Automatic Detection Method of Cellular Carrier Defect

A technology of automatic detection and honeycomb carrier, which is applied in the direction of optical testing flaws/defects, measuring devices, instruments, etc. It can solve the problems of hole density, mesh number cannot be accurately calculated, large and medium-sized carriers cannot be detected, and the level of device automation is not high, etc., to achieve Large size range, easy promotion and application, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

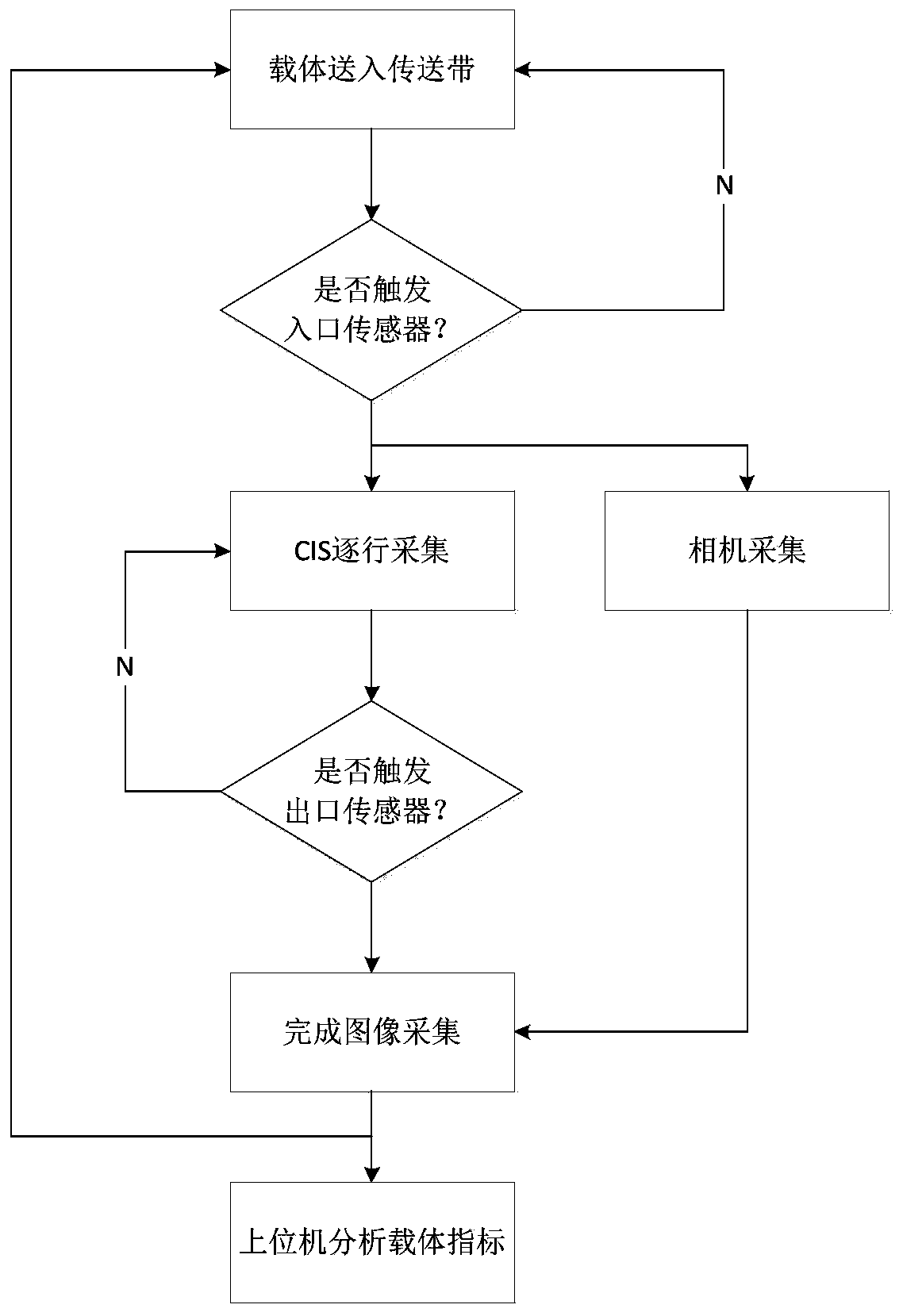

[0058] combine figure 1 , to describe the present invention in detail, but not to limit the claims of the present invention in any way.

[0059] like figure 1 Shown, a kind of honeycomb carrier defective automatic detection method, its concrete steps comprise:

[0060] A. The honeycomb carrier to be tested is sent into the detection area by a belt conveyor with a controllable transmission speed;

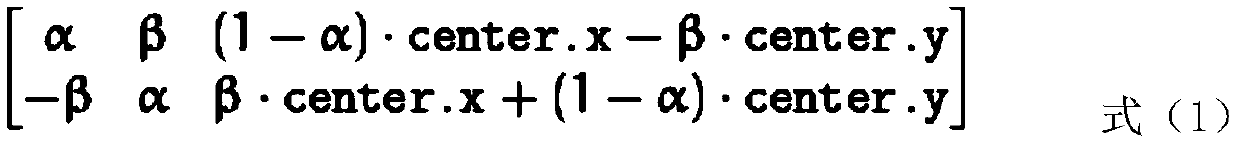

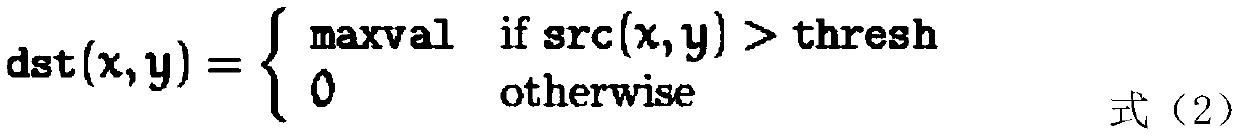

[0061] B. There is a light source in the detection area. Under the projection of the light source, the two end faces of the honeycomb carrier to be tested on both sides of the channel are respectively collected by using a contact image sensor and a high-definition camera. The contact image sensor adopts line by line Image acquisition is carried out by scanning and collecting only one line at a time. The image acquisition frequency of the contact image sensor matches the transmission speed of the conveying device to ensure that the contact image sensor is complete to the end face of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com