Dip soldering welding system for enamelled wire and operating method thereof

A welding system and working method technology, applied in welding equipment, metal processing, manufacturing tools, etc., can solve the problems of low pass rate, low welding efficiency, unstable welding temperature, etc., and achieve high production efficiency, high production precision, and work high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

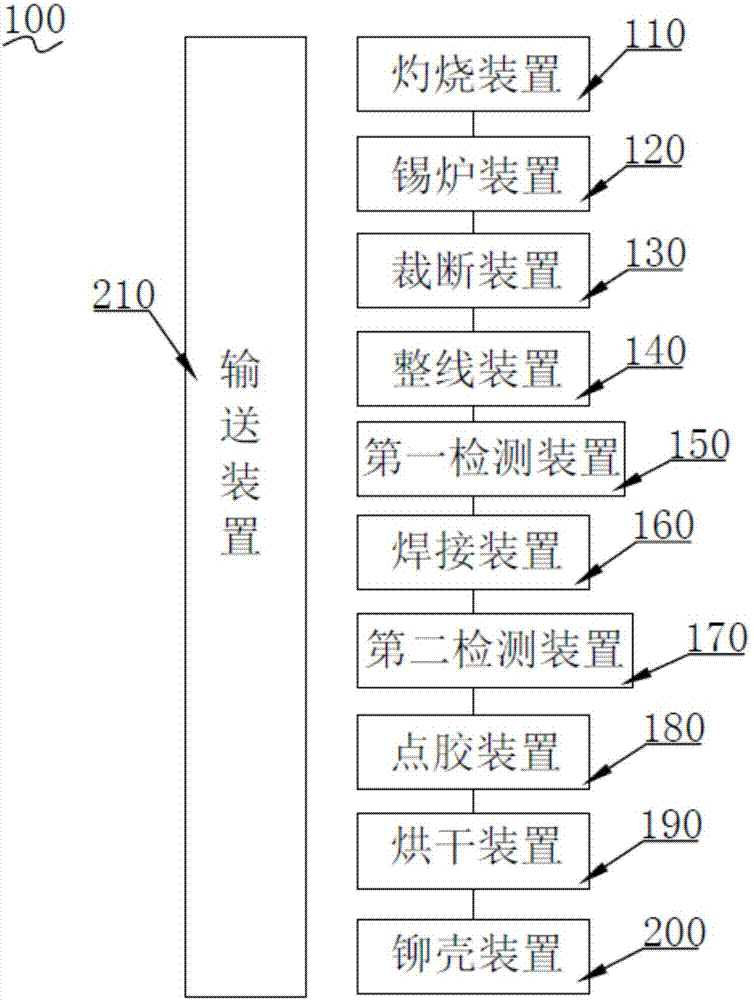

[0044] Such as figure 1 Shown is a schematic diagram of the present invention.

[0045]An enameled wire immersion tin welding system 100 is provided with a burning device 110 for removing enameled wire skin, a tin furnace device 120 for enameled wire tinning, a cutting device 130 for cutting enameled wire, and a wire finishing device 140 for finishing enameled wire , a first detection device 150 for detecting enameled wires, a welding device 160 for welding enameled wires, a second detection device 170 for detecting welded enameled wires, a dispensing device 180 for dispensing glue at welding positions, The drying device 190 for drying and dispensing and the riveting device 200 for riveting after drying; the enameled wire sequentially passes through the burning device 110, the tin furnace device 120, the cutting device 130, the whole line device 140, the first detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com