Titanium dioxide-based catalyst, and preparation method and application thereof

A titanium dioxide and catalyst technology, applied in the field of titanium dioxide-based catalysts and their preparation, can solve the problems of molecular sieve skeleton collapse, catalyst activity decline, dealumination, etc., and achieve the effects of increasing surface oxygen holes, promoting uniform dispersion, and high nitrogen selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

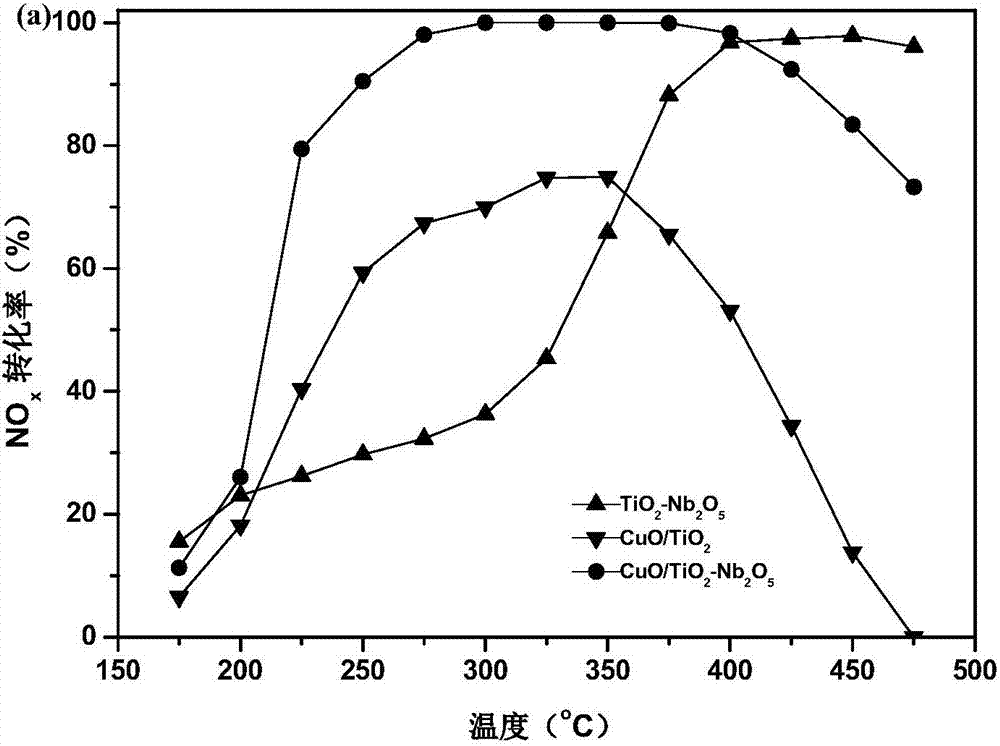

[0051] Example 1: CuO / TiO 2 -Nb 2 o 5 Catalyst preparation

[0052] Weigh 0.17g sodium dodecylbenzenesulfonate and dissolve it in 100mL ultrapure water, then add 1.72g TiOSO in the mixed solution 4 · x H 2 SO 4 · x H 2 O (titanyl sulfate, molecular weight 159.95), stirred and mixed. Weigh 2.70g NbCl 5 (Molecular weight is 270.17), join in 50mL ultrapure water. The two solutions were mixed and stirred for 30 min. Weigh 9.01 g of urea and dissolve it in 100 mL of ultrapure water to prepare an aqueous urea solution. The urea aqueous solution was added dropwise to the above mixed solution for stirring, and the temperature was raised to 85° C., and reacted for 3 hours. After the reaction, the mixed solution was cooled to normal temperature at room temperature of 25° C., the supernatant was discarded, and the turbid solution was centrifuged to obtain a white precipitate. Wash the white precipitate 4 times with ultrapure water, AgNO 3 solution and BaCl 4 Solution detecti...

Embodiment 2

[0054] Example 2: CuO / TiO 2 -Nb 2 o 5 Catalyst preparation

[0055] Weigh 0.17g sodium dodecylbenzenesulfonate and dissolve it in 100mL ultrapure water, then add 1.72g TiOSO in the mixed solution 4 · x H 2 SO 4 · x H 2 O (titanyl sulfate, molecular weight 159.95), stirred and mixed. Weigh 2.70g NbCl 5 (Molecular weight is 270.17), join in 50mL ultrapure water. The two solutions were mixed and stirred for 30 min. Weigh 9.01 g of urea and dissolve it in 100 mL of ultrapure water to prepare an aqueous urea solution. The urea solution was added dropwise to the above mixed solution for stirring, and the temperature was raised to 80° C., and reacted for 3 hours. After the reaction, the mixed solution was cooled to normal temperature at room temperature of 25° C., the supernatant was discarded, and the turbid solution was centrifuged to obtain a white precipitate. Wash the white precipitate 3 times with ultrapure water, AgNO 3 solution and BaCl 4 Solution detection wash ...

Embodiment 3

[0057] Example 3: CuO / TiO 2 -Nb 2 o 5 Catalyst preparation

[0058] Weigh 0.17g sodium dodecylbenzenesulfonate and dissolve it in 100mL ultrapure water, then add 1.72g TiOSO in the mixed solution 4 · x H 2 SO 4 · x H 2 O (titanyl sulfate, molecular weight 159.95), stirred and mixed. Weigh 2.70g NbCl 5 (Molecular weight is 270.17), join in 50mL ultrapure water. The two solutions were mixed and stirred for 30 min. Weigh 9.01 g of urea and dissolve it in 100 mL of ultrapure water to prepare an aqueous urea solution. The urea solution was added dropwise to the above mixed solution for stirring, and the temperature was raised to 100° C., and reacted for 3 hours. After the reaction, the mixed solution was cooled to normal temperature at room temperature of 25° C., the supernatant was discarded, and the turbid solution was centrifuged to obtain a white precipitate. Wash the white precipitate 5 times with ultrapure water, AgNO 3 solution and BaCl 4 Solution detection wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com