A method for detecting high-temperature melting ability of chrome ore and sample components

A technology of melting ability and chromium ore, which is applied in the field of metallurgy, can solve the problems of high melting point of chromium ore, difficulty in obtaining high-temperature melting performance, etc., achieve high stability, sufficient heat transfer, and reduce the difficulty of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Select the chrome ore ore kind as South African chrome ore, Turkey chrome ore, Tibet chrome ore, and the method for detecting the high-temperature melting ability of the chrome ore includes the following steps:

[0042] 1) Finely grind the chromium ore in a ball mill to below 0.074mm, put it in a vacuum drying oven, and dry it at 120°C for 3 hours for later use;

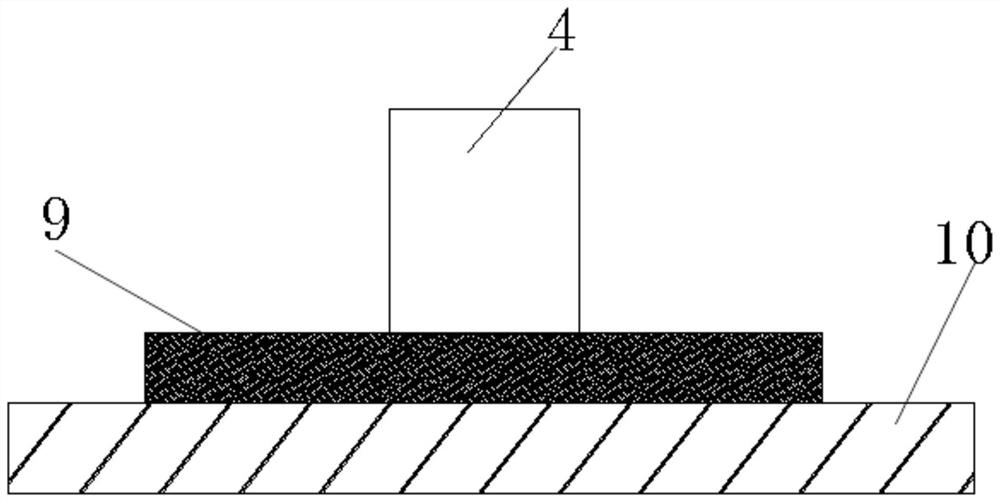

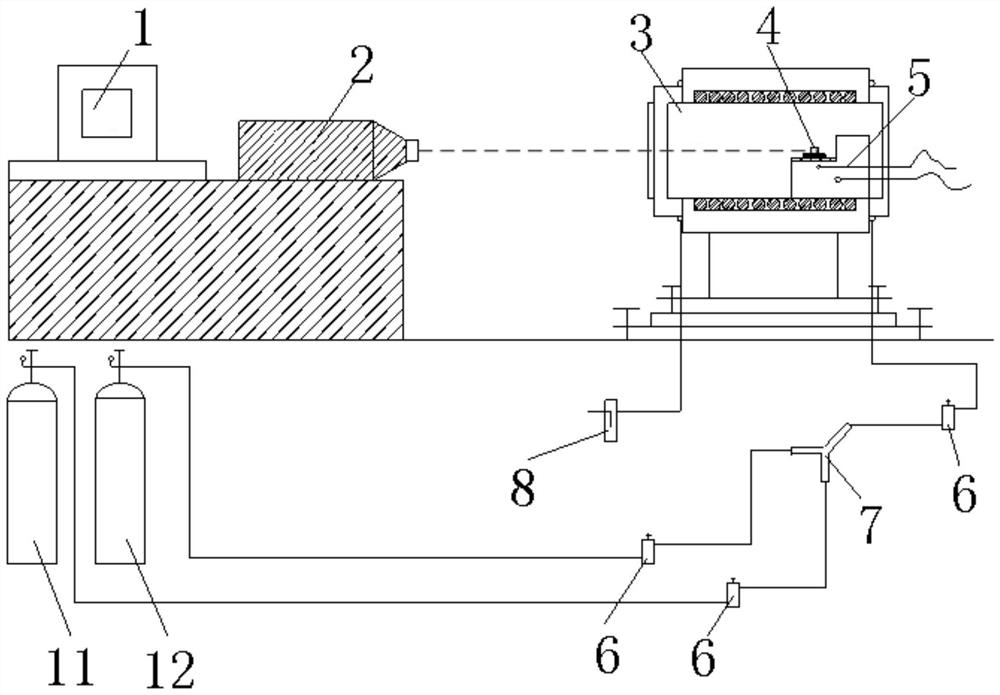

[0043] 2) Take a certain amount of chromium ore powder and press it into a columnar sample with a diameter of 5 mm and a height of 5.5 mm under a pressure of 5 MPa. figure 1 The sample assembly shown is placed in a high temperature furnace;

[0044] 3) Introduce N into the high temperature furnace 2 Mixed gas with CO, in the mixed gas, the content of CO is 85%, and the rest is N 2, the control gas flow rate is 5L / min; the initial heating rate in the high temperature furnace is 20°C / min; the temperature is monitored in real time, when the temperature is 850°C, the heating rate is adjusted to 10°C / min; when th...

Embodiment 2

[0047] Select the chrome ore ore kind as South African chrome ore, Turkey chrome ore, Tibet chrome ore, and the method for detecting the high-temperature melting ability of the chrome ore includes the following steps:

[0048] 1) Finely grind the chromium ore in a ball mill to below 0.074mm, put it in a vacuum drying oven, and dry it at 105°C for 6 hours for later use.

[0049] 2) Take a certain amount of chromium ore powder and press it into a columnar sample with a diameter of 3 mm and a height of 5 mm under a pressure of 4 MPa. figure 1 The sample assembly shown is placed in a high temperature furnace;

[0050] 3) Introduce N into the high temperature furnace 2 Mixed gas with CO, in the mixed gas, the content of CO is 80%, and the rest is N 2 , the control gas flow rate is 5L / min; the initial heating rate in the high temperature furnace is 20°C / min; the temperature is monitored in real time, when the temperature is 850°C, the heating rate is adjusted to 10°C / min; when the...

Embodiment 3

[0053] Select the chrome ore ore kind as South African chrome ore, Turkey chrome ore, Tibet chrome ore, and the method for detecting the high-temperature melting ability of the chrome ore includes the following steps:

[0054] 1) Finely grind the chromium ore in a ball mill to below 0.074mm, put it in a vacuum drying oven, and dry it at 110°C for 4 hours for later use;

[0055] 2) Take a certain amount of chromium ore powder and press it into a columnar sample with a diameter of 6 mm and a height of 8 mm under a pressure of 6 MPa. figure 1 The sample assembly shown is placed in a high temperature furnace;

[0056] 3) Introduce N into the high temperature furnace 2 Mixed gas with CO, in the mixed gas, the content of CO is 90%, and the rest is N 2 , the control gas flow rate is 5L / min; the initial heating rate in the high temperature furnace is 20°C / min; the temperature is monitored in real time, when the temperature is 850°C, the heating rate is adjusted to 10°C / min; when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com