Composite and conductive polyimide/nickel fiber and preparation method thereof

A polyimide fiber and composite conductive technology, which is applied in fiber types, fiber treatment, textiles and papermaking, etc., can solve the problems of various chemical reagents, unsuitable for large-scale production, cumbersome steps, etc., and achieve good electromagnetic shielding performance , metal bonding performance is good, the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

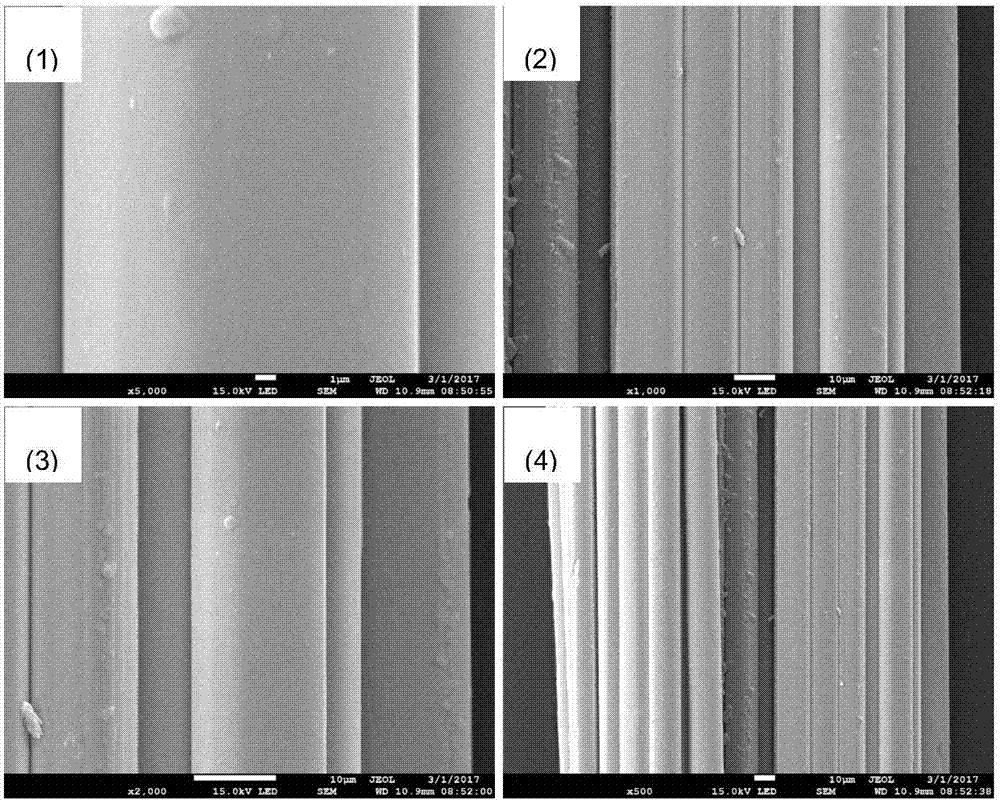

Embodiment 1

[0039] A: The polyimide fiber was etched in 1 mol / L potassium hydroxide solution at 20° C. for 1 min, and the fiber was cleaned with deionized water to obtain a surface-modified polyimide fiber.

[0040] B: Immerse the modified polyimide fiber obtained in step A in a palladium chloride solution with a mass concentration of 0.1g / L at 40°C for ion exchange. The ion exchange time is 10 minutes, and the fiber is cleaned with deionized water , to obtain polyimide fibers with palladium ions on the surface.

[0041] C: Immerse the palladium ion-containing polyimide fiber obtained in step B in a solution of dimethylaminoborane with a concentration of 0.1mol / L at 40°C for chemical reduction. The reduction time is 5 minutes, and the fiber is deionized with deionized water. After cleaning, polyimide fibers with an ultra-thin palladium layer on the surface are obtained.

[0042] D: the polyimide fiber that the surface that step C obtains contains metal palladium is immersed in the electr...

Embodiment 2

[0044] A: The polyimide fiber was etched in 1 mol / L potassium hydroxide solution at 30° C. for 5 minutes, and the fiber was cleaned with deionized water to obtain a surface-modified polyimide fiber.

[0045] B: Immerse the modified polyimide fiber obtained in step A in a palladium chloride solution with a mass concentration of 0.1g / L at 40°C for ion exchange. The ion exchange time is 20 minutes, and the fiber is cleaned with deionized water , to obtain polyimide fibers with palladium ions on the surface.

[0046] C: Immerse the palladium ion-containing polyimide fiber obtained in step B in a solution of dimethylaminoborane with a concentration of 0.1mol / L at 40°C for chemical reduction. The reduction time is 5 minutes, and the fiber is deionized with deionized water. After cleaning, polyimide fibers with an ultra-thin palladium layer on the surface are obtained.

[0047] D: The polyimide fiber with metal palladium on the surface obtained in step C was immersed in the electrol...

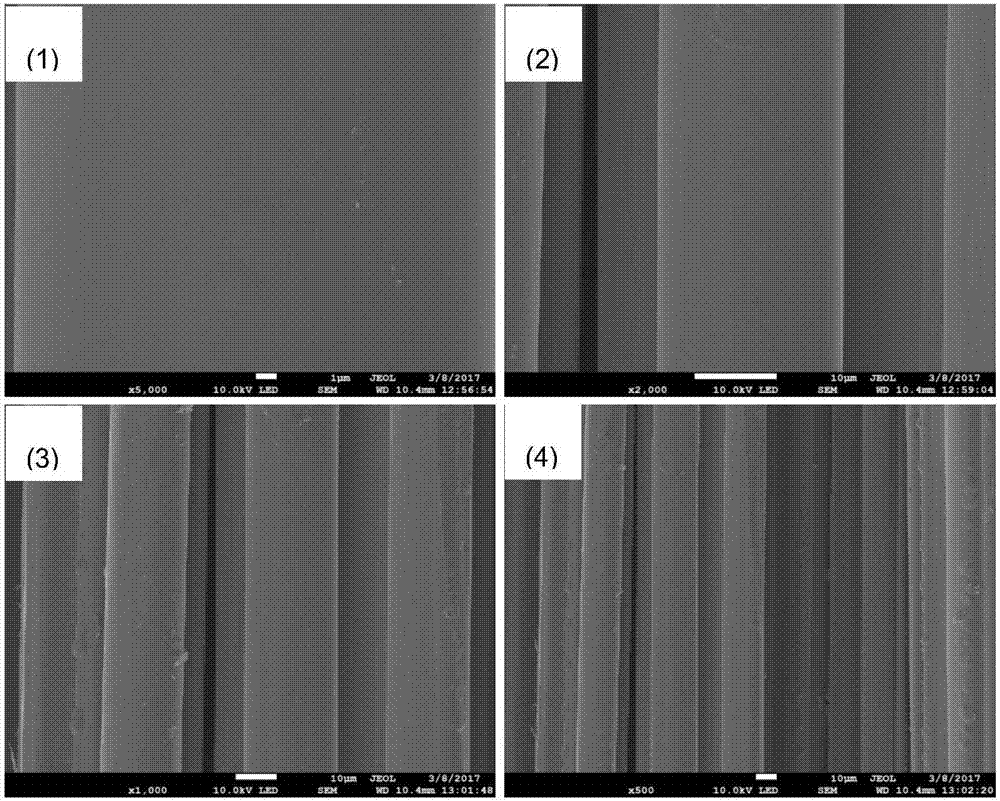

Embodiment 3

[0049] A: The polyimide fiber was etched in 2 mol / L potassium hydroxide solution at 20° C. for 10 min, and the fiber was cleaned with deionized water to obtain a surface-modified polyimide fiber.

[0050] B: Immerse the modified polyimide fiber obtained in step A in a palladium chloride solution with a mass concentration of 0.1g / L at 40°C for ion exchange. The ion exchange time is 10 minutes, and the fiber is cleaned with deionized water , to obtain polyimide fibers with palladium ions on the surface.

[0051] C: Immerse the palladium ion-containing polyimide fiber obtained in step B in a solution of dimethylaminoborane with a concentration of 0.1mol / L at 40°C for chemical reduction. The reduction time is 5 minutes, and the fiber is deionized with deionized water. After cleaning, polyimide fibers with an ultra-thin palladium layer on the surface are obtained.

[0052] D: The polyimide fiber with metal palladium on the surface obtained in step C was immersed in the electroless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com