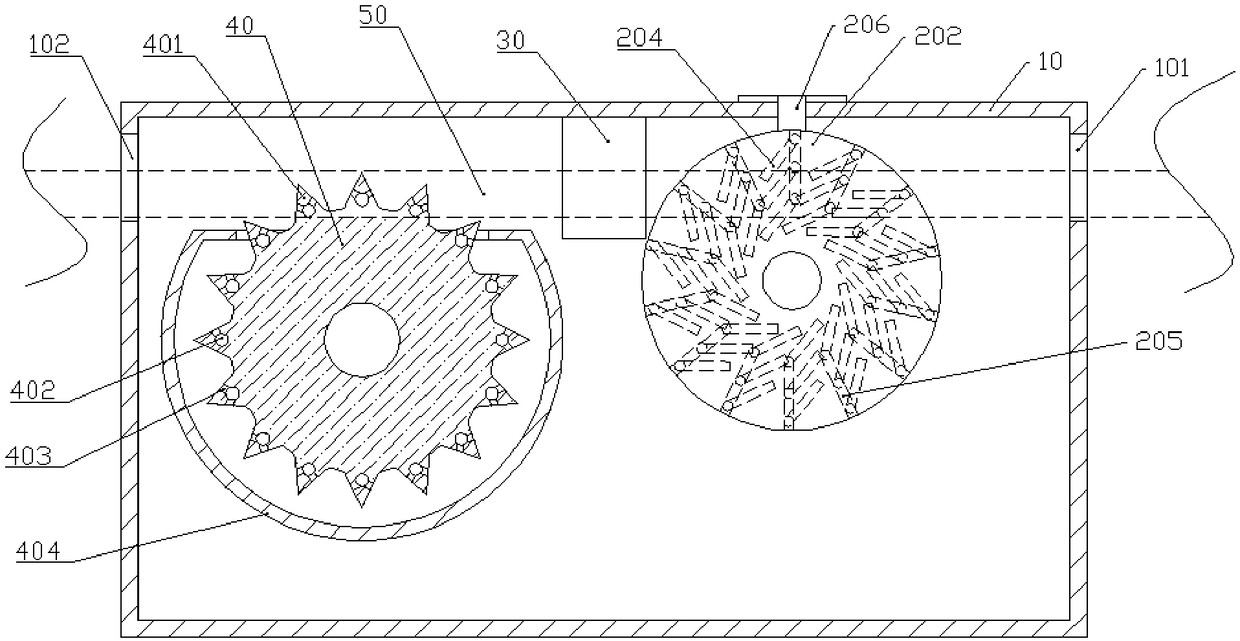

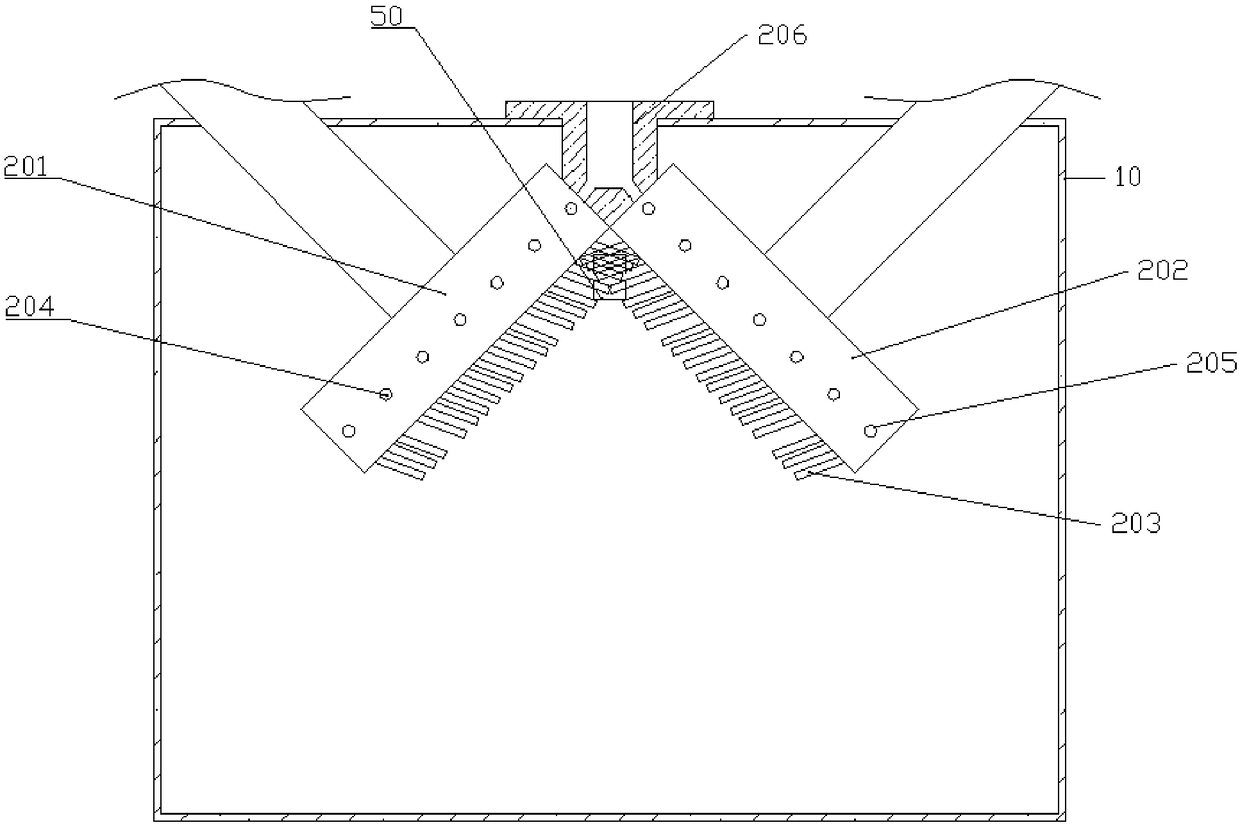

[0018] The reference signs in the accompanying drawings of the description include: casing 10, inlet 101, outlet 102, first cleaning tray 201, second cleaning tray 202, cleaning brush 203, first water inlet chamber 204, second water inlet chamber 205, Water inlet pipe 206, sponge 30, chain disc 40, sprocket 401, oil inlet pipe 402, oil outlet hole 403, inner shell 404, chain 50.

[0019] The embodiment is basically as attached figure 1 And attached figure 2 Shown: the lubricating equipment that is used for sprocket 401, comprises casing 10, drying unit and the cleaning mechanism and transmission mechanism that are arranged in casing 10, is provided with inlet 101 on the right side of casing 10, and the left side of casing 10 An outlet 102 is provided on the side. The cleaning mechanism is located on the right side of the cabinet 10, the transmission mechanism is located on the left side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com