Method for preparing high-activity ginsenoside by solid dynamic fermentation technology

A ginsenoside, dynamic fermentation technology, applied in the field of ginsenoside, can solve the problems of cumbersome process, low conversion rate of low-glycosyl saponin, complicated operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Preparation of fermented bacteria seeds: Take 300g of ginseng root and crush it to 10-20 mesh, mix it with 900g of wheat bran, add 1L of water, stir evenly, put it into a triangular flask, sterilize at 120°C for 20 minutes, and put it into the research team for screening after cooling down A kind of Aspergillus niger, which was produced, was cultured at 28°C for 7-8 days to obtain fermented seeds.

[0062] Large-scale fermentation: Take 50kg of ginseng root, crush it to 10-20 mesh, mix it with 50kg of wheat bran, 20kg of soybean meal, and 80kg of water, put it into the fermentation tank, stir evenly, steam heat to 100°C for sterilization, and cool it down rapidly after 10 minutes to 40°C, and then insert the prepared seeds. The fermenter is always fed with filtered sterile air, the temperature of the interlayer of the fermenter is set at 30°C, and after 30 hours of heat preservation, the product temperature is kept between 28-30°C. After 10 days of fermentation, the fe...

Embodiment 2

[0064] Fermented seeds were prepared according to the method in Example 1.

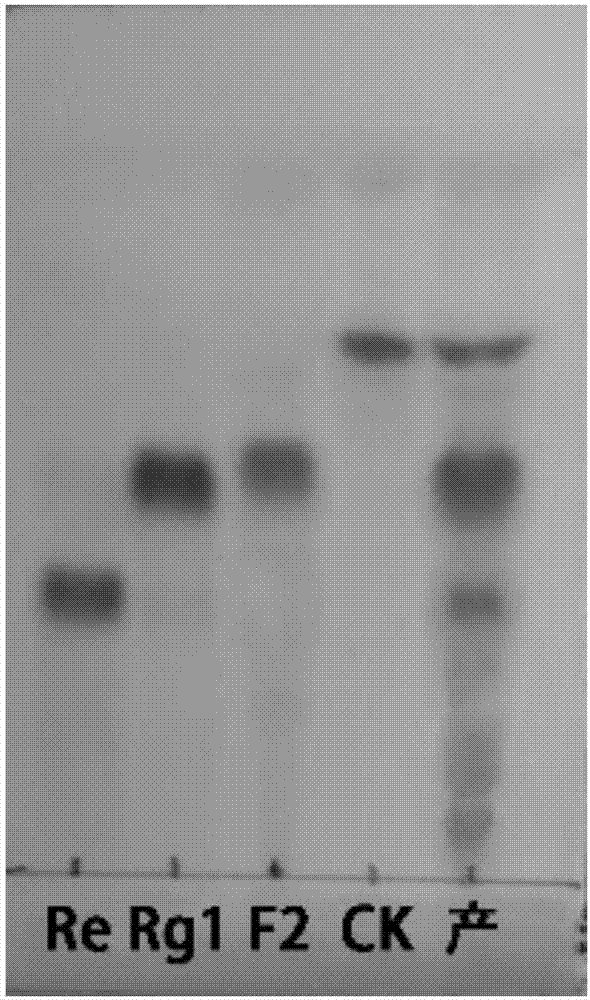

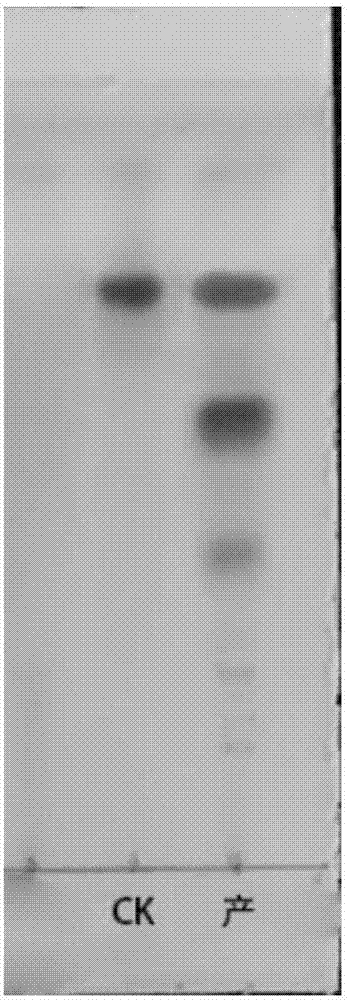

[0065] Take 30kg of ginseng root, crush it to 10-20 mesh, mix it with 70kg of wheat bran, 20kg of Sophora japonica flower, and 70kg of water, put it into a fermenter, stir evenly, steam heat to 100°C for sterilization, and after 10 minutes, rapidly cool to 40°C ℃, and then insert the prepared seeds. The fermenter is always fed with filtered sterile air, the temperature of the interlayer of the fermenter is set at 30°C, and after 30 hours of heat preservation, the product temperature is kept between 28-30°C. After 12 days of fermentation, the fermentation product is rich in F2 and CK, such as figure 2 shown.

[0066] Then add 500L methanol to the fermenter, extract 3 times at 50°C for 3 hours each time, concentrate the extract under reduced pressure at 25~70°C and -0.01Mpa~1Mpa until no methanol remains, add 50L cyclohexane to degrease twice, Put the degreased solution on a 30LAB-8 macroporous adso...

Embodiment 3

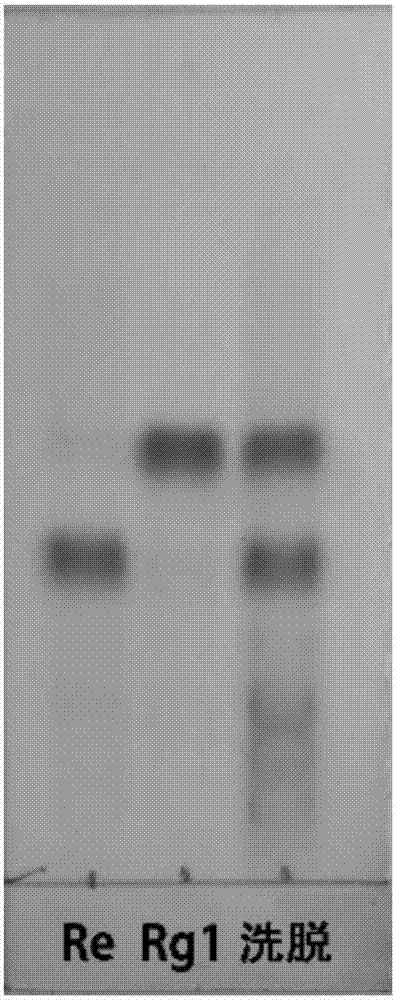

[0068]In Example 2, 116 kg of the slag soaked in methanol was extracted, and 400 L of water was added to it, and the ginsenoside hydrolase was extracted at 70° C. for 6 hours, extracted twice, and the extracts were combined, concentrated at 55° C. to reach 52 Brix, and 11.8 kg of active ginseng was obtained. Hydrolase solution. Get F2 10g obtained in Example 2, dissolve in 200mL water, add 20mL acetic acid, mix with 200g active ginseng hydrolase solution, react at 80°C for 4h, add 800mL deionized water, the product is Rh2 group saponin, i.e. 20( R)-Rh2, 20(S)-Rh2, Rk2 and Rh3, and saponins. Extracted 3 times with water-saturated n-butanol, combined the n-butanol layers, evaporated to dryness to obtain 5.8g of powder, and the TLC detection results were as follows: Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com