A tunable metamaterial structure based on mechanical movement and its fabrication method

A manufacturing method and mechanical movement technology, applied in the direction of photomechanical equipment, pattern surface photolithography, instruments, etc., can solve the problems of low utilization efficiency of metamaterials and low success rate of metamaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical problem mainly solved by the present invention is that in the process of making metamaterials, it is necessary to make a mask plate for ultraviolet lithography and then carry out ultraviolet lithography. The fine structure leads to a low success rate of making metamaterials. The technical problem of inefficient use of materials.

[0041] Furthermore, a tunable metamaterial structure based on mechanical movement and a manufacturing method thereof are provided, so as to realize modulation or absorption of the resonant peak frequency of the metamaterial.

[0042] In order to better understand the technical solution of the present invention, the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

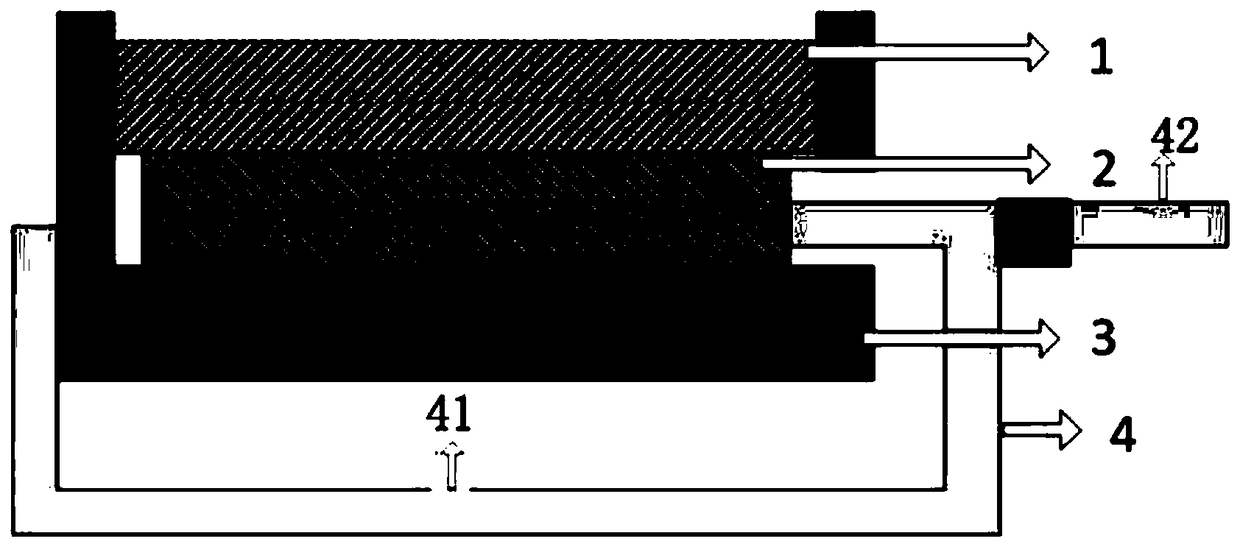

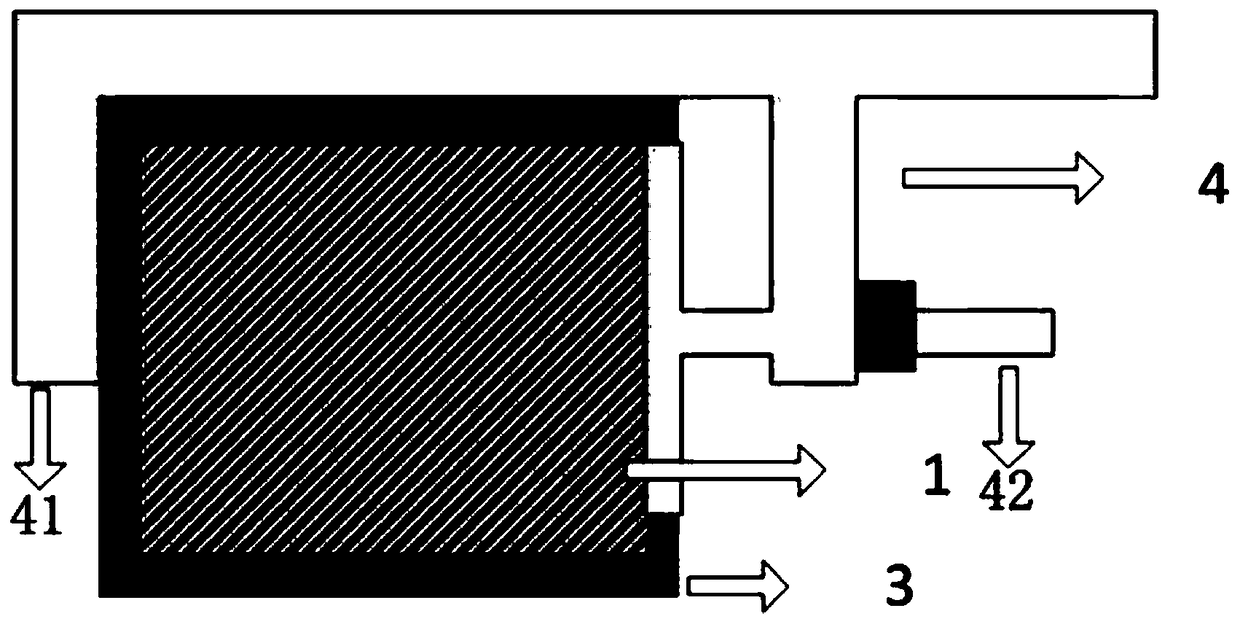

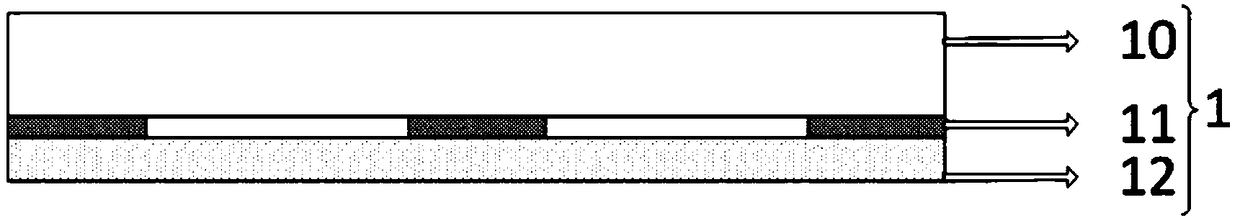

[0043] An embodiment of the present invention provides a tunable metamaterial structure based on mechanical movement, such as figure 1 , figure 2 as shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com