Heatproof electric rice cooker cover inner wall coating

A technology for electric rice and pot lids, which is applied in the direction of fireproof coatings and coatings, which can solve the problems of easy rust, reduced service life of coatings, and poor heat resistance of coatings, and achieves improved heat resistance, leveling, and hardness. and outstanding heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

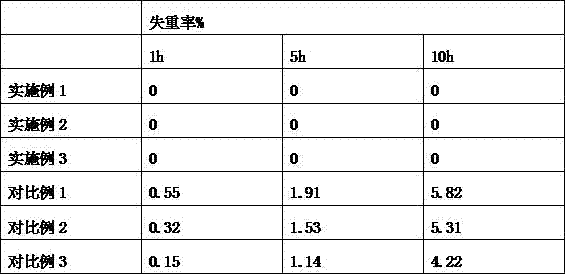

Examples

Embodiment 1

[0018] A heat-resistant electric rice cooker cover inner wall coating, made of the following components in parts by weight: 56 silicone emulsions, 15 polyols, 0.5 dispersants, 0.1 wetting agents, 12 fillers, 0.1 leveling agents, film-forming aids Agent 0.5, modified montmorillonite 5, defoamer 0.2, deionized water 40 containing ethyl cellulose; the preparation method of the modified montmorillonite containing ethyl cellulose is: take montmorillonite as raw material, It is obtained by using ethyl cellulose as a modified filler, reacting under microwave radiation conditions, separating and purifying, and freeze-drying.

[0019] Further, the solid content of the silicone emulsion is 45%, and the pH value is 8.5.

[0020] Further, the polyhydric alcohol is one or a mixture of ethyl butyl propylene glycol, trimethylolpropane, and trimethylolethane.

[0021] Further, the dispersant is glyceryl tristearate.

[0022] Further, the defoamer is a silicone defoamer.

[0023] Further, t...

Embodiment 2

[0028] A heat-resistant electric rice cooker cover inner wall coating, made of the following components in parts by weight: 66 silicone emulsions, 18 polyols, 1.2 dispersants, 1.5 wetting agents, 15 fillers, 0.3 leveling agents, film-forming aids Agent 0.8, modified montmorillonite 8, defoamer 0.4, deionized water 50 containing ethyl cellulose; the preparation method of the modified montmorillonite containing ethyl cellulose is: take montmorillonite as raw material, It is obtained by using ethyl cellulose as a modified filler, reacting under microwave radiation conditions, separating and purifying, and freeze-drying.

[0029] Further, the solid content of the silicone emulsion is 45%, and the pH value is 8.5.

[0030] Further, the polyhydric alcohol is one or a mixture of ethyl butyl propylene glycol, trimethylolpropane, and trimethylolethane.

[0031] Further, the dispersant is glyceryl tristearate.

[0032] Further, the defoamer is a silicone defoamer.

[0033] Further, t...

Embodiment 3

[0038] A heat-resistant rice cooker lid inner wall coating, made of the following components in parts by weight: silicone emulsion 60, polyol 16, dispersant 0.8, wetting agent 0.5, filler 13, leveling agent 0.2, film-forming aid Agent 0.6, modified montmorillonite 7, defoamer 0.3, deionized water 45 containing ethyl cellulose; the preparation method of the modified montmorillonite containing ethyl cellulose is: take montmorillonite as raw material, It is obtained by using ethyl cellulose as a modified filler, reacting under microwave radiation conditions, separating and purifying, and freeze-drying.

[0039] Further, the solid content of the silicone emulsion is 45%, and the pH value is 8.5.

[0040] Further, the polyhydric alcohol is one or a mixture of ethyl butyl propylene glycol, trimethylolpropane, and trimethylolethane.

[0041] Further, the dispersant is glyceryl tristearate.

[0042] Further, the defoamer is a silicone defoamer.

[0043] Further, the wetting agent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com