Fabric processing mechanism

A processing mechanism and fabric technology, which is applied in textile processing machine accessories, textile material processing, textile material carrier, etc., can solve the problems of low processing efficiency and long fabric processing cycle, and achieve the goal of improving processing efficiency and shortening processing cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

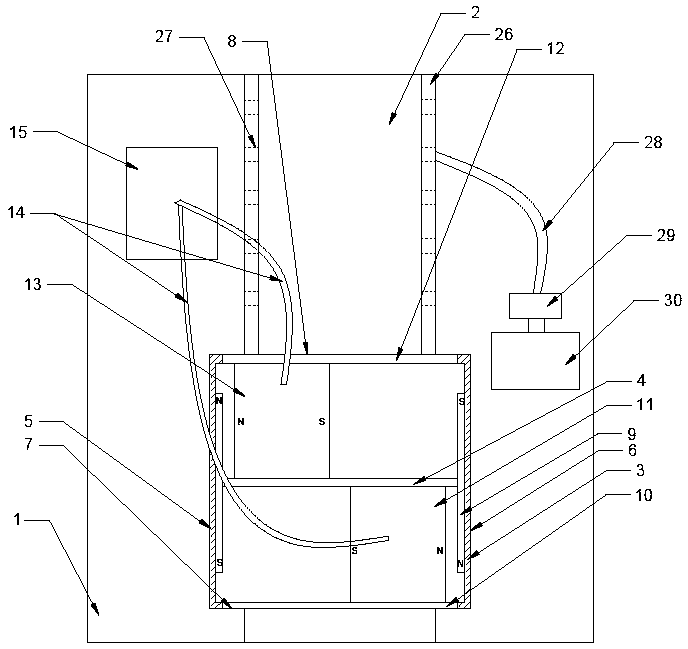

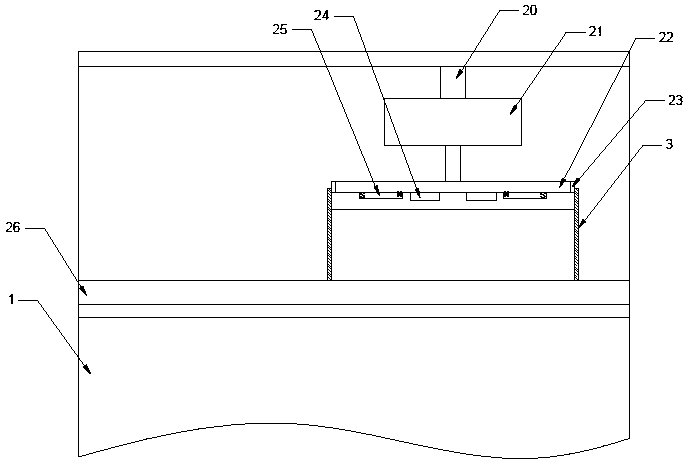

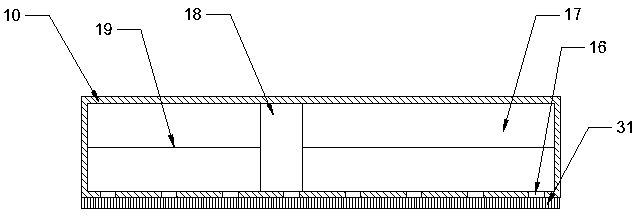

[0019] The reference signs in the accompanying drawings include: frame 1, conveyor belt 2, cube 3, partition plate 4, left side wall 5, right side wall 6, front side wall 7, rear side wall 8, driving magnet 9, the first One slide rail 10, first magnet 11, second slide rail 12, second magnet 13, conveying pipe 14, paint box 15, leakage hole 16, chute 17, collection box 18, spring 19, support rod 20, motor 21. Rotary arm 22, trigger switch 23, heating resistor 24, electromagnet 25, limit plate 26, recovery hole 27, recovery pipe 28, suction pump 29, recovery box 30, brush layer 31.

[0020] The embodiment is basically as attached figure 1 , figure 2 Shown: the processing mechanism of cloth, comprises frame 1, is installed on the frame 1 and is used for the conveyer belt 2 of cloth, and the both sides of conveyer belt 2 is respectively installed limit plate 26, and the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com