Preparation method and application of molecular sieve photocatalyst for vocs degradation

A technology of photocatalyst and molecular sieve, which is applied in the field of preparation of molecular sieve photocatalyst, can solve the problems of increasing carbon emissions, poor selective adsorption, and low conversion rate of exhaust gas, and achieve the effect of reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

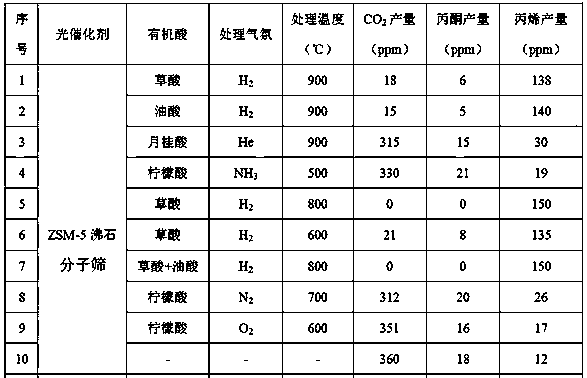

Image

Examples

Embodiment 1

[0024] 1. Oxalic acid treatment ZSM-5

[0025] Weigh 3.2 g of C with an electronic balance 2 h 2 o 4 2H 2 O solid was dissolved with deionized water, then transferred to a 100 mL volumetric flask, washed, and constant volume to obtain a 0.25 mol / L oxalic acid solution; at room temperature, 7 g ZSM-5 zeolite molecular sieves were added to the oxalic acid solution, Stir and react for 10 h; then centrifuge, wash with water, filter with suction, and dry to obtain a molecular sieve catalyst treated with oxalic acid.

[0026] , ZSM-5 in H 2 High temperature calcination treatment under atmosphere

[0027] Place the above-mentioned oxalic acid-treated molecular sieve catalyst in a high-temperature tube furnace, and feed H at a rate of 150 ml / min. 2 , ventilate at room temperature for 30 min to remove the air in the tube, then raise the temperature to 900 °C at a rate of 5 °C / min and keep it for 10 h, and turn off the H2 when the temperature drops to 400 °C 2 , purged with nitro...

Embodiment 2

[0034] The specific ZSM-5 treatment method is basically the same as in Example 1 of this part, except that oxalic acid is changed to oleic acid, and the stirring reaction time is changed from 10 hours to 1 hour.

Embodiment 3

[0036] Concrete ZSM-5 processing method is basically the same as this part embodiment 1, and difference is that oxalic acid is changed into lauric acid, and H 2 Change to He.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com