Water electrolysis catalysis material having palladium-nickel nanometer alloy structure

A technology of catalytic materials and nano-alloys, which is applied in the field of electrolytic water catalytic materials, can solve the problems of reduced catalytic efficiency, poor stability of transition metals, poor stability of electrocatalytic electrodes, and poor cycle performance, so as to facilitate diffusion and gas desorption , the effect of preventing agglomeration, good stability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

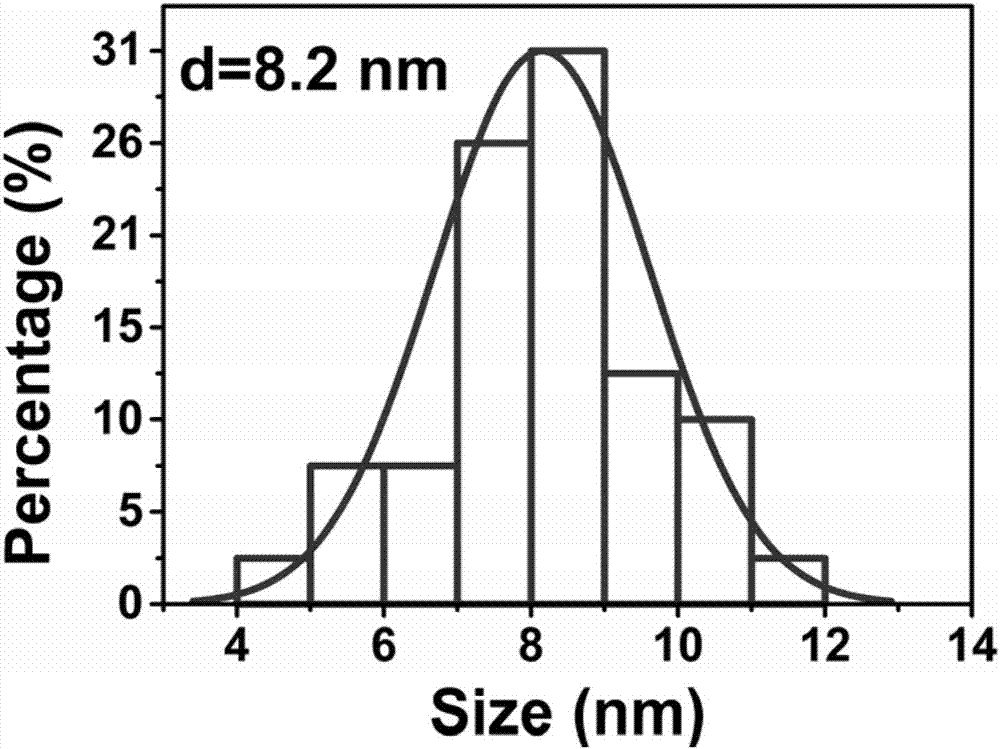

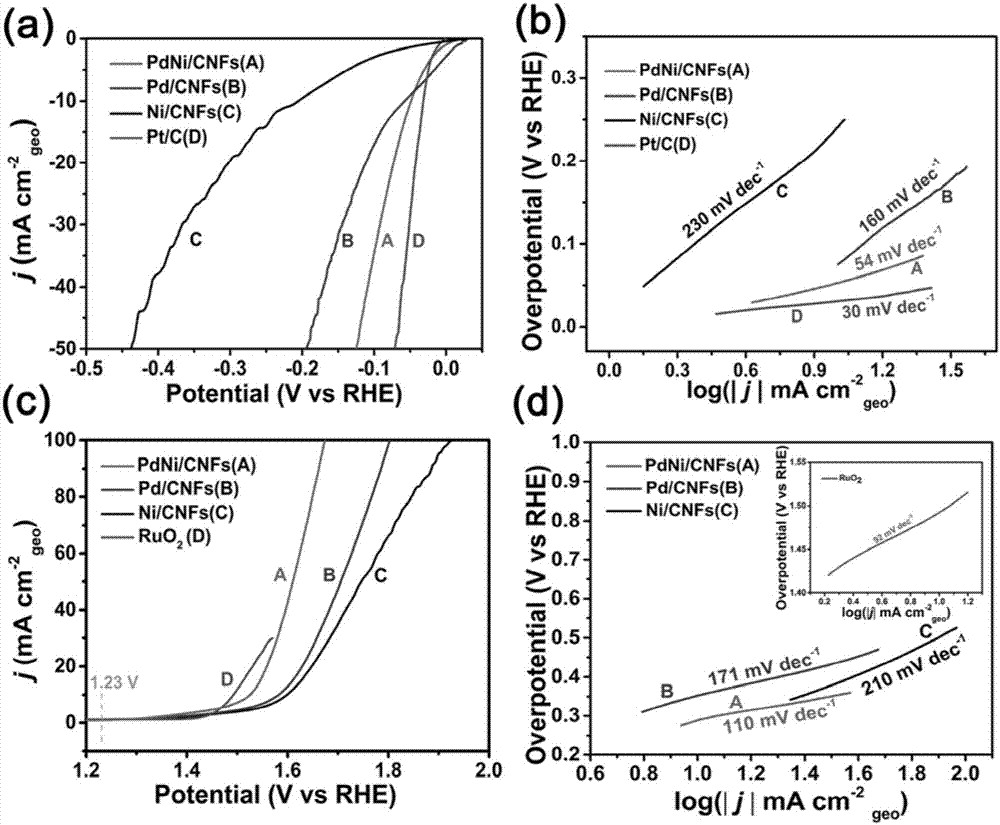

[0033] An electrolytic water catalytic material with a palladium-nickel nano-alloy structure, the electrolytic water catalytic material is composed of a catalytic active substance and a carrier, the catalytic active substance is a palladium-nickel alloy nano particle, and the carrier is an ultrafine carbon fiber. The loading amount of the catalytic active substance on the carrier is 5-20wt%, and the size of the palladium-nickel alloy nanoparticles is 7-10nm. The fineness of the ultrafine carbon fiber is 50-1000nm.

[0034] The preparation method comprises the following steps:

[0035] 1) The superfine carbon fiber precursor is made into a spinning solution with a mass concentration of 5-15% with deionized water, and the precursor of the palladium-nickel alloy is respectively dissolved in the spinning solution, and then the spinning solution is electrospun Superfine fibers are prepared by the method; during electrospinning, the spinning voltage is controlled to be 8-20kV, the ...

specific Embodiment

[0039] Get 0.05g palladium chloride and 0.1g nickel nitrate and join in 11.2g polyvinyl alcohol aqueous solution (wherein the mass concentration of polyvinyl alcohol is 10%), adopt electrospinning method to this solution to spin then, control spinning voltage 12kV, the distance from the receiving device to the spinning needle is 12cm (that is, the receiving distance is 12cm), and the solution flow rate is 0.5mL / h, that is, ultrafine fibers are obtained.

[0040] Add 0.5g of superfine fiber to the corundum boat, and then place the corundum boat in the middle of the tube furnace;

[0041] First, the temperature was raised to 230° C. at 5° C. / min in air and maintained for 1 hour. One hour after the start of heating, argon (150 sccm) was bubbled. Then the sample was heated to 900°C at the same heating rate, kept for 8 hours, and finally cooled to room temperature under the protection of argon to obtain a palladium-nickel alloy structure / ultrafine carbon fiber hybrid material. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com