Chemical nickel plating method of aluminum base composite material

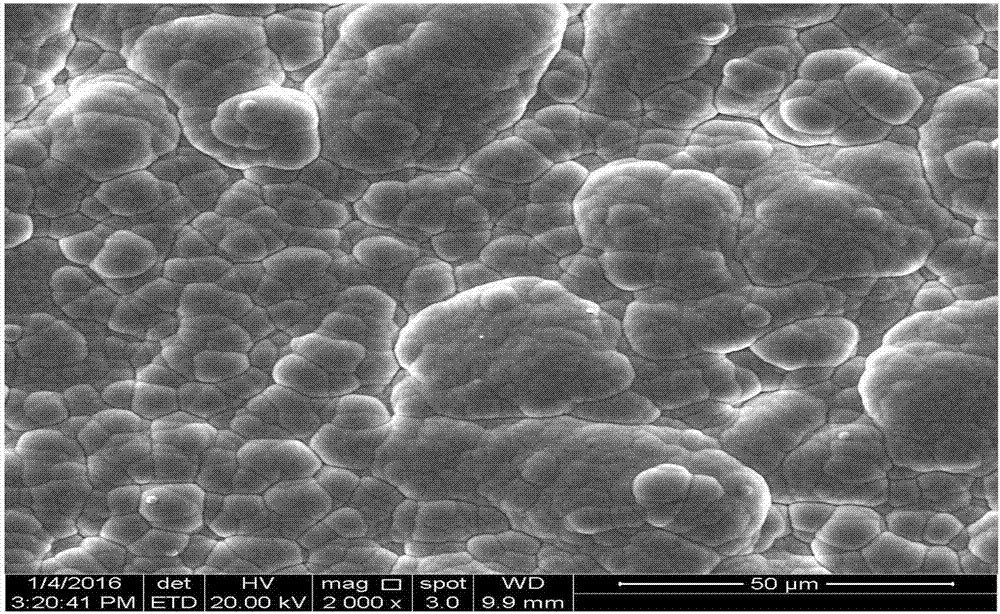

An aluminum-based composite material and electroless nickel plating technology, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of high application cost and narrow application range, and achieve short plating time and high reliability. The effect of strong repeatability and dense internal organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific Embodiment 1: This embodiment is an electroless nickel plating method for aluminum-based composite materials, which is completed according to the following steps; use ammonia water to adjust the pH value of the electroless plating solution to 9-11, and then the aluminum-based composite material When the temperature of the electroless plating solution is 70-90°C, the plating is continued for 40min-120min, and the electroless nickel plating is completed; the solvent of the electroless plating solution is deionized water, and the solute is NiSO 4 ·6H 2 O, NaH 2 PO 2 ·H 2 O, C 6 h 5 Na 3 o 7 2H 2 O and NH 4 Cl, and NiSO in electroless plating solution 4 ·6H 2 The concentration of O is 20g / L~35g / L, NaH 2 PO 2 ·H 2 O concentration is 20g / L~30g / L, C 6 h 5 Na 3 o 7 2H 2 The concentration of O is 25g / L~40g / L, NH 4 The concentration of Cl is 50g / L~60g / L.

[0016] The aluminum-based composite material described in this embodiment is a silicon carbide p...

specific Embodiment approach 2

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the specific process of an electroless nickel plating method for an aluminum-based composite material is as follows: first use acetone to clean and degrease the aluminum-based composite material, and then use deionized water Wash, then pickle or alkali wash, wash again with deionized water, then adjust the pH value of the electroless plating solution to 9~11 with ammonia water, and continue plating for 40min at the temperature of the electroless plating solution at 70°C~90°C ~120min, after the nickel plating is completed, wash it with deionized water and dry it, and the electroless nickel plating for welding aluminum matrix composite materials is completed. Others are the same as the first embodiment.

[0019] In order to ensure the amount of electroless nickel plating, the surface of the part to be plated that is in contact with the immersion plating solution must be the base material itself,...

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that when the aluminum-based composite material is silicon carbide particle-reinforced aluminum-based composite material, sulfuric acid with a mass fraction of 15% to 25% is used for acidification. Washing, pickling time is 3min ~ 10min. Others are the same as those in Embodiment 1 or 2.

[0022] The silicon carbide particle-reinforced aluminum-based composite material in this embodiment is 55%-65% SiCp / A356 or 55%-65% SiCp / 6061.

[0023] Pickling is to immerse the metal workpiece in an acid solution to remove the oxide film of the metal. In order to have a better combination between the electroless nickel plating substrate and the nickel layer, sulfuric acid is generally used. Sulfuric acid has a strong ability to dissolve metal substrates, and has a better exfoliation effect on removing oxide scales, and the acid mist is small. Its concentration is controlled at 15% to 25%, the most suitab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com