A quality control system for bubbles in autoclaved aerated concrete

An autoclaved gas filling and control system technology, applied in the direction of manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems affecting the strength and appearance quality of aerated brick buildings, product thermal conductivity, compressive strength and sound insulation drop Unsatisfactory noise effect and other problems, to achieve the effect of improving appearance quality, overall quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

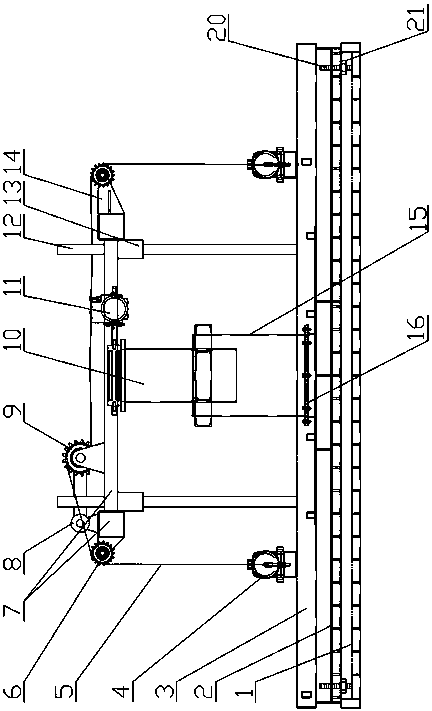

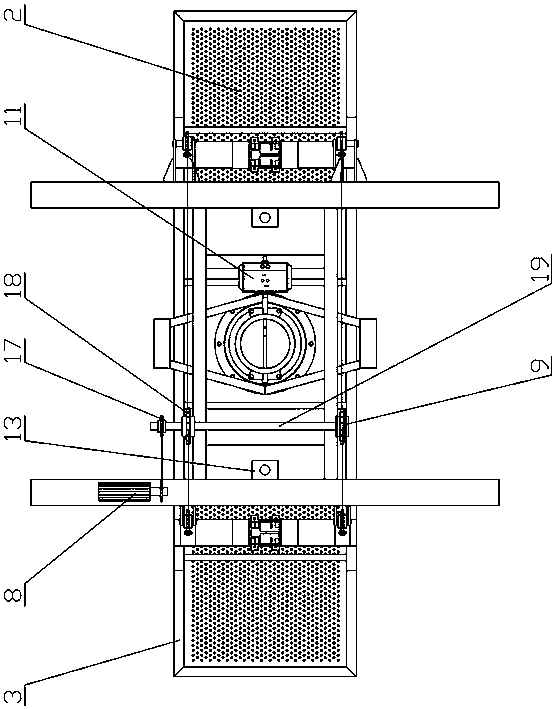

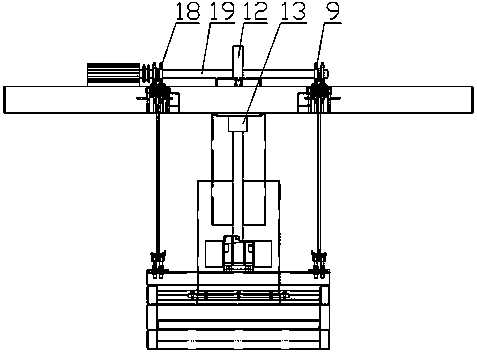

[0023] see Figure 1-Figure 4 , the present invention is an autoclaved aerated concrete bubble quality control system, which has a slurry box body, a frame-shaped bracket 7 is arranged above the slurry box body, and an inner feeding pipe 10 is arranged downward in the middle of the frame-shaped bracket, The upper part of the inner feeding pipe is communicated with the slurry tank, and the inner feeding pipe is also provided with a pneumatic butterfly valve 11; the frame-shaped support is also provided with a synchronous lifting device, and the synchronous lifting device is connected downward with a grid pouring head, the grid pouring The head pours the slurry into the slurry box, the grid pouring head has a support frame 3, the support frame is connected with the synchronous lifting device, and a vibration motor 4 is arranged on the left and right sides of the support frame. A detachable mesh screen plate A2 and a mesh screen plate B1 are arranged in sequence from top to botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com