Method for determination of lead and cadmium content in silver jewelry

An element content, silver jewelry technology, applied in the field of silver jewelry element content detection, can solve the problems of low lead and cadmium element content, inaccurate test results, inability to obtain accurate data, etc., and achieves high recovery rate and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

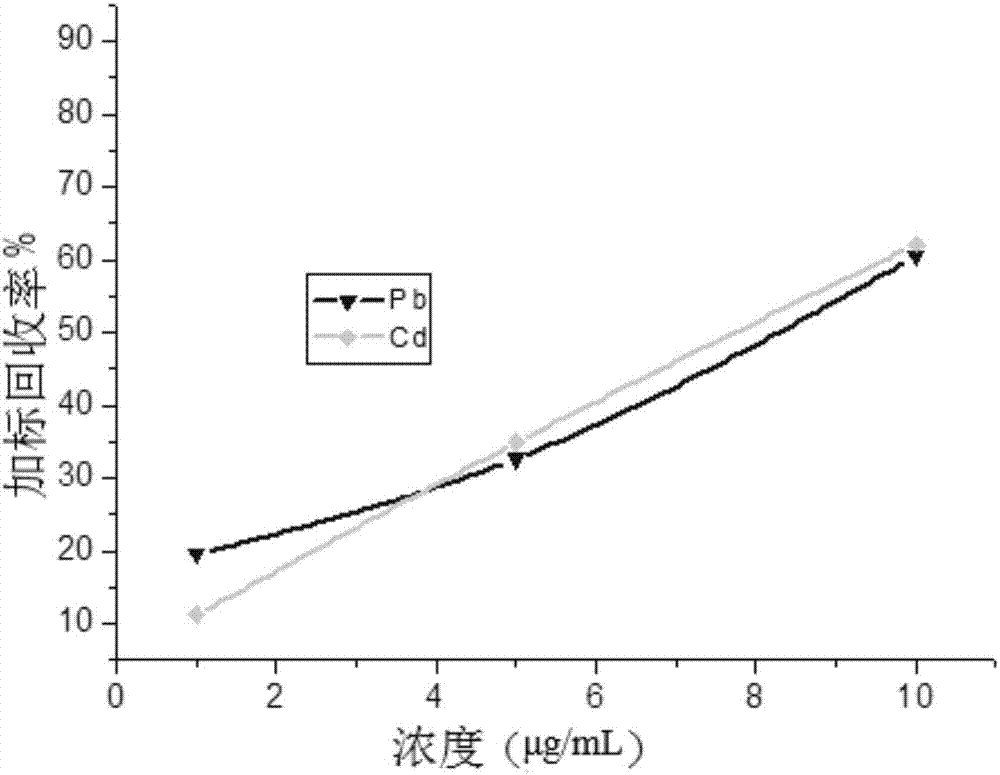

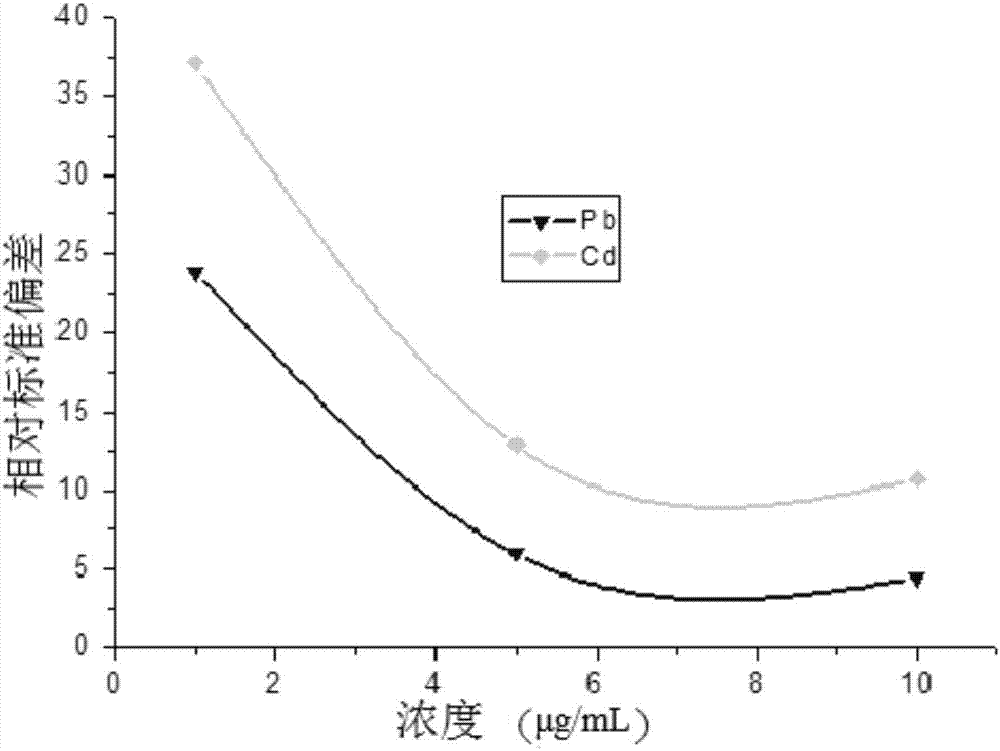

[0027] Example 1: Adsorption experiment of lead and cadmium elements by silver chloride in the national standard GB / T 21198.5-2007 test method.

[0028] Prepare a mixed standard solution with a content of 50 μg / mL of lead and cadmium, and then use the mixed standard solution of lead and cadmium to prepare a series of mixed standards of lead and cadmium with a concentration of 0, 1.0, 2.0, 3.0, 5.0, and 10.0 μg / mL The solution is measured on the machine, and the appropriate curve equation is selected to establish a working curve.

[0029] Use nitric acid and high-purity silver (silver content higher than 99.99wt%) to prepare 50μg / mL silver-containing matrix solution, then measure 10.00mL of 50μg / mL silver-containing matrix solution and place it in a 50mL beaker, add 1.00, 5.00, 10.00mL respectively After adding 15mL of concentrated nitric acid, slowly heating to drive out the nitrogen oxides. Then slowly drop 2mL of 37wt% hydrochloric acid solution, after standing still for 2 ...

Embodiment 2

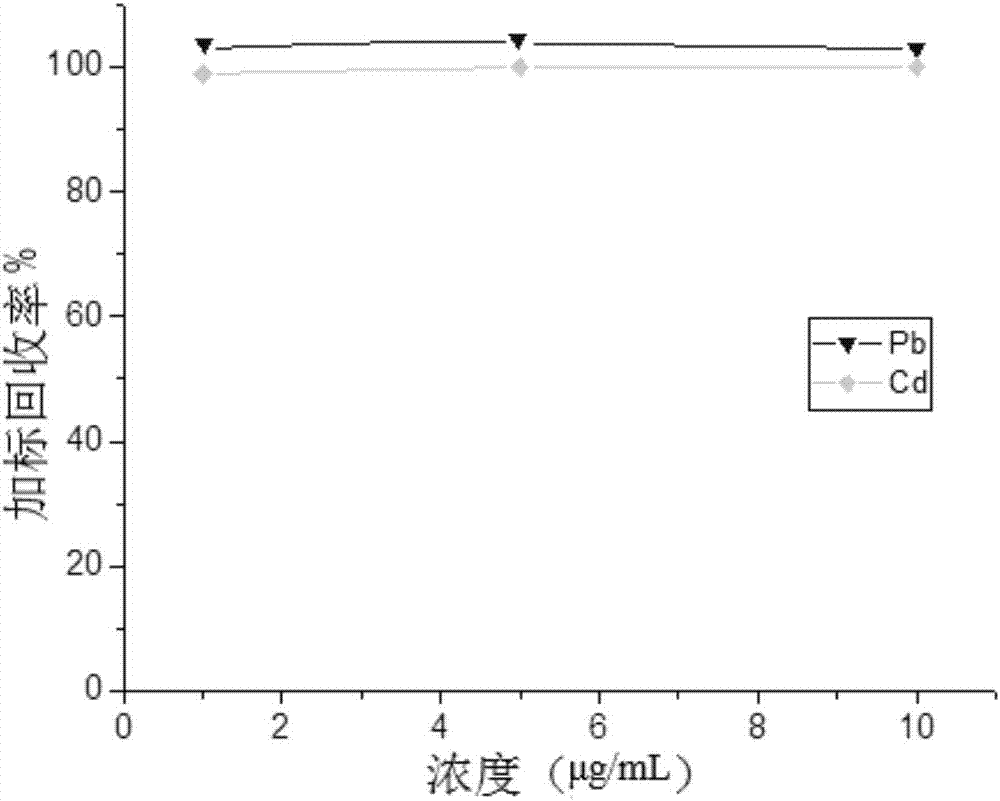

[0039] Embodiment 2: the experiment of measuring lead, cadmium element content in the silver solution by thiocyanate solution.

[0040] Prepare a mixed standard solution with a content of 50 μg / mL of lead and cadmium, and then use the mixed standard solution of lead and cadmium to prepare a series of mixed standards of lead and cadmium with a concentration of 0, 1.0, 2.0, 3.0, 5.0, and 10.0 μg / mL The solution is measured on the machine, and the appropriate curve equation is selected to establish a working curve.

[0041] Use nitric acid and high-purity silver (silver content higher than 99.99wt%) to prepare 50μg / mL silver-containing matrix solution, then measure 10.00mL of 50μg / mL silver-containing matrix solution and place it in a 50mL beaker, add 1.00, 5.00, 10.00mL respectively After adding 15mL of concentrated nitric acid to the standard solution of the mixed series of two elements, slowly heat to drive away the nitrogen oxides. Then slowly drop into 2mL of 0.25g / mL potas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com