Long-service-life waste heat recovery apparatus for coke oven waste flue gas

A technology of waste heat recovery device and coke oven flue, which is applied in the heating of coke oven, discharge device of dry distillation gas, coke oven, etc., which can solve the problems of blockage of heat transfer oil channel, medium corrosion, low heat exchange efficiency, etc., and achieve reduction The effect of temperature change speed, extended service life, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

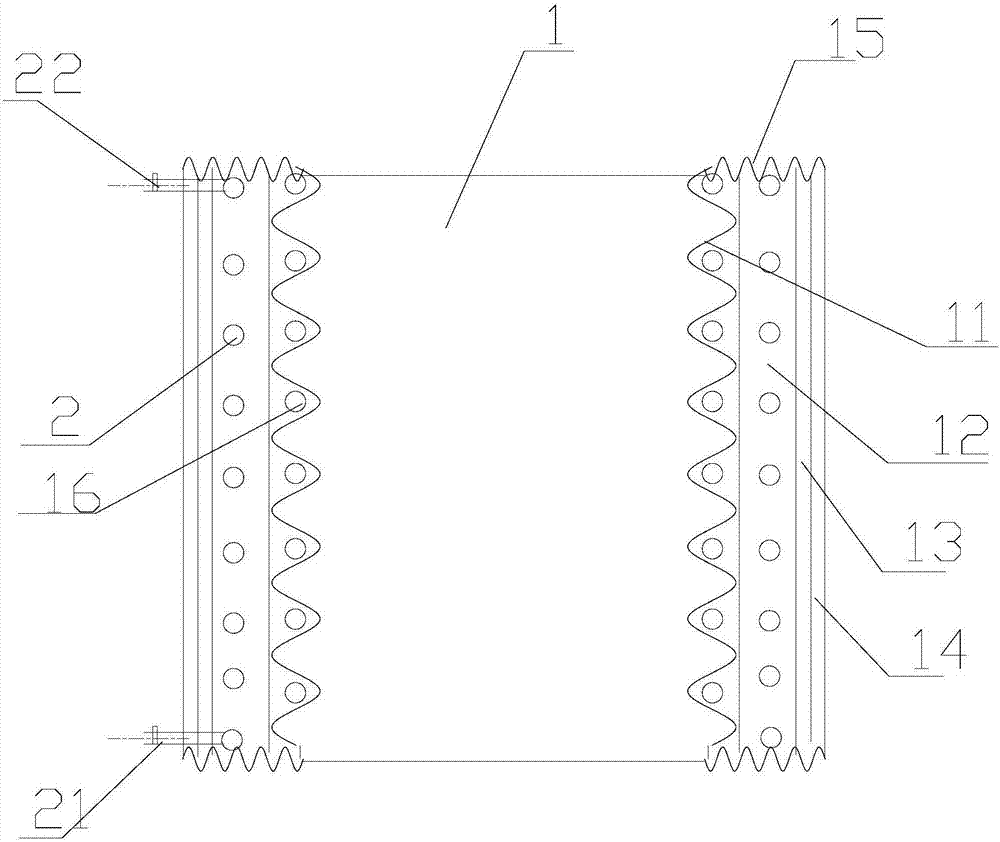

[0019] A coke oven flue waste heat recovery device with long service life, comprising a flue gas pipe (1) and a heat exchange coil (2); the flue gas pipe (1) includes a corrugated disc (15), a spiral heating pipe (16) And the inner cylinder wall (11), the phase change material layer (12), the heat insulation layer (13), and the outer cylinder wall (14) arranged sequentially from the inside to the outside; the inner cylinder wall (11) is a bellows; the The inner cylinder wall (11), the top and the bottom of the outer cylinder wall (14) are respectively connected by corrugated discs (15) welding; the spiral heating pipe (16) is arranged on the inner cylinder wall (11), corresponding Between the change material layers (12); the heat exchange coil (2) is arranged in the phase change material layer (12), with a medium inlet (21) at the bottom and a medium outlet (22) at the top.

[0020] The inner cylinder wall (11) is made of high-efficiency heat-conducting composite material, and...

Embodiment 2

[0022] It is basically the same as Example 1, except that the thermally conductive composite material is made of at least the following components by weight: 100 parts of iron, 12.2 parts of chromium, 5.12 parts of nickel, 0.86 parts of silicon, 0.64 parts of carbon, manganese 0.70 parts, 0.5 parts of titanium nitride, 1.4 parts of carbon nanotubes, 1.6 parts of nano copper, 0.8 parts of nano zinc, 3.2 parts of chitosan.

Embodiment 3

[0024] It is basically the same as Example 1, except that the thermally conductive composite material is made of at least the following components by weight: 100 parts of iron, 12.4 parts of chromium, 5.14 parts of nickel, 0.88 parts of silicon, 0.66 parts of carbon, manganese 0.68 parts, 0.7 parts of titanium nitride, 1.6 parts of carbon nanotubes, 1.4 parts of nano-copper, 1.2 parts of nano-zinc, and 2.8 parts of chitosan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com