Special gas fire-extinguishing device for lithium-ion battery box and implementation method for fire extinguishing

A lithium-ion battery, fire extinguishing device technology, applied in electrical components, secondary batteries, secondary battery repair/maintenance, etc. The development of fire and other problems, to achieve the effect of small size, low pressure, and random shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

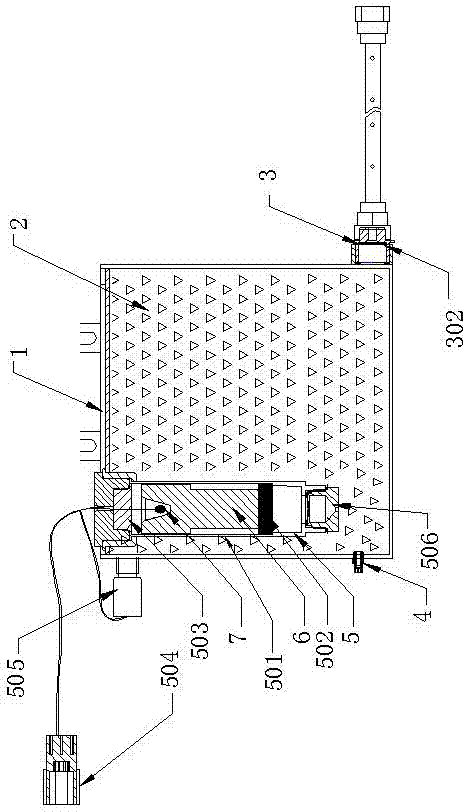

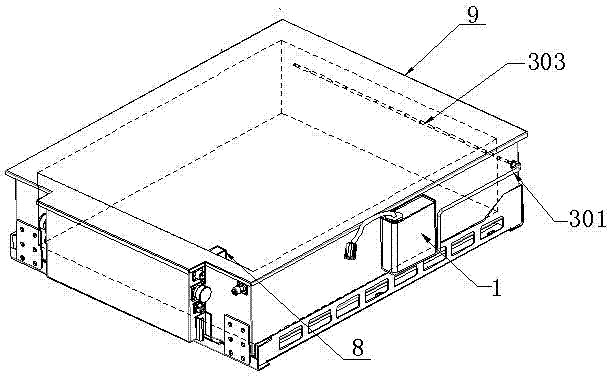

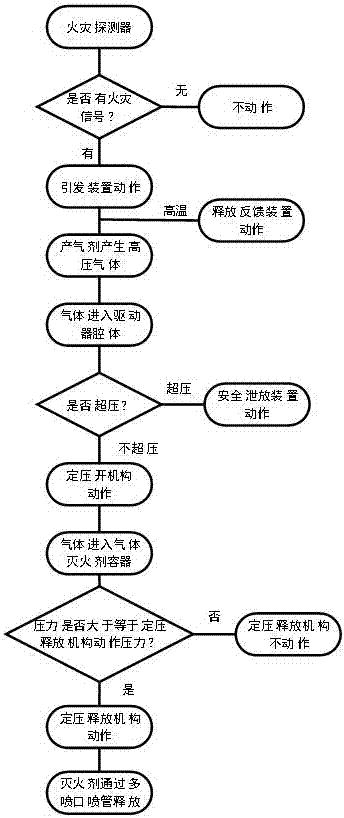

[0023] The gas fire extinguishing agent container 1 has a rectangular parallelepiped structure, and is welded by upper and lower shells. The gas production driver 5 is fixed inside the upper shell. The lower shell of the gas fire extinguishing agent container 1 is provided with a fire extinguishing agent filling port and a fire extinguishing dose release port. The set pressure of the gas fire extinguishing agent container 1 is 1.5 MPa, and the Novec1230 gas fire extinguishing agent 2 is filled through the fire extinguishing agent filling port, and is sealed with an openable air inlet locking device 4 after filling. The working temperature range of Novec1230 gas fire extinguishing agent 2 is -40℃~120℃, the pressure inside the gas fire extinguishing agent container 1 is the saturated vapor pressure of Novec1230 gas fire extinguishing agent 2, and the saturated vapor pressure of Novec1230 gas fire extinguishing agent 2 is about 0MPa at 20℃ The boiling point temperature of Novec12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com