Long-acting waterborne over-rust corrosion protective coating and preparation method thereof

A rust and anti-corrosion, water-based technology, used in anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problems of poor corrosion resistance, poor salt spray resistance, short protection time, etc., to achieve good adhesion and weather resistance, Good flame retardancy and the effect of improving crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0022] A long-acting water-based anti-corrosion coating with rust, which is composed of the following components in parts by weight: 20-35 parts of modified high-performance anti-corrosion emulsion, 10-20 parts of aluminum tripolyphosphate, 6-12 parts of zinc phosphate, disinfectant 0.1-0.8 parts of foaming agent, 2-4 parts of wetting and dispersing agent, 10-20 parts of organic chelating agent dispersion, 37-45 parts of pigment and filler, 0.1-0.2 parts of anti-fungal agent, 0.2-0.3 parts of anti-flash rust agent, 7-12 parts of deionized water.

[0023] The modified high-performance anticorrosion emulsion is one of the DSM Haloflex series.

[0024] The defoamer is at least one of Tego810 and BYK-024.

[0025] The wetting and dispersing agent is at least one of Tego760w, Tego757w, Disponer W-519 and BYK-012.

[0026] The organic chelating agent dispersion is an organic oxime chelating agent dispersion, specifically at least one of the DSM RC series.

[0027] The pigments an...

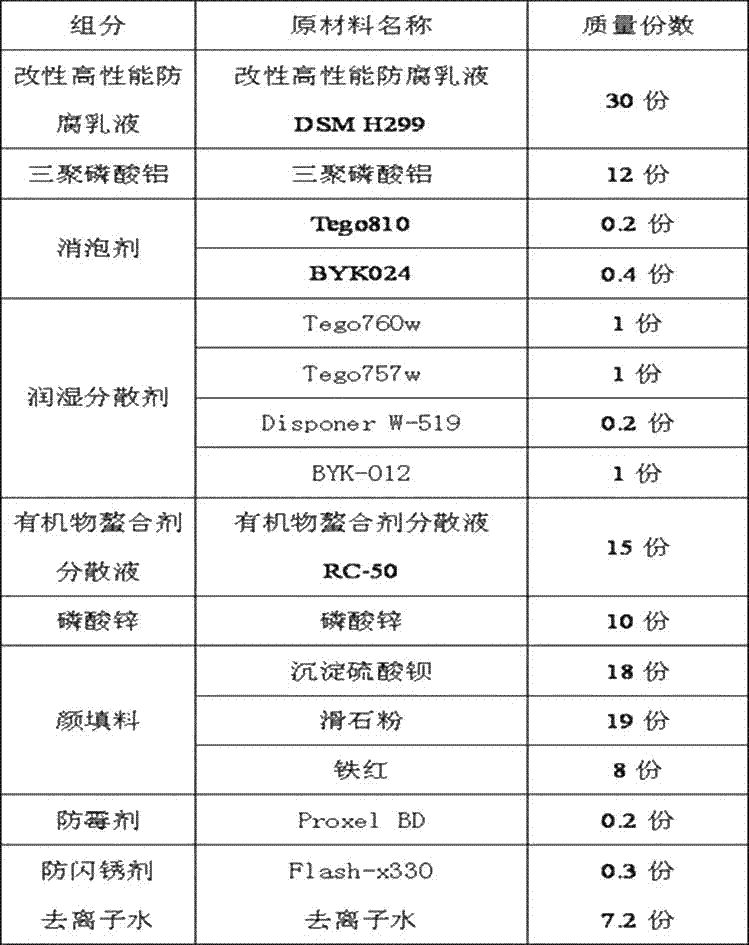

Embodiment 1

[0035] Table 1 is the coating formula of embodiment 1

[0036] Table 1

[0037]

[0038] A kind of preparation method of long-acting water-based anticorrosion coating with rust, comprises the following steps:

[0039]Step 1. According to parts by weight, take 10.3 parts of deionized water, 10 parts of aluminum tripolyphosphate, 12 parts of zinc phosphate, 2.7 parts of defoamer, 0.3 part of anti-flash rust agent, 2 parts of wetting and dispersing agent and organic chelating agent Add 10 parts of the dispersion liquid into the disperser, disperse for 5-10 minutes under the stirring condition of 500-800rpm, and set aside;

[0040] Step 2: Take 37 parts by weight and add 37 parts of pigments and fillers to the mixed material obtained after stirring and dispersing in Step 1, and disperse for 15-25 min under the stirring condition of 1200-1500rpm, and then transfer the obtained material to a grinder Medium grinding until the particle size is 25-40μm, set aside;

[0041] Step 3...

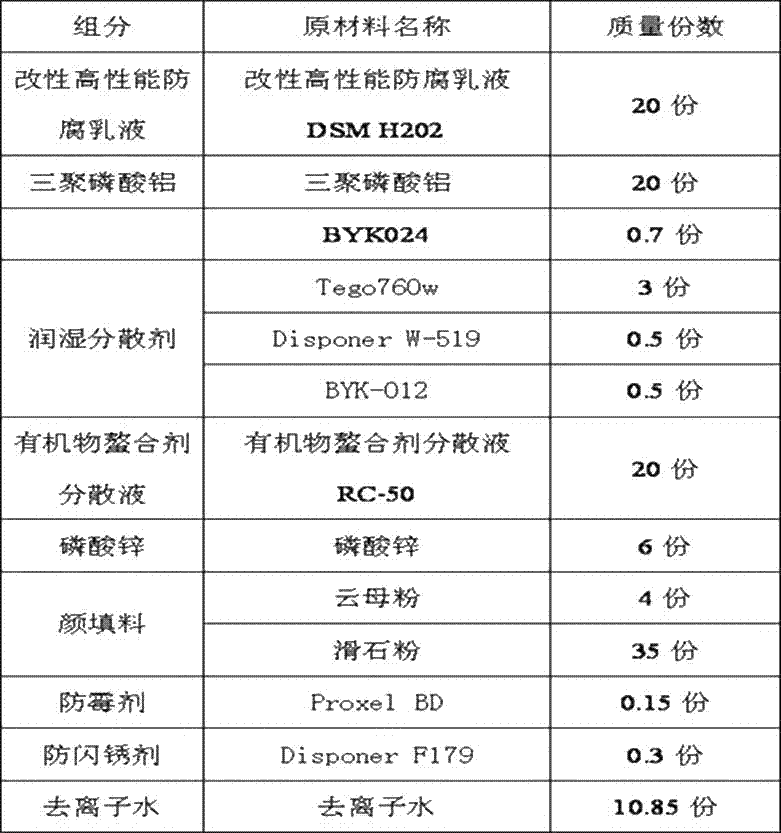

Embodiment 2

[0043] Table 2 is the coating formula of embodiment 2

[0044] Table 2

[0045]

[0046] The preparation method of Example 2 is the same as that of Example 1, except that the specific materials and contents of each component are selected to be modified accordingly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com