Method for preparing magnetic composite biobased supported phosphotungstic acid catalyst

A magnetic composite microsphere, bio-based technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of composite microsphere carrier damage and unfavorable immobilization And other problems, to achieve the effect of easy functional modification, not easy to leak, good magnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

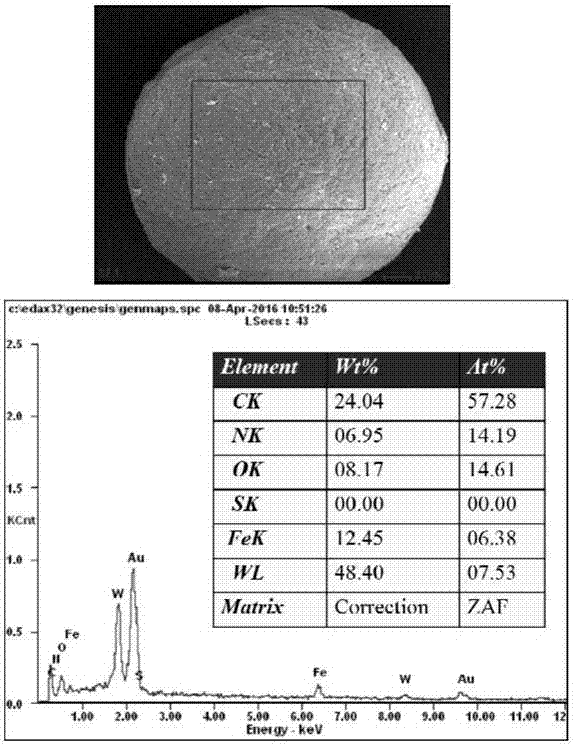

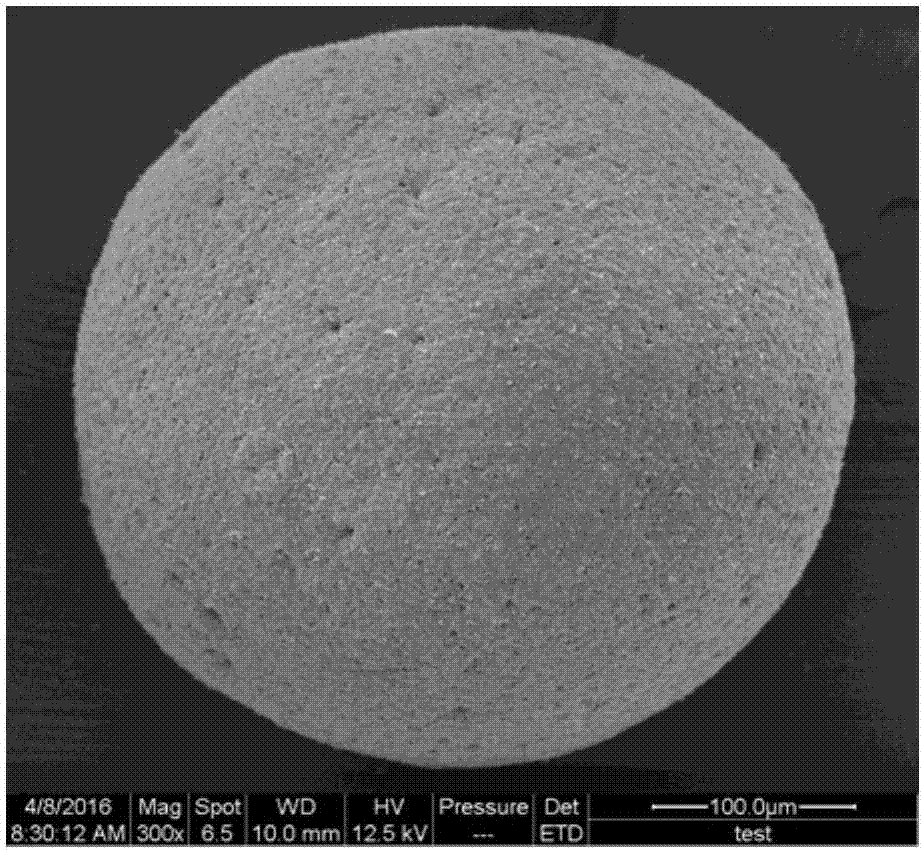

[0026] Put 5g of cellulose into 66g of ionic liquid to dissolve, add 40mL (1mg / 1.6mL) graphene oxide solution and mix evenly, mechanically stir in the transformer oil by high-speed electric stirring equipment, and immobilize into balls by reverse-phase suspension technology, After repeated washing with absolute ethanol and 4% hydrochloric acid, the obtained composite mesoporous microspheres were dried for future use. Next, put 5g of dry composite mesoporous microspheres into 5mL of epichlorohydrin and 10mL of 3mol / L sodium hydroxide solution, react on a shaking table at 25°C for 8h, and wash and filter the microspheres repeatedly to the pH of the filtrate after the reaction To be neutral, disperse the microspheres into an aqueous solution of triethylenetetramine and sodium carbonate and react in a water bath at 50°C for 8h. After the reaction is finished, it is washed with deionized water to remove the remaining reaction liquid, and the obtained amine-functionalized composite ...

Embodiment 2

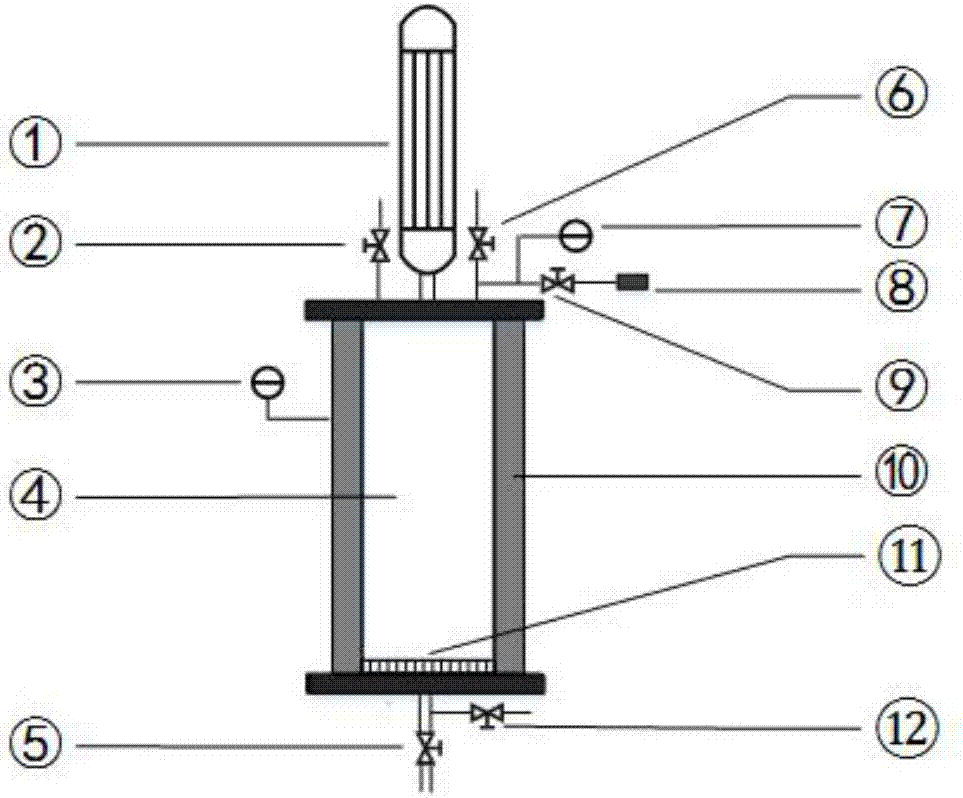

[0028] Open the negative pressure valve ⑨, start the negative pressure pump ⑧, make the negative pressure in the tank ④ reach -0.08~-0.09MPa, open the sampling valve ②, and remove 3.81g ferrous chloride, 9.75g ferric chloride and 200mL Ionized water is sucked into the tank body ④, the sampling valve ② is closed, the nitrogen valve is opened, and the ferric chloride and ferric chloride are fully dissolved in the deionized water through the cavitation generated by the negative pressure equipment, and the Fe in the mixed solution is 3+ with Fe 2+ The molar ratio is 2:1, close the nitrogen valve, open the injection valve ②, inhale 5g of modified composite microspheres into the tank ④, close the injection valve ②, open the nitrogen valve for 1h, and keep the tank ④ at the same time. Negative pressure is still -0.08~-0.09MPa, close the nitrogen valve, open the sampling valve ② Inhale ammonia water until the pH of the mixture is 9, heat the equipment to 60°C through the heating syste...

Embodiment 3

[0030]Dissolve 2g of phosphotungstic acid in 20mL of absolute ethanol medium, add 2g of amine-functionalized magnetic composite microspheres, control the temperature at 60°C, and immobilize for 2 hours, stop stirring after the reaction is complete, and filter off the excess reaction solution , Dry the catalysts that are used in many fields such as catalyzed organic reactions, medicinal chemistry and magnetic materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com