Method for detecting formation of nanocrystals on 690 high-strength steel surfaces

A detection method, high-strength steel technology, applied in the direction of measuring devices, preparation of test samples, material analysis using radiation diffraction, etc., can solve problems such as long inspection period, damage to the surface of the material, and measurement of grain size errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] A detection method for forming nanocrystals on the surface of 690 high-strength steel, comprising the following steps:

[0036] Several pieces of 690 high-strength steel samples were prepared.

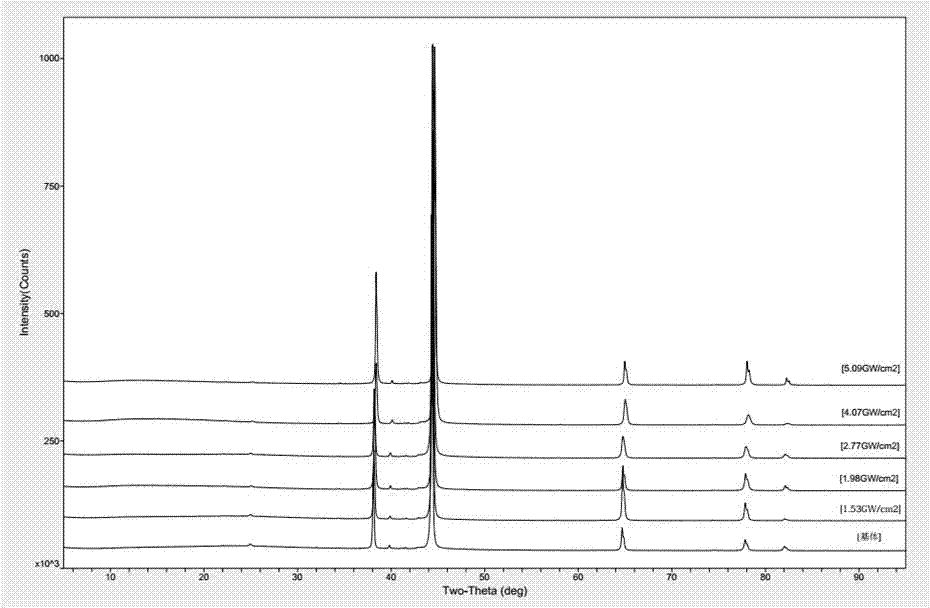

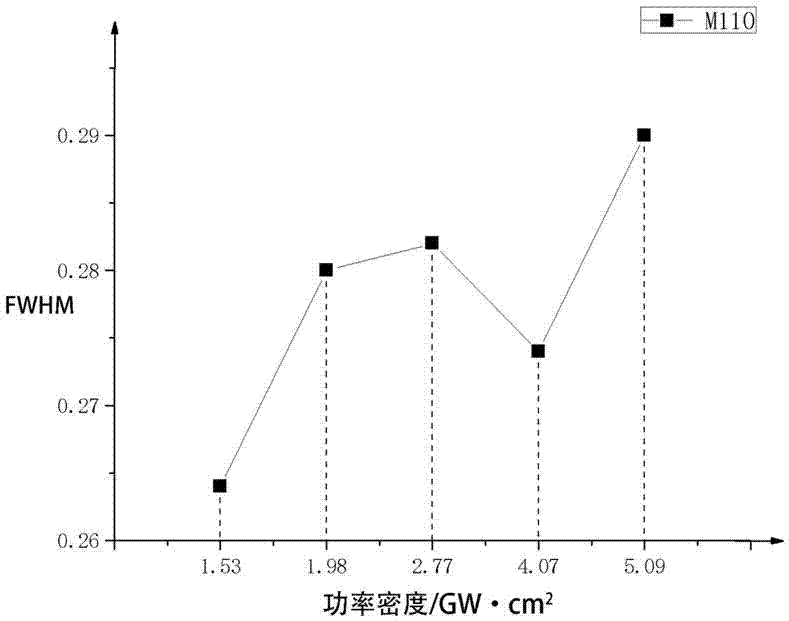

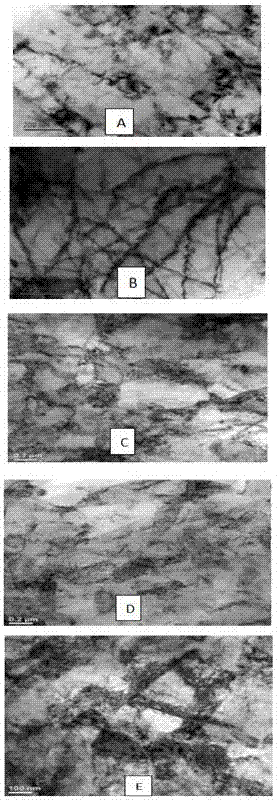

[0037] For several 690 high-strength steel samples, the power density is 1.53 GW / cm 2 , 1.98 GW / cm 2 , 2.77 GW / cm 2 , 4.07 GW / cm 2 , 5.09 GW / cm 2 Perform laser shock peening process.

[0038] Perform surface treatment on the 690 high-strength steel samples after laser shock strengthening; the surface treatment specifically includes the following steps: a. Use pure ethanol or acetone cleaning agent to soak and clean the samples, and the soaking and cleaning time is 3-10 minutes; b. After soaking and cleaning Ultrasonic cleaning is performed on the sample, and the ultrasonic cleaning time is 1-5min to ensure that there is no residual impurity on the surface of the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com