A kind of ptc type heater processing method

A processing method and heater technology, applied in the direction of the shape of the heating element, etc., can solve the problems of difficulty in ensuring the vertical arrangement of PTC heat-sensitive ceramic sheets, dumping of PTC heat-sensitive ceramic sheets, and difficulty in controlling the interval of artificial sheet arrangement, etc., to achieve improved sheet arrangement Efficiency, preventing precipitation, and ensuring the effect of heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

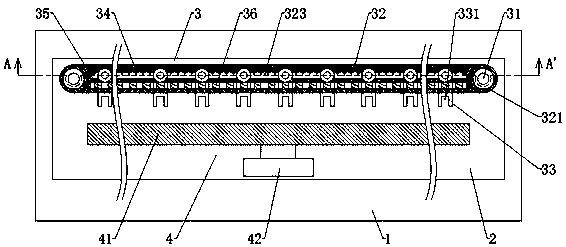

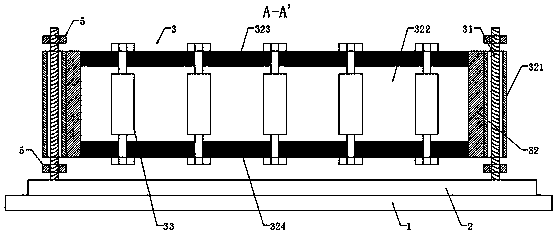

Image

Examples

Embodiment 1

[0037] A method for processing a PTC type heater, the specific steps are:

[0038]1) Preparation of PTC heat-sensitive ceramic tablets: first put the raw materials into a grinding mill, grind and stir for 8 hours; then put the pulverized and stirred mixture into an airflow granulator, and place the granulated particles In the molding machine, it is pressed into a sheet; then the PTC heat-sensitive ceramic sheet pressed into a sheet is sintered in a kiln, and after the sintering is completed, it is cooled by high-pressure air blowing with pure nitrogen; Grinding and chamfering with a chamfering machine; finally, cleaning and drying the PTC heat-sensitive ceramic heating element for later use;

[0039] Wherein, the composition of raw material and the parts by weight of each composition are respectively: BaCO 3 60 parts, SrCO 3 11 copies, Y 2 o 3 0.5 parts, SiO 2 0.3 parts, TiO 2 40 parts BaTiO 3 25 copies;

[0040] High-pressure air blow cooling is divided into 5 bl...

Embodiment 2

[0051] A method for processing a PTC type heater, the specific steps are:

[0052] 1) Preparation of PTC heat-sensitive ceramic tablets: first put the raw materials into a grinding mill, grind and stir for 12 hours; then put the pulverized and stirred mixture into an airflow granulator, and place the granulated particles In the forming machine, pressed into flakes; then pressed into flakes of PTC60 parts, SrCO 3 11 copies, Y 2 o 3 0.5 parts, SiO 2 0.3 parts, TiO 2 40 parts BaTiO 3 25 copies;

[0053] High-pressure air blow cooling is divided into 5 blows, each time 1s, the more blows, the shorter the time of each blow;

[0054] 2) Adhesive glue preparation: heat up the adhesive collagen solution to 55°C at a rate of 8°C / min, and stir for 15 minutes; then filter the stirred adhesive collagen solution, and keep the adhesive collagen solution at 55°C during the filtration period. Until there is no precipitation in the adhesive collagen solution; finally, continue to ke...

Embodiment 3

[0064] A method for processing a PTC type heater, the specific steps are:

[0065] 1) Preparation of PTC heat-sensitive ceramic tablets: first put the raw materials into a grinding mill, grind and stir for 10 hours; then put the pulverized and stirred mixture into an airflow granulator, and place the granulated particles In the molding machine, it is pressed into a sheet; then the PTC heat-sensitive ceramic sheet pressed into a sheet is sintered in a kiln, and after the sintering is completed, it is cooled by high-pressure air blowing with pure nitrogen; Grinding and chamfering with a chamfering machine; finally, cleaning and drying the PTC heat-sensitive ceramic heating element for later use;

[0066] Wherein, the composition of raw material and the parts by weight of each composition are respectively: BaCO 3 57 parts, SrCO 3 12 copies, Y 2 o 3 0.4 parts, SiO 2 0.5 parts, TiO 2 38 parts, BaTiO 3 26 copies;

[0067] High-pressure air blow cooling is divided into 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com