Nano-structure polypyrrole/biotin composite material based on conductive base material, preparation method and application

A conductive substrate and nanostructure technology, which is applied in the field of preparation of polypyrrole/biotin nanostructures, can solve the problems of easy lodging of nanostructures and complicated methods, and achieve the effects of stable nanostructures, simple methods and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) The specification of sheet-shaped conductive substrate titanium is 10×10×1mm 3 , super-clean the substrate with deionized water, 99.7% absolute ethanol and 99.5% acetone respectively for 20 minutes;

[0036] (2) Select the three-electrode mode, the conductive substrate is the working electrode, the copper sheet is the counter electrode, the saturated calomel electrode is the reference electrode, the concentration of pyrrole in the electrolyte solution is 0.2mol / L, and the concentration of hydrochloric acid is 0.25mol / L , the electrochemical reaction is controlled by chronoamperometry, the reaction potential (relative to the reference electrode) is 0.8V, and the reaction time is 20 seconds. A layer of dense and uniform black polypyrrole is deposited on the titanium electrode, which is soaked in deionized water to Remove the unreacted pyrrole and hydrochloric acid on the surface to obtain a titanium electrode deposited with polypyrrole;

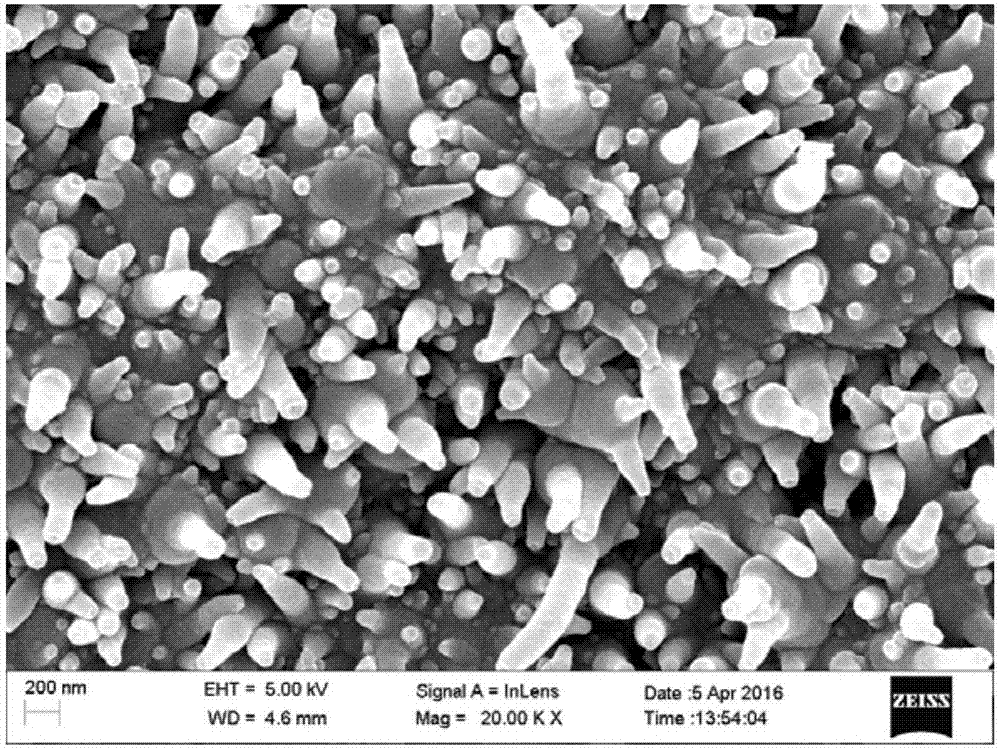

[0037] (3) Select the three-...

Embodiment 2

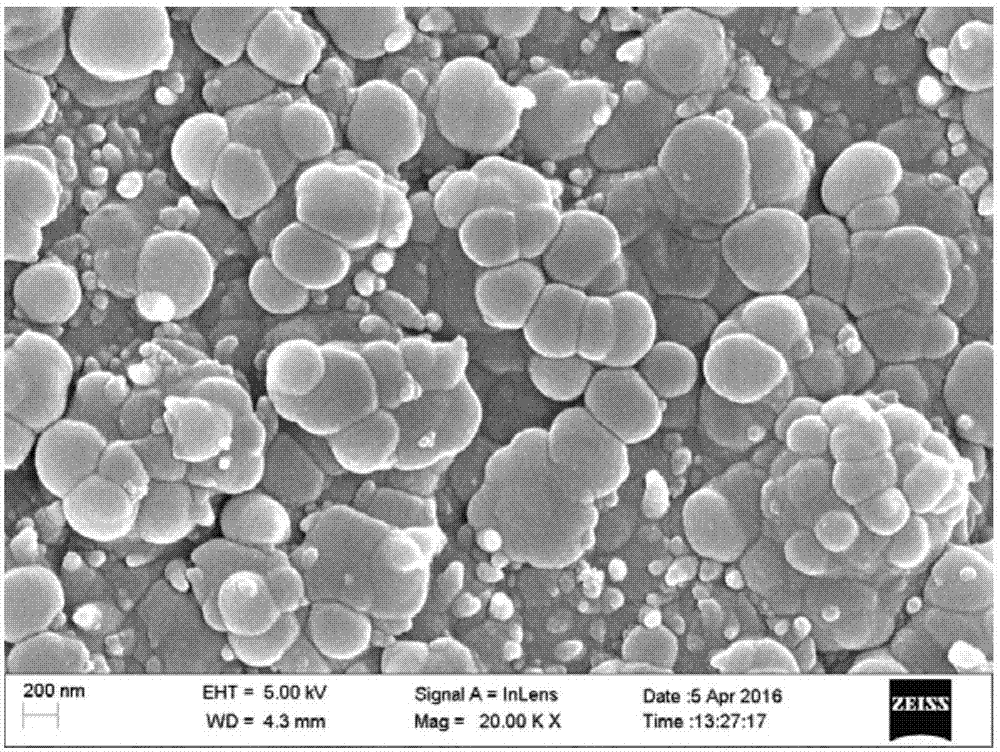

[0040] (1) Sheet conductive substrate (conductive glass) specification is 10×10×1mm 3 , super-clean the substrate with deionized water, 99.7% absolute ethanol and 99.5% acetone respectively for 20 minutes;

[0041] (2) Select the three-electrode mode, the conductive substrate is the working electrode, the copper sheet is the counter electrode, the saturated calomel electrode is the reference electrode, the concentration of pyrrole in the electrolyte solution is 0.2mol / L, and the concentration of hydrochloric acid is 0.25mol / L , the electrochemical reaction is controlled by chronoamperometry, the reaction potential (relative to the reference electrode) is 0.8V, the reaction time is 20 seconds, a layer of dense and uniform black polypyrrole is deposited on the conductive glass electrode, and it is soaked in deionized water To remove unreacted pyrrole and hydrochloric acid on the surface, obtain a conductive glass electrode deposited with polypyrrole;

[0042] (3) Select the thr...

Embodiment 3

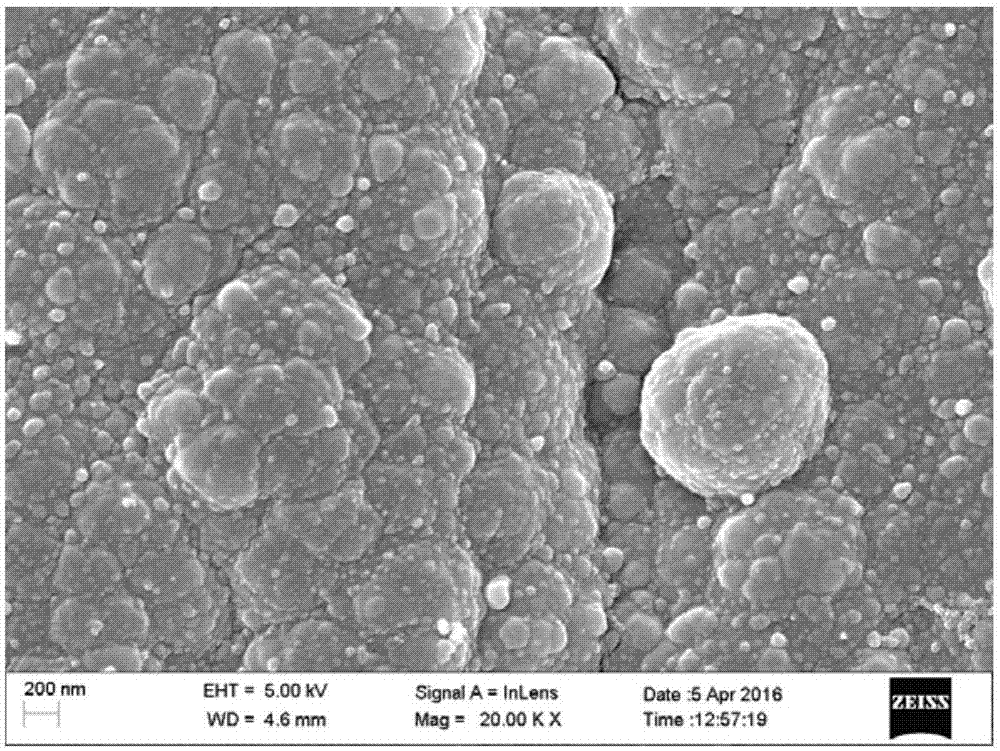

[0045] (1) The specification of sheet-shaped conductive substrate titanium is 10×10×1mm 3 , super-clean the substrate with deionized water, 99.7% absolute ethanol and 99.5% acetone respectively for 20 minutes;

[0046] (2) Select the three-electrode mode, the conductive substrate is the working electrode, the copper sheet is the counter electrode, the saturated calomel electrode is the reference electrode, the concentration of pyrrole in the electrolyte solution is 0.2mol / L, and the concentration of hydrochloric acid is 0.25mol / L , the electrochemical reaction is controlled by chronoamperometry, the reaction potential (relative to the reference electrode) is 0.8V, and the reaction time is 20 seconds. A layer of dense and uniform black polypyrrole is deposited on the titanium electrode, which is soaked in deionized water to Remove the unreacted pyrrole and hydrochloric acid on the surface to obtain a titanium electrode deposited with polypyrrole;

[0047] (3) Select the three-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com