Large blade type workpiece robot collaborative grinding system and method

A robot and blade technology, applied in the direction of grinding workpiece support, workpiece feed motion control, grinding machine, etc., can solve the problem of the robot automatic grinding system for the surface of wind power blades that has not been perfected, the processing variability of blade parts, and the large size range, etc. problems, to achieve the effect of improving product processing efficiency, ensuring processing quality and consistency, and stable processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with specific drawings and embodiments.

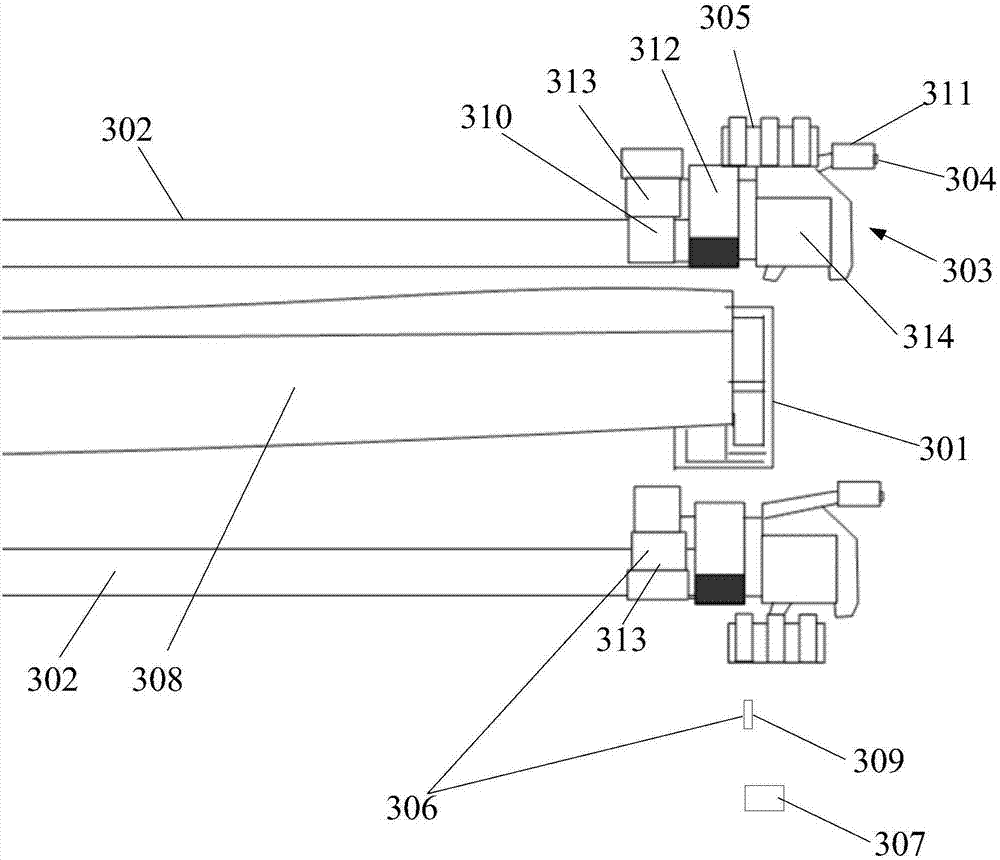

[0045] Such as figure 1 with figure 2 As shown, a robot collaborative grinding system for large-scale blade workpieces proposed by the present invention includes: a blade flip clamping module 301, a horizontal guide rail 302, N robot grinding units 303, and N measuring modules corresponding to the robot grinding units 304, the control module 306 and the upper computer module 307; wherein N is a positive integer; it should be noted that the specific number of robot grinding units 303 can be flexibly increased or decreased according to the length of the blade 308 and the required grinding efficiency; each robot grinding unit 303 is equipped with a measurement module 304;

[0046] The control module 306 includes a tooling control submodule 309 and N robot grinding unit control submodules 313;

[0047] The blade 308 to be polished is installed on the blade turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com