A method for targeted capture sewage treatment

A sewage treatment method and targeted capture technology, which can be used in water/sewage treatment, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

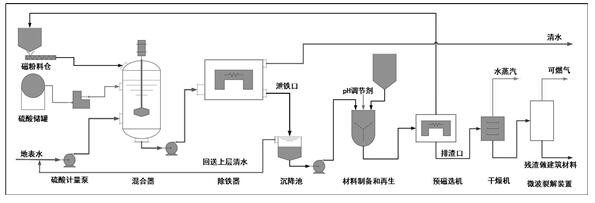

[0045] Example 1: Treatment Techniques on Ground Surfaces Containing Clay Particles and Organic Matter

[0046] See the specific process figure 1 .

[0047] For most surface water, the main pollutants are solid particles and microorganisms dispersed in the water, and organic matter adsorbed or dissolved in the water. Most of these pollutions are negatively charged, and magnetic particles with positive charges on the surface should be added in the process (for example, ferric oxide is positively charged below pH 6 and negatively charged above 6, and the charge on the surface of the magnetic particles can be realized by adjusting the pH. sex). The raw water is ordinary river water with a turbidity of 200 NTU. Select 1000-mesh selected magnetite powder to activate it by adding a small amount of sulfuric acid and ammonia water. The ratio of sulfuric acid and ammonia water is 2:1, and then use magnetic separation and transmission equipment Add the magnetic and positively charged...

Embodiment 2

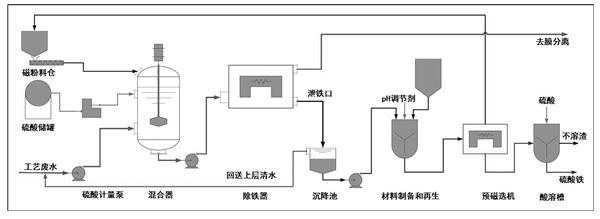

[0048] Example 2: Removal of polytetrafluoroethylene microparticles in polytetrafluoroethylene dispersed resin production wastewater

[0049] See the specific process figure 2 .

[0050] Fluorine-containing emulsifiers such as perfluorooctanoic acid are indispensable in the production of PTFE dispersion resins. These fluorine-containing surfactants not only have high production costs, but also cause serious harm to the environment due to their poor biocompatibility. When using membrane separation to recover PFOA in wastewater, the polytetrafluoroethylene nanoparticles remaining in the wastewater will block the membrane components, resulting in separation failure. The turbidity of the raw water is 18.9NTU. Select 1000-mesh selected magnetite powder to activate it by adding a small amount of sulfuric acid and ammonia water. The ratio of sulfuric acid and ammonia water is 0.5:1, and then use magnetic separation and transmission equipment to make it magnetic. And the magnetite ...

Embodiment 3

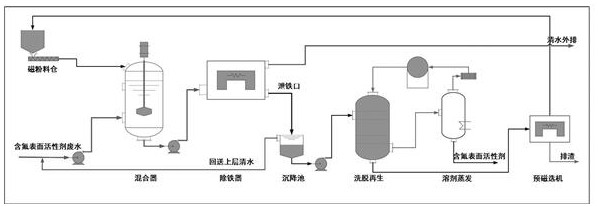

[0051] Example 3: Recovery process of fluorine-containing surfactant in fluorine-containing organic polymer production wastewater

[0052] See the specific process image 3 .

[0053] In the production of fluorine-containing polymerization, fluorocarbon surfactants are often used in large quantities as emulsifiers and dispersants, and most of them will be discharged with wastewater after use. These fluorine-containing surfactants not only have high production costs, but also cause serious harm to the environment due to their poor biocompatibility. Separation of fluorosurfactants using membranes is extremely costly to operate and may solve the technical problem of membrane clogging caused by residual fluoropolymer particles in wastewater. The content of perfluorooctanoic acid in tetrafluoroethylene condensed wastewater is 20ppm. The nano-ferric oxide synthesized by co-precipitation method is selected as the core, and the surface is coated with silicon dioxide. According to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com