A method of preparing superhydrophobic surface by supersonic flame spraying

A supersonic flame and super-hydrophobic surface technology, which is applied in coating, fusion spraying, metal material coating process, etc., can solve the problem of reduced super-hydrophobic surface structure and performance stability, poor friction resistance, and metal coating surface The structure is easily affected by corrosion, etc., to achieve the effect of large-scale industrial application, good surface hydrophobicity, and high coating preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method utilizing supersonic flame spraying to prepare a superhydrophobic surface, the base material is SMA490BW weathering steel, and the steps are as follows:

[0046] A. Pretreatment of the surface of the substrate: including cleaning and roughening the surface of the substrate. The roughening treatment refers to sandblasting treatment. The sandblasting process parameters are air pressure 0.7MPa, and the sand shot used for sandblasting is 80 mesh brown corundum Sand, sandblasting time 40 seconds;

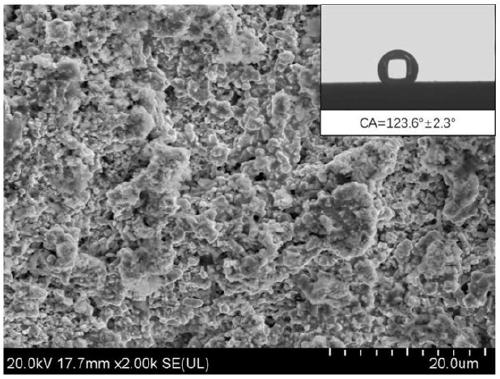

[0047] B, adopt supersonic flame spraying method to prepare tungsten carbide system coating on the substrate surface after pretreatment, described spraying powder is nanometer WC-12Co powder; The flow rate of oxygen is 900L / min, the flow rate of kerosene is 23L / h, and the moving speed of the spray gun is 1.5m / s. A layer of 280-300μm coating is deposited on the surface of the substrate. The coating morphology and droplet contact angle are as follows: figure 1 shown;

[0...

Embodiment 2

[0051] A method utilizing supersonic flame spraying to prepare a superhydrophobic surface, the base material is Q235 steel, and the steps are as follows:

[0052] A. Pretreatment of the surface of the substrate: including cleaning and roughening the surface of the substrate. The roughening treatment refers to sandblasting treatment. The sandblasting process parameters are air pressure 0.7MPa, and the sand shot used for sandblasting is 60 mesh brown corundum Sand, sandblasting time 35 seconds;

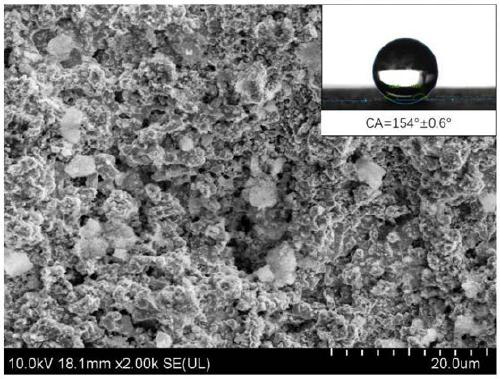

[0053] B. Prepare a tungsten carbide system coating on the surface of the pretreated substrate by supersonic flame spraying method, the spraying powder is nano WC-10Co-4Cr powder; the spraying process parameters are: powder feeding amount 82g / min, spraying distance 350mm, oxygen flow rate 900L / min, kerosene flow rate 23L / h, spray gun moving speed 1.5m / s, deposit a layer of 280-300μm coating on the surface of the substrate;

[0054] C. The surface of the coating of the tungsten carbide ...

Embodiment 3

[0057] A method for preparing a superhydrophobic surface by supersonic flame spraying, the substrate is a metal material, and the steps are as follows:

[0058] A. Pretreatment of the surface of the substrate: including cleaning and roughening the surface of the substrate. The roughening treatment refers to sandblasting treatment. The sandblasting process parameters are air pressure 0.5MPa, and the sand shot used for sandblasting is 120 mesh brown corundum Sand, sandblasting time 60 seconds;

[0059] B. Prepare a tungsten carbide system coating on the surface of the pretreated substrate by supersonic flame spraying method, the spraying powder is nano WC-12Co powder; the spraying process parameters are: powder feeding amount 78g / min, spraying distance 320mm, Oxygen flow 900L / min, kerosene flow 25L / h, spray gun moving speed 1.2m / s;

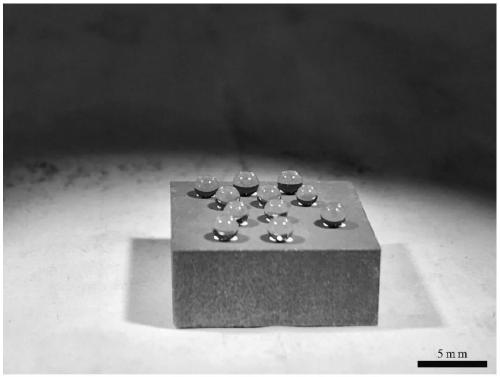

[0060] C. The surface of the coating of the tungsten carbide system prepared in step B is modified with a layer of low surface energy substances t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com