Assembling type U-shaped groove foundation for building and construction method thereof

A U-shaped trough and assembled technology, which is applied in infrastructure engineering, construction, etc., can solve the problems of bulky, low construction cost, inconvenient handling or transportation for operators, and achieve convenient construction, ensure stability, handling and transportation Convenient and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

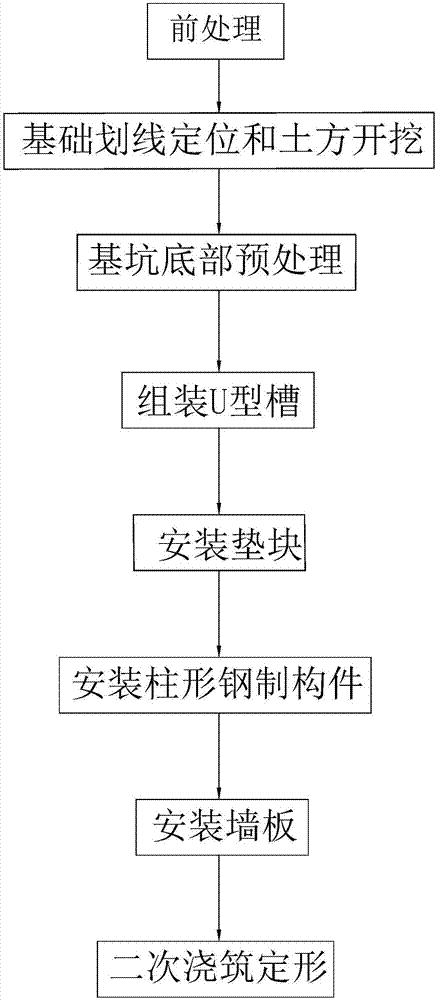

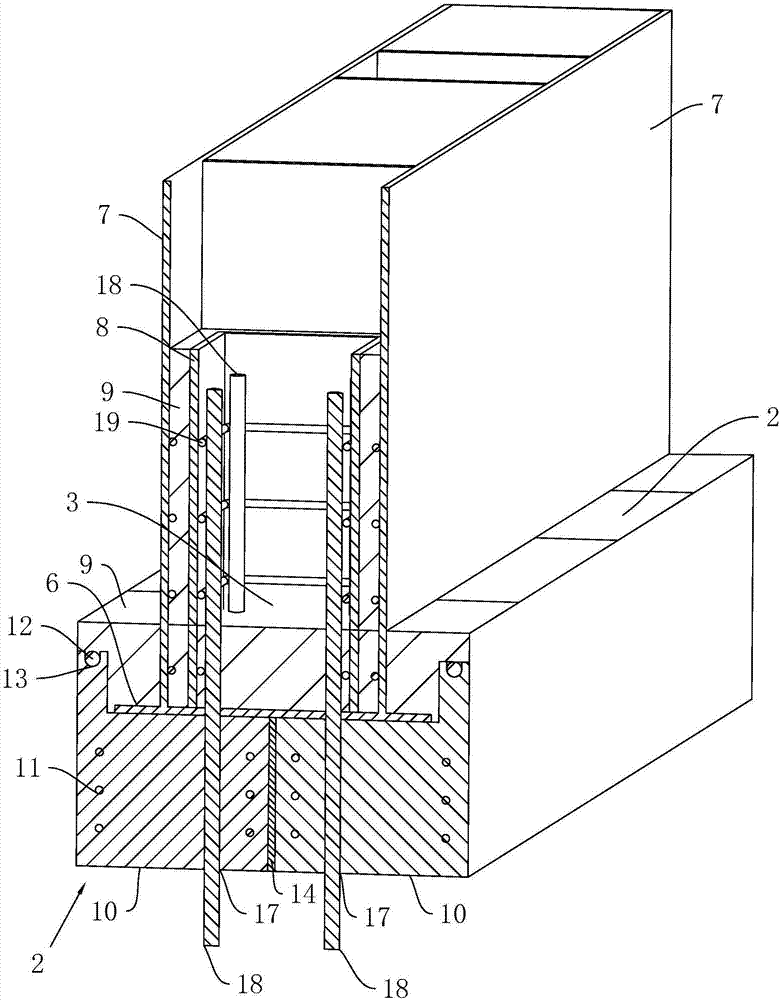

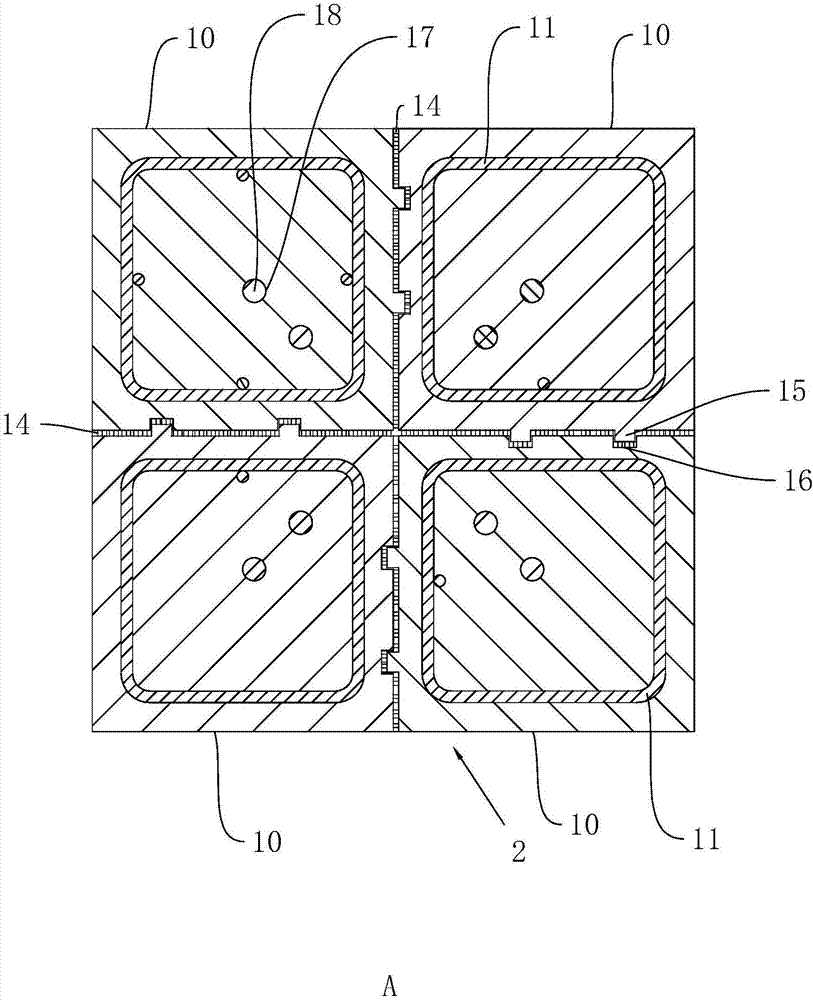

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0043] Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

[0044] A kind of prefabricated building U-shaped groove foundation, such as figure 2 As shown, it includes a U-shaped groove 2 arranged on the foundation, and a cavity groove 3 for inserting an assembled wallboard 7 is opened on the U-shaped groove 2, and a cushion block 6 is installed on the bottom surface of the cavity groove 3, and the cushion block 6 is fixed with a cylindrical steel member 8 for connecting the assembled wallboard 7, and concrete 9 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com