Method for quickly measuring ethyl carbamate in liquor samples in batches

A kind of urethane, rapid determination technology, applied in the field of analytical chemistry and food safety detection, can solve the problem of inconsistent pH in the optimal reaction of alanine dehydrogenase, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

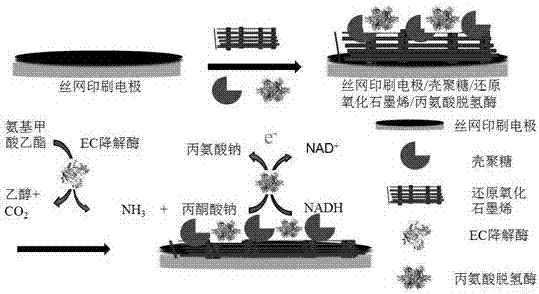

Method used

Image

Examples

Embodiment 1

[0020] Example 1 Determination of the optimal concentration of chitosan (CS) and reduced graphene oxide (RGO) in the preparation of screen-printed electrodes modified by alanine dehydrogenase (AlaDH)

[0021] When preparing alanine dehydrogenase-modified SPE, it is necessary to optimize the concentration of CS and RGO for immobilizing AlaDH to the electrode surface. The concentration of CS was optimized using the method of single factor experiment. First, prepare CS with mass concentrations of 0.1%, 0.2%, 0.3%, 0.4%, 0.5%, and 0.6%, add an appropriate amount of glycerol as a protective agent, stir evenly to remove foam, and place in a 4°C refrigerator for later use. Take 50 μL of CS solutions of different concentrations, mix them with 25 μL of 20 U / mL AlaDH respectively, and take 20 μL of the mixed solution and apply it dropwise on the surface of SPE. The prepared electrode was used to detect the standard EC solution according to the above two-stage reaction, and the current ...

Embodiment 2

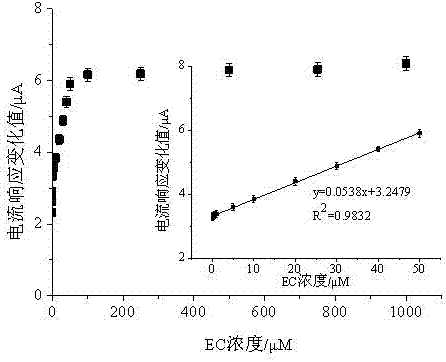

[0022] Embodiment 2. Determination of the optimum conditions for the first-stage reaction

[0023]The enzyme activity of EC degrading enzyme added to the reaction system was optimized by single factor test. Add 6, 8, 10, 12, 14, 16 U / mL of EC degrading enzymes to the solution containing 8mmol / L EC respectively. After reacting for 1 h, adjust the pH to 10 and add 50 mmol / L sodium pyruvate solution and 0.4 The mmol / L NADH solution was measured with a modified electrode, and the current response change value of NADH was recorded within 5 minutes of reaction time. When the addition amount of EC degrading enzyme was 16 U / mL, the change value of the electrode current response was the largest, and taking into account the use cost of the enzyme, the optimal addition amount of EC degrading enzyme was determined to be 16 U / mL.

[0024] The reaction time of the first stage was optimized by single factor experiment. Add 16 U / mL of EC degrading enzyme to the solution containing 8 mmol / L ...

Embodiment 3

[0025] Embodiment 3. Determination of the optimum conditions for the second stage reaction

[0026] After using the optimal conditions for the first-stage reaction, the concentration of NADH in the second-stage reaction system was optimized by single factor test. After the solution after the first stage reaction was adjusted to pH 10, NADH and 50 mmol / L sodium pyruvate were added at a concentration of 0.1, 0.2, 0.3, 0.4, 0.5, 0.75, 1.0 mmol / L, and the prepared alanine was used to remove The hydrogenase-modified screen-printed electrode was used for amperometric time measurement, and the optimal concentration of NADH was determined to be 0.5 mmol / L according to the size of the NADH response change value.

[0027] The concentration of sodium pyruvate added to the reaction system in the second stage was optimized by single factor experiment. After adjusting the pH of the solution after the first stage reaction to 10, add sodium pyruvate solution and 0.5 mmol / L NADH solution with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com