Rapid film forming fluid dressing containing N-glycosylated chitosan as well as preparation and application of rapid film forming fluid dressing

A chitosan and sugar-based technology is applied in the field of biomedical dressing and its preparation, which can solve the problems of pain, unfavorable wound healing, easy tearing and touching the wound surface, etc., and achieves good air permeability and water resistance, good biological safety, The effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of N-glycosylated chitosan: Weigh 4.0g of chitosan, add 200mL of 1% acetic acid aqueous solution in volume concentration, and stir for 0.5h at room temperature (25-30°C). When it is fully dissolved, add 4.0 chitosan. Sugar amino equivalent fructose, after magnetic stirring reaction at 30~35℃ for 7h, add 1.7g sodium borohydride and reduce at room temperature for 24h, finally terminate the reaction with 95% volume concentration ethanol aqueous solution, and wash the precipitated product with absolute ethanol for 3~ After 4 times, the precipitate was obtained by centrifugation, and dried under vacuum at 40°C to obtain 7.5 g of N-glycosylated chitosan, which was stored in a desiccator for later use.

Embodiment 2

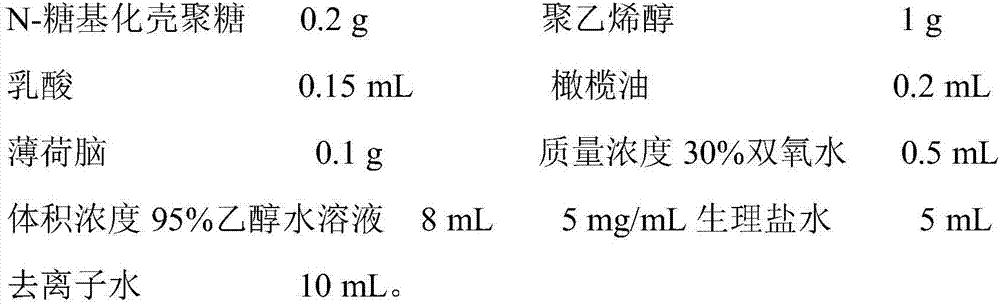

[0036] The fast film-forming fluid dressing containing N-glycosylated chitosan is made of the following raw materials:

[0037]

[0038] The specific steps of its preparation are:

[0039] (1) Preparation of the base solution: Weigh 0.2g of N-glycosylated chitosan and dissolve it in 5mL of 5mg / mL saline, then add 0.15mL of lactic acid and stir to dissolve to obtain a base solution with a concentration of 40mg / mL ;

[0040] (2) Preparation of membrane solution: Weigh 1g of polyvinyl alcohol (polymerization degree 1750±50), add it to 10mL of deionized water, heat and stir at 95℃ for 2~3h until it is completely dissolved, and obtain a mass concentration of 10% polyvinyl alcohol Membrane liquid

[0041] (3) Add the membrane solution prepared in step (2) to the bottom solution of step (1), mix the two evenly, and then add 0.2 mL of olive oil, 0.1 g of menthol, 0.5 mL of 30% hydrogen peroxide by volume and volume The concentration of 95% ethanol aqueous solution is 8 mL, the stirring spee...

Embodiment 3

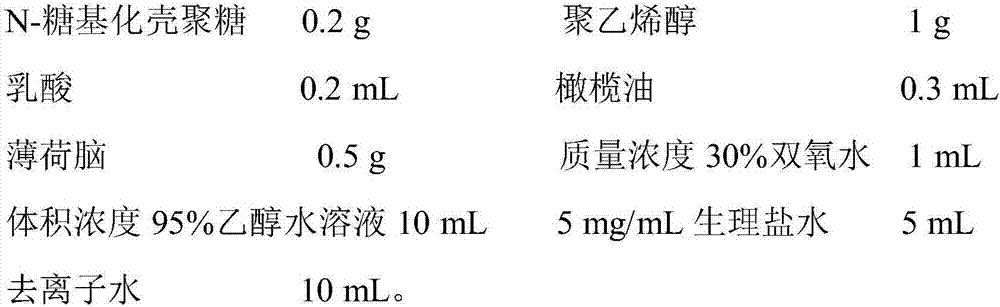

[0043] The fast film-forming fluid dressing containing N-glycosylated chitosan has the following raw material composition and ratio:

[0044]

[0045] The preparation method is:

[0046] (1) Preparation of the base solution: Weigh 0.2g of N-glycosylated chitosan and dissolve it in 5mL of 5mg / mL saline, add 0.2mL of lactic acid and stir to dissolve to obtain a base solution with a concentration of 40mg / mL ;

[0047] (2) Preparation of membrane liquid: Weigh 1g of polyvinyl alcohol, add it to 10mL of deionized water, heat and stir at 95°C for 2 to 3 hours until it is completely dissolved, and obtain a 10% polyvinyl alcohol membrane liquid by mass concentration;

[0048] (3) Add the membrane solution prepared in step (2) to the bottom solution of step (1), mix the two evenly, add 0.3 mL of olive oil, 0.5 g of menthol, 1 mL of 30% hydrogen peroxide by mass concentration, and 95% by volume. % Ethanol aqueous solution 10mL, stirring speed 500r / min, stirring and mixing uniformly to obtain 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com