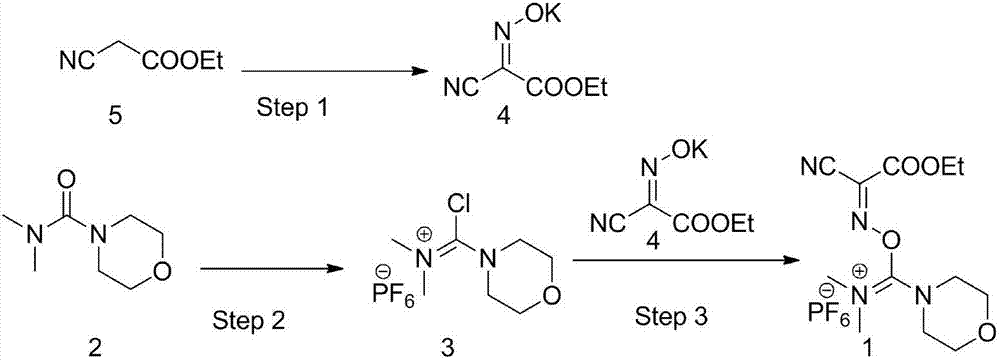

Synthesis process of polypeptide condensation reagent COMU

A technology of condensation reagent and synthesis process, which is applied in the field of synthesis technology of the third-generation polypeptide condensation reagent COMU, can solve the problems of unsuitability for large-scale industrial production, long reaction time, complicated post-processing, etc. Short reaction time and good quality of pure product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A synthetic process for the polypeptide condensation reagent COMU, which uses ethyl cyanoacetate and N,N-dimethylmorpholine-4-carboxamide as raw materials, and includes the following steps:

[0032] (1) Preparation of 2-oxime ethyl cyanoacetate potassium salt

[0033] a. Add ethyl cyanoacetate (30g), water (90mL), and sodium nitrite (19.2g) into a 250mL three-necked flask. After stirring, add 62.5% sulfuric acid aqueous solution (22.9g) dropwise at 35℃. , Adjust the pH to 3, continue to control the temperature after 30 minutes of dripping, and stir for 30 minutes at 35°C. TLC monitors that the reaction is complete, then stop heating, continue stirring for 2 hours, while cooling the reaction solution to a temperature below 15°C, when the temperature of the reaction solution is below 15°C, a large amount of solids precipitate out, filter, and filter the cake with water (wash two Wash each time with 10 mL of water each time) and then wash with petroleum ether (wash twice, 15 m...

Embodiment 2

[0041] A synthetic process for the polypeptide condensation reagent COMU, which uses ethyl cyanoacetate and N,N-dimethylmorpholine-4-carboxamide as raw materials, and includes the following steps:

[0042] (1) Preparation of 2-oxime ethyl cyanoacetate potassium salt

[0043] a. Add ethyl cyanoacetate (1Kg), water (3L), and sodium nitrite (640g) into a 10L three-necked flask. After stirring, add 62.5% sulfuric acid aqueous solution (764g) dropwise at 30℃ and adjust The pH value is 4, after 1h dripping, continue to control the temperature and stir the reaction at 30℃ for 35min. TLC monitors that the reaction is complete, then stop heating, continue to stir for 2h, while cooling the temperature of the reaction liquid to below 15°C, when the temperature of the reaction liquid is below 15°C, a large amount of solids precipitate out, filter, filter cake with water ( Wash twice, with 300mL water each time) and petroleum ether (wash twice, 500mL petroleum ether each time) successively, an...

Embodiment 3

[0051] A synthetic process for the polypeptide condensation reagent COMU, which uses ethyl cyanoacetate and N,N-dimethylmorpholine-4-carboxamide as raw materials, and includes the following steps:

[0052] (1) Preparation of 2-oxime ethyl cyanoacetate potassium salt

[0053] a. Add ethyl cyanoacetate (1000kg), water (3000L), and sodium nitrite (640kg) into the reaction vessel, stir evenly, and add 62.5% acetic acid aqueous solution (22.9kg) dropwise at 40℃, adjust The pH value is 3.5. After the dropping, the temperature is controlled and the reaction is stirred at 40°C for 25 minutes. TLC monitors that the reaction is complete, then stop heating, continue stirring for 2 hours, while cooling the reaction solution to a temperature below 15°C, when the temperature of the reaction solution is below 15°C, a large amount of solids precipitate out, filter, and filter the cake with water (wash two Wash each time with 300L of water each time) and then wash with petroleum ether (wash twice,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com