Blockage preventer for grouting sleeves of prefabricated parts

A technology for grouting sleeves and prefabricated components, which is applied to building components, structural elements, building reinforcements, etc., can solve problems such as clogging of grouting sleeves, and achieve the effects of preventing leakage of grouting from clogging the sleeves, avoiding post-cleaning, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

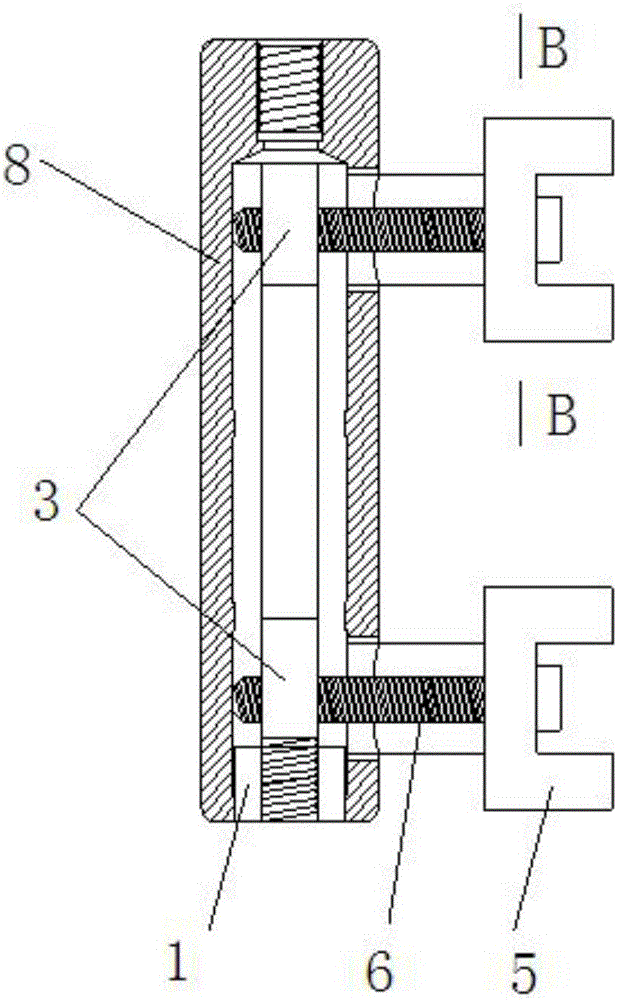

[0018] Such as figure 1 The anti-clogging device of the grouting sleeve of the prefabricated component is related to the grouting sleeve 8. The grouting sleeve 8 is composed of a grouting section, a grouting hole and a grouting hole. The grouting section is sealed with a grouting section sealing assembly, a grouting hole and a grouting hole A group of hole sealing components are respectively sealed inside.

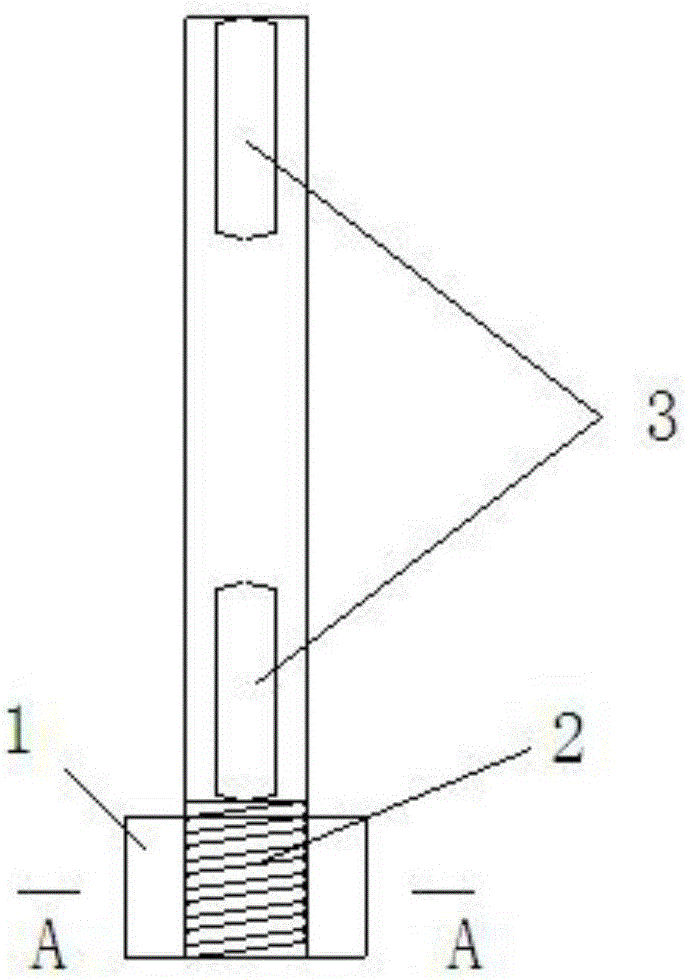

[0019] The plugging component of the grouting section includes a rubber base 1 and a rod 2, see image 3 , the lower part of the rod 2 is a threaded rod, the middle part of the base is embedded with a nut matching the threaded rod, the rod 2 is threaded with the base 1, the rod 2 is located in the grouting section, and the base 1 is embedded in the opening of the grouting section, The lower part of the base is provided with steel bar 4, which is convenient for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com