Circulation hot air drying box used for processing glazing powder

A technology of hot air drying and varnish powder, which is applied in drying, drying machines, lighting and heating equipment, etc., can solve the problems of short time required and low processing efficiency, and achieve the goal of improving utilization rate and drying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

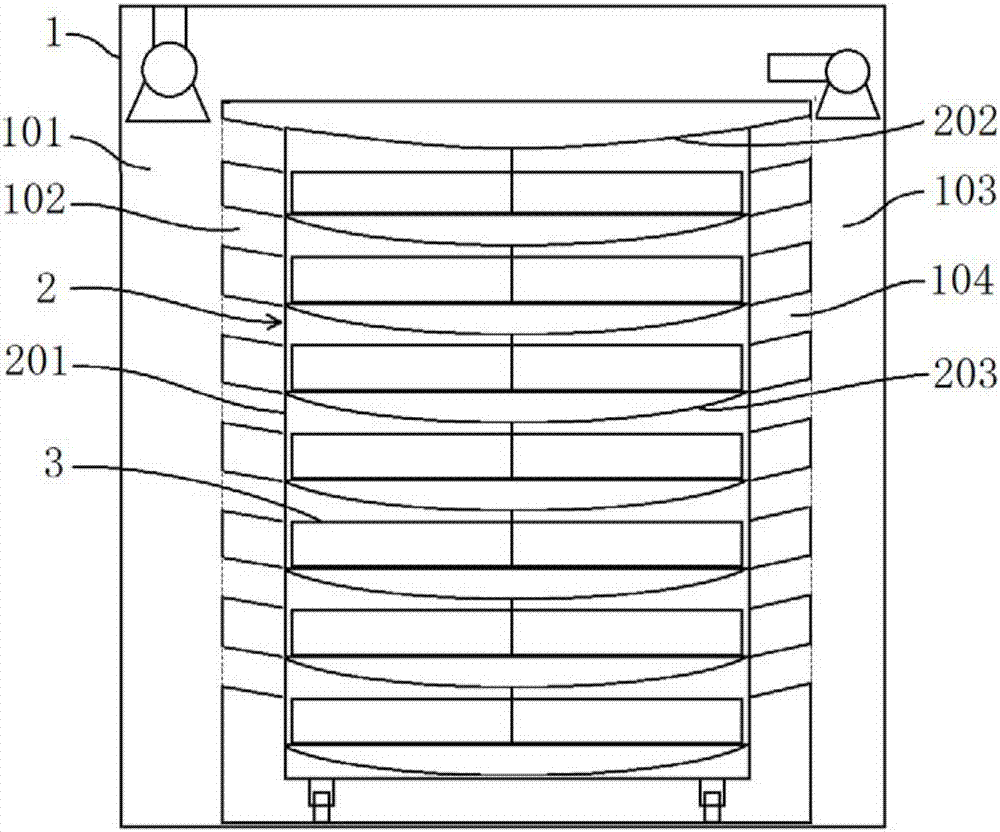

[0043] combine figure 1 A circulating hot air drying box for processing varnish powder in this embodiment includes a box body 1 and a drying car 2. The air inlet and moisture outlet of the box body 1 in this embodiment can adopt conventional designs, as long as Able to enter the wind laterally, without specific restrictions. An air inlet 101 is arranged on the left side of the box body 1 , and the air inlet 101 is arranged in a vertical direction, and an air inlet 102 is connected to the air inlet 101 . The air inlet 102 connects the air inlet channel with the inner cavity of the box, and the air inlet 102 is arranged horizontally, and there are a plurality of vertically spaced ones for allowing the drying wind to enter laterally to form a plurality of air inlets.

[0044] An air exhaust duct 103 is provided on the right side of the box body 1 , and transverse air exhaust outlets 104 are arranged at intervals on the air exhaust duct 103 . The air outlet 104 has the same arra...

Embodiment 2

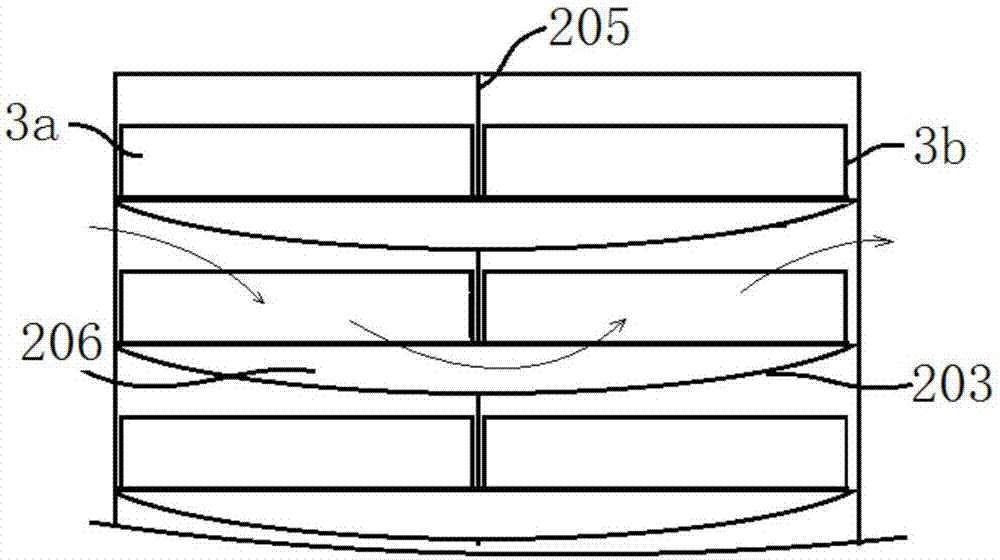

[0051] A circulating hot air drying box for processing varnish powder in this embodiment, its basic structure is the same as that of Embodiment 1, the difference is that: the air deflector 203 in this embodiment is arc-shaped, and with respect to the partition The plate 205 is symmetrical, and the lowest point of the air guide plate 203 is in contact with the partition plate 205 .

[0052] Since the air deflector 203 is set in an arc shape, the closer to the position of the partition 205, the smaller the space above the tray 3, and due to the existence of the partition 205, the pressure in this area is relatively high; while for the bottom of the tray 3 , the closer to the partition 205, the greater the distance between the air deflector 203 and the ground of the tray, and the greater the space of the air duct, which is more conducive to the circulation of hot air circulation.

Embodiment 3

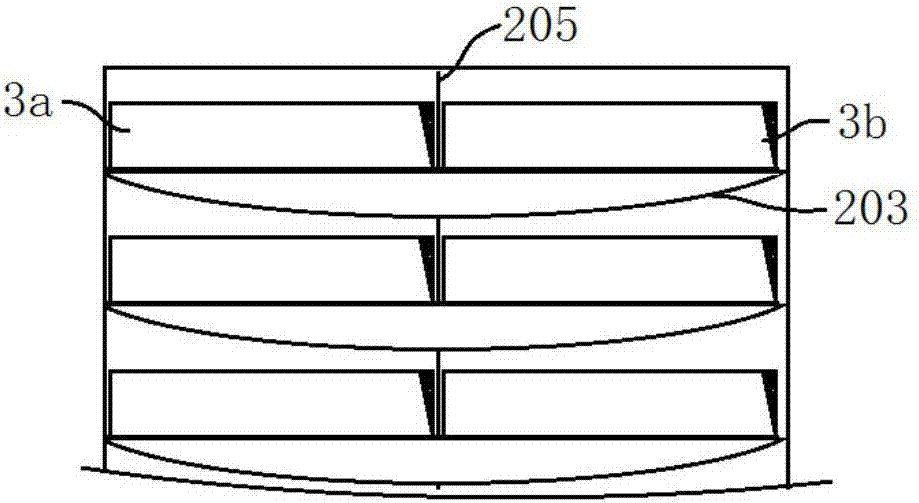

[0054] A circulating hot air drying box for processing varnish powder in this embodiment, its basic structure is the same as that of Embodiment 2, the difference is that: the air inlet 102 and the air outlet 104 are close to the side of the middle of the box body 1 It is inclined downward, and the distance between its end face and the inlet end face of the drying air duct 206 is 5mm.

[0055] Since the air intake effect must be ensured, and the air inlet 102 and the air outlet 104 are located on the box body, and the drying air duct 206 is located on the drying car, it is necessary to ensure that the relative positions between the two can cooperate with each other. Setting the gap to 5mm, on the one hand, can ensure the normal entry and exit of the drying car, and on the other hand, can make a small gap between the drying car and the air inlet and exhaust port, so that the hot air will not be lost. Due to the different specifications of the equipment, the gap can be set accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com