Special joint pointing black paint for outer wall imitation brick process and preparation method of black paint

A technology for jointing black paint and imitation brick, applied in the field of paint, can solve the problems of lack of UV resistance and anti-aging function, poor adhesion of the coating film, easy to damage the coating, etc. , to ensure the effect of covering power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

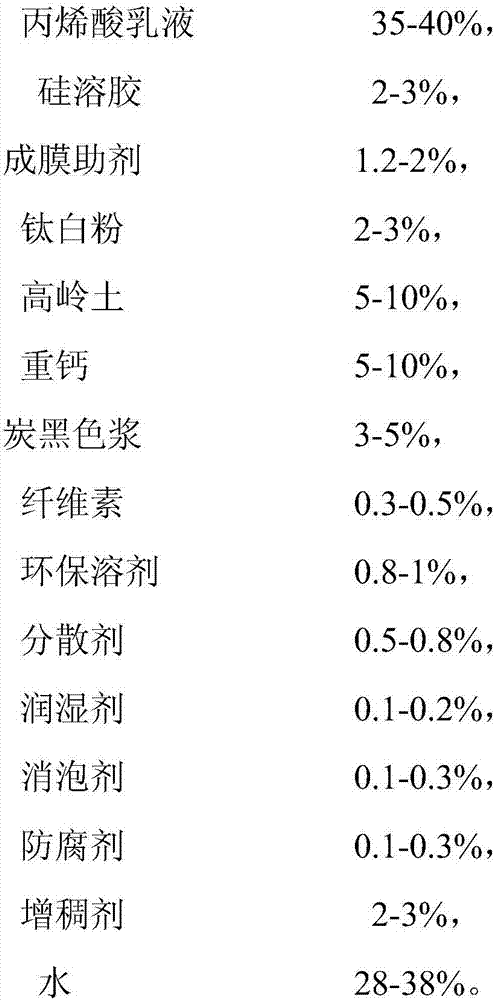

[0029] A special pointing black paint for exterior wall imitation brick process of the present invention is composed of the following components by weight percentage:

[0030]

[0031] The acrylic emulsion is a styrene-acrylic emulsion using AvanseTM emulsion technology, and the minimum film-forming temperature is 29°C.

[0032] The silica sol is a dispersion of nano-colloidal silicon with a small amount of negative charge on the particle surface with a content of 30%, and the particle size of the nano-colloidal silicon dispersion is 14nm.

[0033] The film-forming aid is a 12-carbon compound with a boiling point of 255° C.; the titanium dioxide is a white pigment whose surface is treated with silicon-aluminum coating.

[0034] The kaolin is calcined kaolin with a particle size of 4000 mesh, the heavy calcium is heavy calcium carbonate with a particle size of 800 mesh; the carbon black paste is a water-based black color paste with a concentration of 35%.

[0035] The envir...

Embodiment 2

[0045] The difference between embodiment 2 and embodiment 1:

[0046] A special pointing black paint for exterior wall imitation brick process of the present invention is composed of the following components by weight percentage:

[0047]

[0048] The environmental protection co-solvent is ethylene glycol; the defoamer is mineral oil; and the water is ground water.

[0049] The preparation method of special pointing black paint for exterior wall imitation brick process of the present invention comprises the steps:

[0050] (1) First add accurately weighed water into a tank or a large tank, slowly add cellulose at a low speed of 500r / min, and then add environmental solvents, dispersants, wetting agents, and defoamers in sequence and preservatives, stir for 1.2 minutes after adding, increase the speed to 700r / min at medium speed;

[0051] (2) Add titanium dioxide, kaolin and heavy calcium in turn, increase the speed to 1200r / min, disperse at high speed for 30-40min, finenes...

Embodiment 3

[0054] The difference between embodiment 3 and embodiment 1 is:

[0055] A special pointing black paint for exterior wall imitation brick process of the present invention is composed of the following components by weight percentage:

[0056]

[0057] Described environmental protection co-solvent is the combination of two kinds in propylene glycol or ethylene glycol;

[0058] The preparation method of special pointing black paint for exterior wall imitation brick process of the present invention comprises the steps:

[0059] (1) First add accurately weighed water into a tank or a large tank, slowly add cellulose at a low speed of 600r / min, then add environmental solvents, dispersants, wetting agents, and defoamers in sequence and preservatives, stir for 2 minutes after adding, increase the speed to 800r / min at medium speed;

[0060] (2) Add titanium dioxide, kaolin and heavy calcium in sequence, increase the speed to 1000-1200r / min, disperse at high speed for 30 minutes, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com