Water induction preventing structure and water induction preventing method for crankshaft cavity of high pressure reciprocating pump

A reciprocating pump and water ingress prevention technology, which is applied in the direction of pump components, variable displacement pump components, and components of pumping devices for elastic fluids, etc. It can solve the problems of easy water ingress in the crankshaft cavity, crankshaft stuck, poor lubrication, etc. problems, to achieve the effect of reducing crankshaft stuck faults, prolonging the service life and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

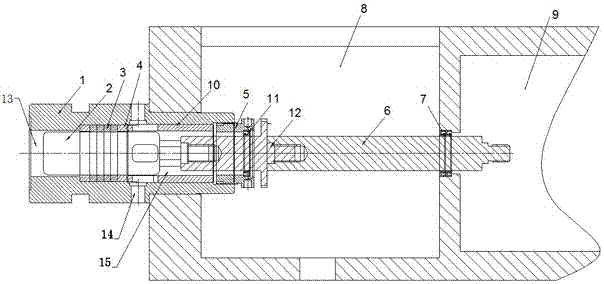

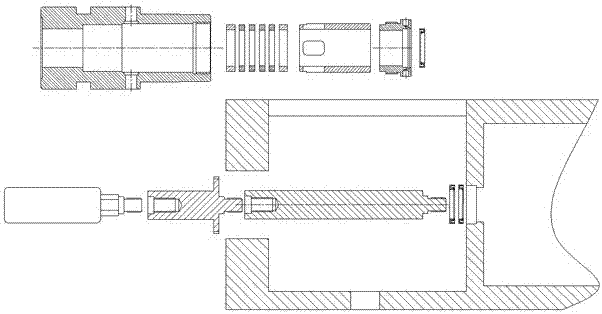

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] Such as Figure 1-2 As shown, a high-pressure reciprocating pump crank chamber anti-water structure includes a pump body with a connecting rod chamber and a crank chamber, the rear of the connecting rod chamber is provided with a mounting hole, and the front of the connecting rod chamber is through a through hole. It communicates with the crankshaft cavity, and a stuffing seal sleeve is arranged in the installation hole, the outer diameter of the front part of the stuffing seal sleeve is smaller than that of the rear part, the front part of the stuffing seal sleeve is arranged in the installation hole, and the rear part of the stuffing seal sleeve Located outside the pump body, a plunger and an extension rod are sequentially arranged in the packing seal sleeve. The front end of the extension rod extends into the connecting rod cavity fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com