Preparation method of graphene modified tungsten carbide self-lubrication antiwear additive

A graphene modification and wear-resistant additive technology, applied in the direction of graphene, carbide, tungsten/molybdenum carbide, etc., can solve the problem that it is difficult to ensure the self-lubricating and wear-resistant properties of the prepared coating, and it is difficult to uniformly mix the spray powder. Graphene has a large specific surface area and other problems, and achieves the effect of retaining the content and uniform distribution of components, reducing friction coefficient and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

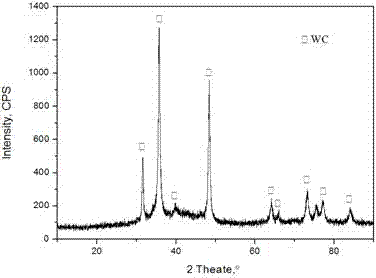

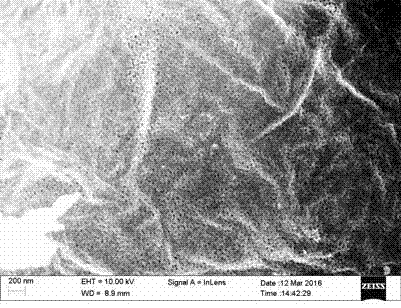

Image

Examples

Embodiment 1

[0026] The invention provides a graphene-modified tungsten carbide self-lubricating wear-resistant additive. The preparation process is as follows: a certain amount of graphite powder is added to a solution composed of concentrated H2SO4 (12mL), K2S2O8 (2.5g) and P2O5 (2.5g) , reacted at 80°C for 4.5 hours. After cooling to room temperature, 0.5 L of deionized water was added. and dry at room temperature. Add this pre-oxidized graphite powder to 150mL of concentrated H2SO4, keep the environment at 0°C with an ice-water bath, gradually add 15g KMnO4, and keep the temperature not exceeding 20°C, and stir at 35°C for 2 hours after the addition. Then 250 mL of deionized water was added and stirred for 2 hours. Then add 0.7 L of deionized water, then add 30 mL of 30% H2O2, dry at room temperature, and then dialyze in a dialysis bag for 1 week to remove heteroions. Finally, it was vacuum filtered and dried at room temperature to obtain graphene oxide.

[0027] Weigh 1g of graphe...

Embodiment 2

[0038] On the basis of the foregoing embodiments, the present embodiment provides a preparation process of a graphene-modified tungsten carbide self-lubricating wear-resistant additive as follows: a certain amount of graphite powder is added to concentrated H2SO4 (12mL), K2S2O8 (2.5g) and In a solution composed of P2O5 (2.5g), react at 80°C for 4.5 hours. After cooling to room temperature, 0.5 L of deionized water was added. and dry at room temperature. Add this pre-oxidized graphite powder to 150mL of concentrated H2SO4, keep the environment at 0°C with an ice-water bath, gradually add 15g KMnO4, and keep the temperature not exceeding 20°C, and stir at 35°C for 2 hours after the addition. Then 250 mL of deionized water was added and stirred for 2 hours. Then add 0.7 L of deionized water, then add 30 mL of 30% H2O2, dry at room temperature, and then dialyze in a dialysis bag for 1 week to remove heteroions. Finally, it was vacuum filtered and dried at room temperature to ob...

Embodiment 3

[0046] On the basis of the foregoing embodiments, the present embodiment provides a preparation process of a graphene-modified tungsten carbide self-lubricating wear-resistant additive as follows: a certain amount of graphite powder is added to concentrated H2SO4 (12mL), K2S2O8 (2.5g) and In a solution composed of P2O5 (2.5g), react at 80°C for 4.5 hours. After cooling to room temperature, 0.5 L of deionized water was added. and dry at room temperature. Add this pre-oxidized graphite powder to 150mL of concentrated H2SO4, keep the environment at 0°C with an ice-water bath, gradually add 15g KMnO4, and keep the temperature not exceeding 20°C, and stir at 35°C for 2 hours after the addition. Then 250 mL of deionized water was added and stirred for 2 hours. Then add 0.7 L of deionized water, then add 30 mL of 30% H2O2, dry at room temperature, and then dialyze in a dialysis bag for 1 week to remove heteroions. Finally, it was vacuum filtered and dried at room temperature to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear loss | aaaaa | aaaaa |

| Wear loss | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com