Method for vinyl chloride synthesis waste treatment and control

A technology of waste treatment and control method, applied in combustion product treatment, separation method, gas treatment and other directions, can solve problems such as affecting the absorption of falling film absorbers, affecting quality, polluting hydrochloric acid, etc., to meet environmental protection requirements and save operating costs , the effect of reducing poison

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

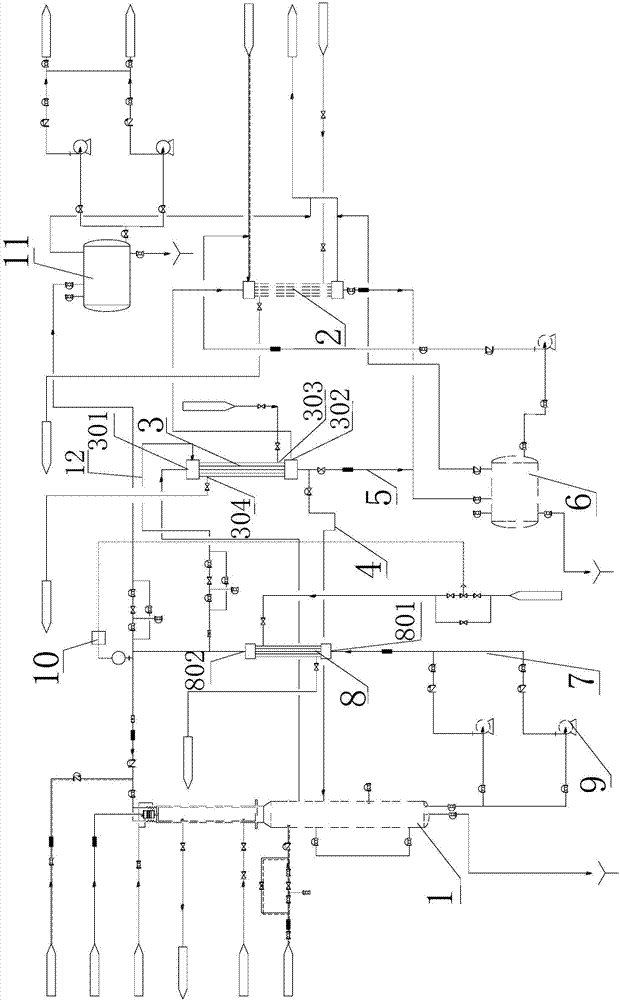

[0030] Such as figure 1 As shown, this embodiment provides a waste treatment device for vinyl chloride synthesis, including an incineration device, a quenching device 1 and a falling film absorption device 2. The incineration device incinerates waste to generate flue gas, and the flue gas passes through the quenching device 1 and enters the falling film absorption device. absorption in the device 2, and a cooling device 3 is provided between the quenching device 1 and the falling film absorption device 2.

[0031] At present, the waste produced after the synthesis of vinyl chloride is burned in the incineration device at a temperature above 1100°C to produce water vapor, carbon dioxide, hydrogen chloride, and a small amount of nitrogen oxides and chlorine gas. After passing through the waste heat device, the temperature drops to about 550°C. The quenching tower cools down, and at the same time, part of the hydrogen chloride gas and water vapor in the flue gas are absorbed by t...

Embodiment 2

[0048] Such as figure 1 As shown, the present embodiment is a further limitation of embodiment one. The quenching device 1 of the present embodiment is a quenching tower, and the quenching tower is provided with an acid liquid circulation line 7 for cooling the flue gas of combustion products, and the acid liquid circulation line One end of 7 is connected with the bottom of the quenching tower, and the other end is connected with the top of the quenching tower.

[0049] The general quenching tower cools the flue gas tail gas produced by the incinerator by adding water, so it cannot ensure that the amount of water matches the amount of hydrogen chloride in the flue gas, so only low-concentration hydrochloric acid can be produced, and its concentration is lower than 15%. The quench tower in this embodiment is provided with an acid liquid circulation pipeline 7 for cooling the flue gas of combustion products. The acid liquid circulation line 7 is provided with a circulation pump...

Embodiment 3

[0064] This embodiment is a further limitation of Embodiment 1 and Embodiment 2. This embodiment provides a waste treatment control method for vinyl chloride synthesis, which includes the following steps:

[0065] (1) Incineration: Incineration of waste after vinyl chloride synthesis produces high-temperature flue gas;

[0066] (2) Quenching: high-temperature flue gas enters the quenching tower and contacts with circulating acid liquid to cool down;

[0067] (3) Condensation: the cooled flue gas enters the condenser to cool down again;

[0068] (4) Absorption: The flue gas after cooling down again enters the falling film absorber for absorption, and the tail gas after absorption enters the alkali washing tower for treatment.

[0069] In step (1), the temperature of the high-temperature flue gas generated by incineration of waste is 1100°C-1200°C; the high-temperature flue gas passes through the waste heat furnace for heat exchange, and the temperature drops to 550°C-600°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com