Pipe hot air heating box and pipe hot air heating device thereof

A hot air heating and practical technology, which is applied in the field of hot air heating boxes for pipes, can solve the problems of troublesome replacement operation, unreasonable structure, and small heating port area in the air inlet area C, so as to achieve a good utilization rate of heat energy and is suitable for industrial production , the effect of convenient technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

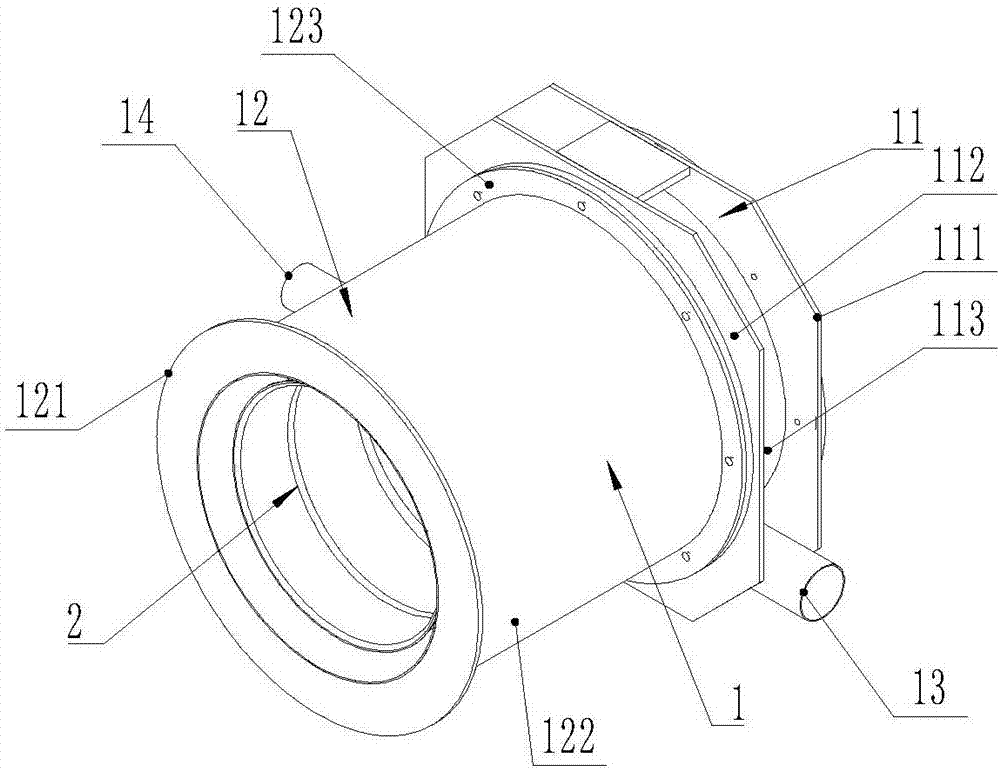

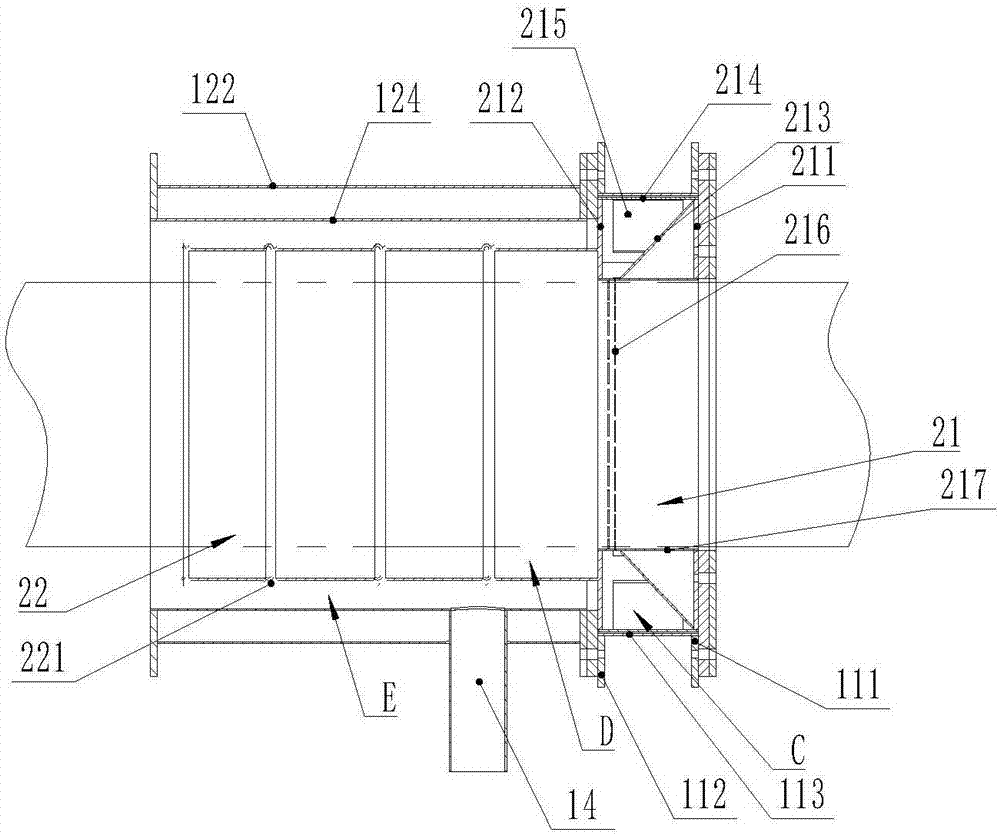

[0031] like Figure 1 to Figure 7 As shown, a hot air heating box for pipes includes an inner cylinder 2 and an outer cylinder 1, and the outer cylinder 1 includes a concentrically connected air inlet cylinder section 11 and a return air cylinder section 12, and the air inlet cylinder section 11 is provided with Air inlet pipe mouth 13, described air return tube section 12 is provided with return air pipe mouth 14, as figure 1 and image 3 , Figure 4 As shown, the air return cylinder section 12 includes an inner air return cylinder 124 and an outer air return cylinder 122 fixed concentrically, and a heat insulating material is arranged between the inner air return cylinder 124 and the outer return air cylinder 122 or vacuum environment. The setting of the vacuum environment is relatively difficult, but this method can also be used, that is, a negative pressure tuyere can be set on the external return air cylinder 122 to suck air to form a vacuum environment. Generally, hea...

Embodiment 2

[0038] This embodiment discloses a hot-air heating device for pipes. The hot-air heating device uses the above-mentioned hot-air heating box for pipes. The air duct opening 14 is connected to the air return port of the blower fan 4 through the air return duct 7, and the air inlet duct 6 is provided with a heater 5 which heats the air in the air inlet duct 6. Generally, the heater 5 adopts electric heating. device 5.

[0039] The working principle of this embodiment is: the pipe moves axially through the through opening, and the fan 4 sends the heated hot air into the air inlet nozzle 13, and then enters the heating chamber. Due to the existence of the annular shrinking cone surface 213, the hot air Gather, the temperature increases, and then form a hot air knife through the heating tuyeres 216, so that the surface of the pipe will be heated, and the hot air will flow into the heat preservation chamber along the gap between the pipe and the through hole 15, and then the pipe wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com