Manufacturing method for target material assembly

A manufacturing method and component technology, applied in the field of target component manufacturing, can solve the problems of low yield rate of sputtering targets, achieve the effect of improving welding strength, improving yield rate, and avoiding adverse effects on quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

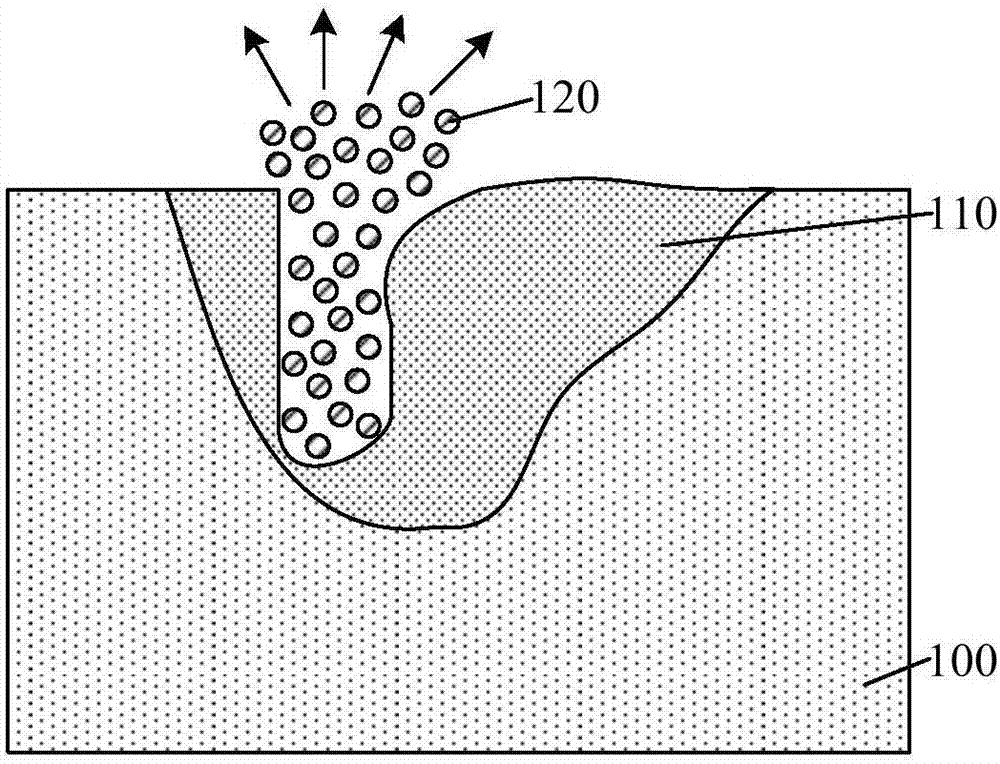

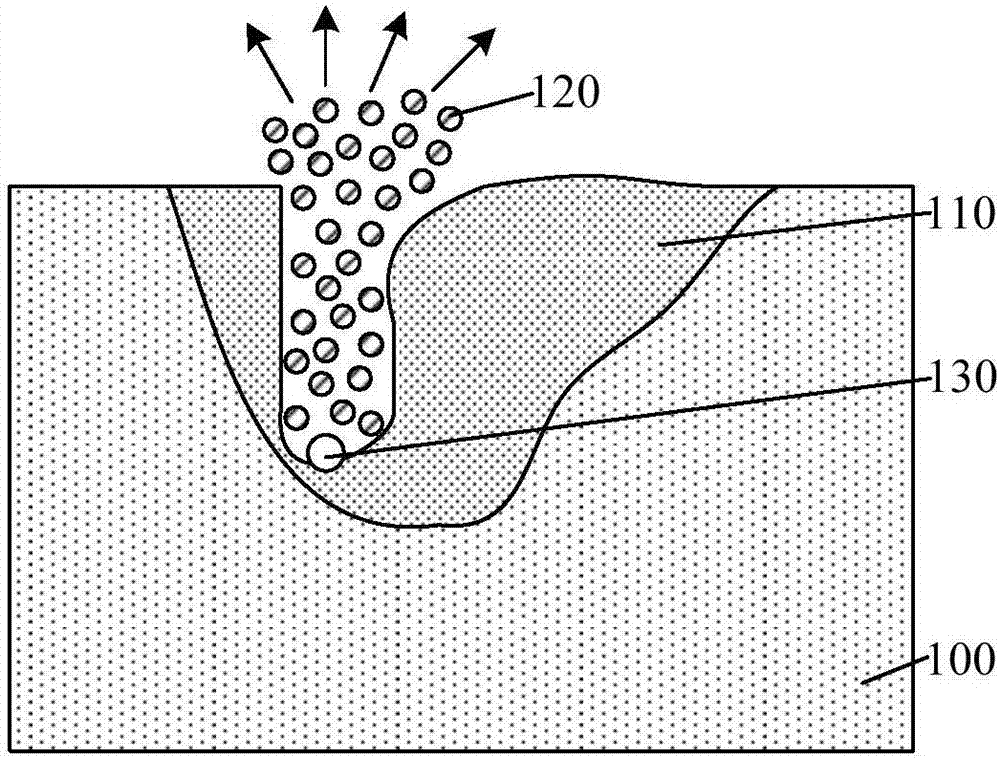

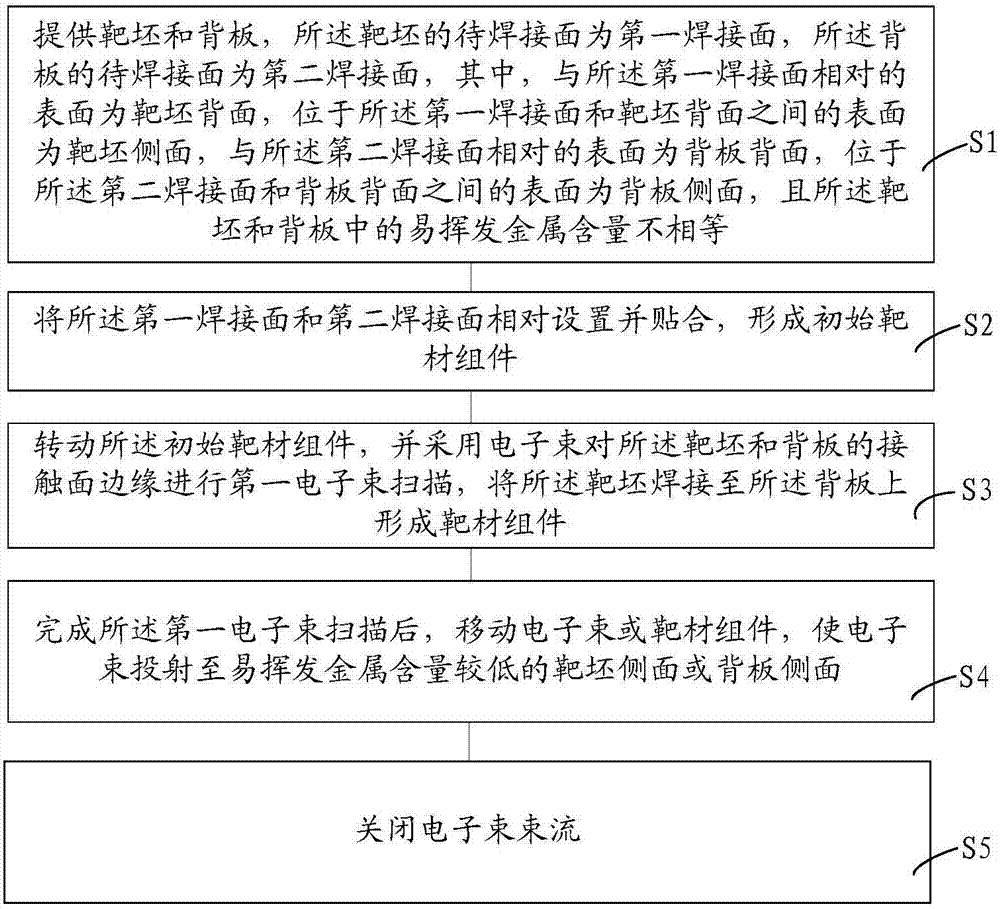

[0022] It can be seen from the background art that the yield rate of the sputtering target formed by electron beam welding in the prior art is low. combined reference figure 1 with figure 2 , shows a schematic diagram of the principle of an embodiment of electron beam welding, and the reason for the analysis is:

[0023] In the first aluminum alloy 100 that will contain more volatile metals 120 (such as figure 1 shown) and the second aluminum alloy (not shown) that does not contain volatile metals for electron beam welding, the directional high-speed and focused electron beam bombards the first aluminum alloy 100 and the second aluminum alloy to convert kinetic energy into Thermal energy melts the first aluminum alloy 100 and the second aluminum alloy at a partial depth of the weld, and forms a molten pool 110 in the first aluminum alloy 100; as the temperature increases, the first aluminum alloy The volatile metal 120 in the alloy 100 is prone to volatilization, and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com