Laser direct forming bright powder active adjusting coaxial powder feeding nozzle

A technology of laser direct molding and coaxial powder feeding, applied in the field of additive manufacturing, can solve the problems of low utilization rate of powder, adjustment of spot size, limited applicability, etc., and achieve the effect of strong applicability and stable and reliable mechanism position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

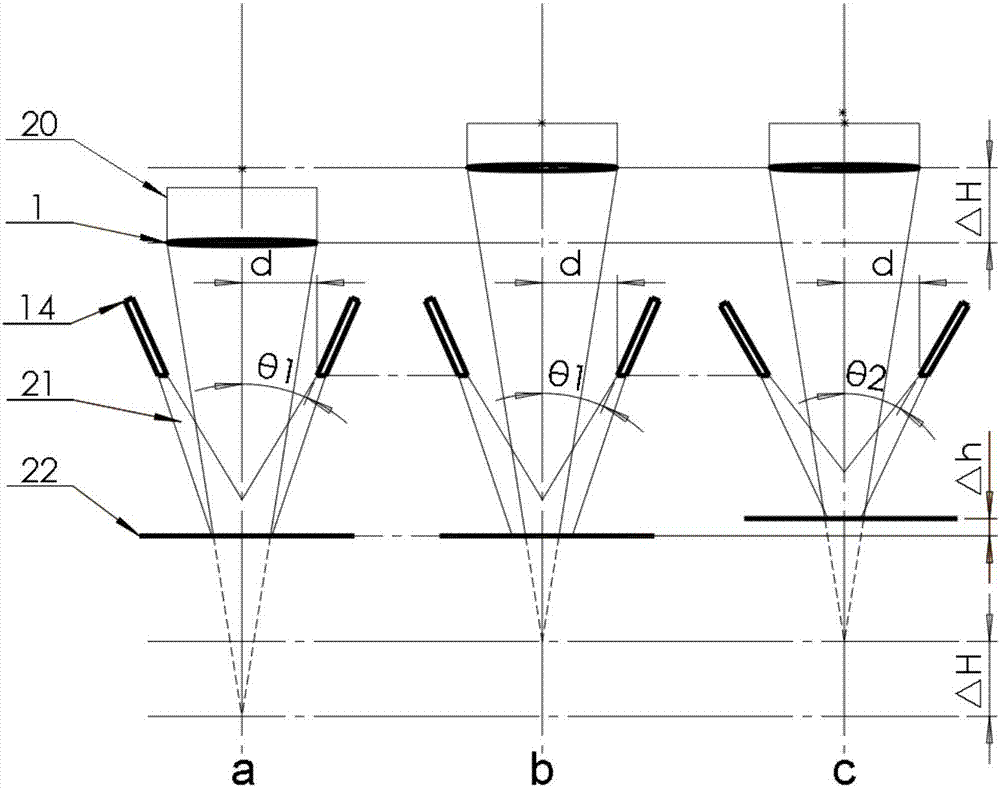

[0039] Specific examples of the present invention are attached figure 1 , 2 As shown, the optical powder active adjustment coaxial powder feeding nozzle for laser direct molding includes: a laser defocus adjustment mechanism, a connecting sleeve 4 and a powder defocus adjustment mechanism; the laser defocus adjustment mechanism is installed inside the connecting sleeve 4 The upper part; the powder defocus adjustment mechanism is installed on the outer middle and lower part of the connecting sleeve 4;

[0040] The inner middle part of the connection sleeve 4 is processed with a mounting platform 401, and the outer central part is processed with an upper ring platform 402 and a lower ring platform 403; the upper ring platform 402 is processed with a through hole, and the lower ring platform 403 is processed with a mounting hole. Hole coaxial processing;

[0041] The laser defocus adjustment mechanism includes: lens 1, mirror base 2, adjusting screw sleeve 3 and protective mirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com