Two-degree-of-freedom power vibration absorption boring bar

A technology of dynamic vibration reduction and dynamic shock absorber, which is applied in the direction of boring bars, etc., can solve the problems of reducing the quality of the tool bar and the impossibility of fully exerting its performance, and achieves good amplitude-frequency response characteristics, improved vibration reduction effect, and high amplitude The effect of stable frequency response characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

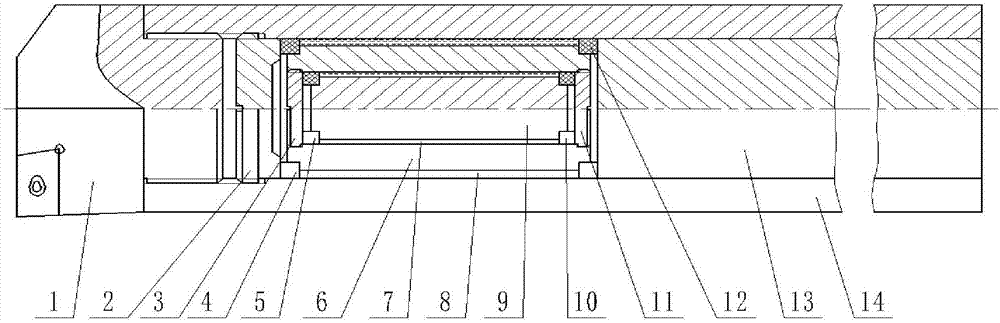

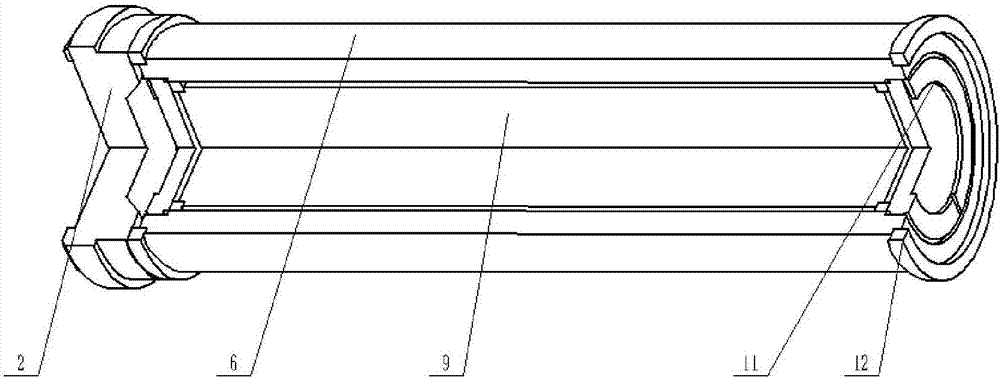

[0014] The present invention will be further explained below in conjunction with the drawings and embodiments:

[0015] A dual-degree-of-freedom dynamic damping boring bar according to an embodiment of the present invention, see Figure 1~2 , The boring bar mainly includes a cutter head 1, an adjusting stud 2, a compound structure cutter bar and a dual-degree-of-freedom dynamic shock absorber. The cutter head is made of ferromagnetic damping alloy FeCr3Mo. The composite structure cutter bar is composed of a metal sleeve 14 and a carbon fiber rod 13. The carbon fiber rod 13 is connected to the rear end of the metal sleeve 14 by an adhesive. The adhesive not only has the function of connecting the metal sleeve and the carbon fiber rod, but also has good damping characteristics. It can consume the vibration energy of the boring bar and reduce the deformation of the metal sleeve and the carbon fiber bar. The adjusting stud 2 and the metal sleeve 14 are screwed to the inner front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com