Automatic feeding and taking device for downlight spring

A technology of reclaiming device and feeding device, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost, inconvenience, laborious and laborious manual operation, etc., and achieve the effect of simplifying structure, reducing cost and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

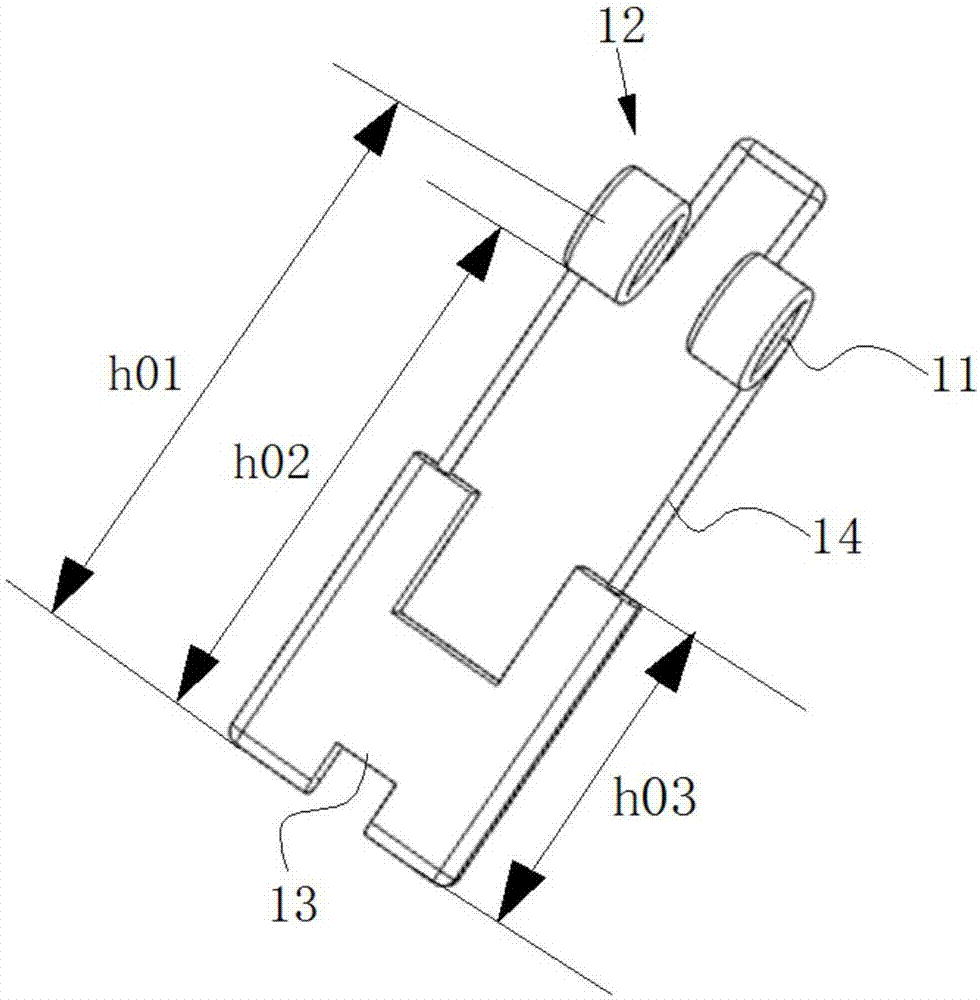

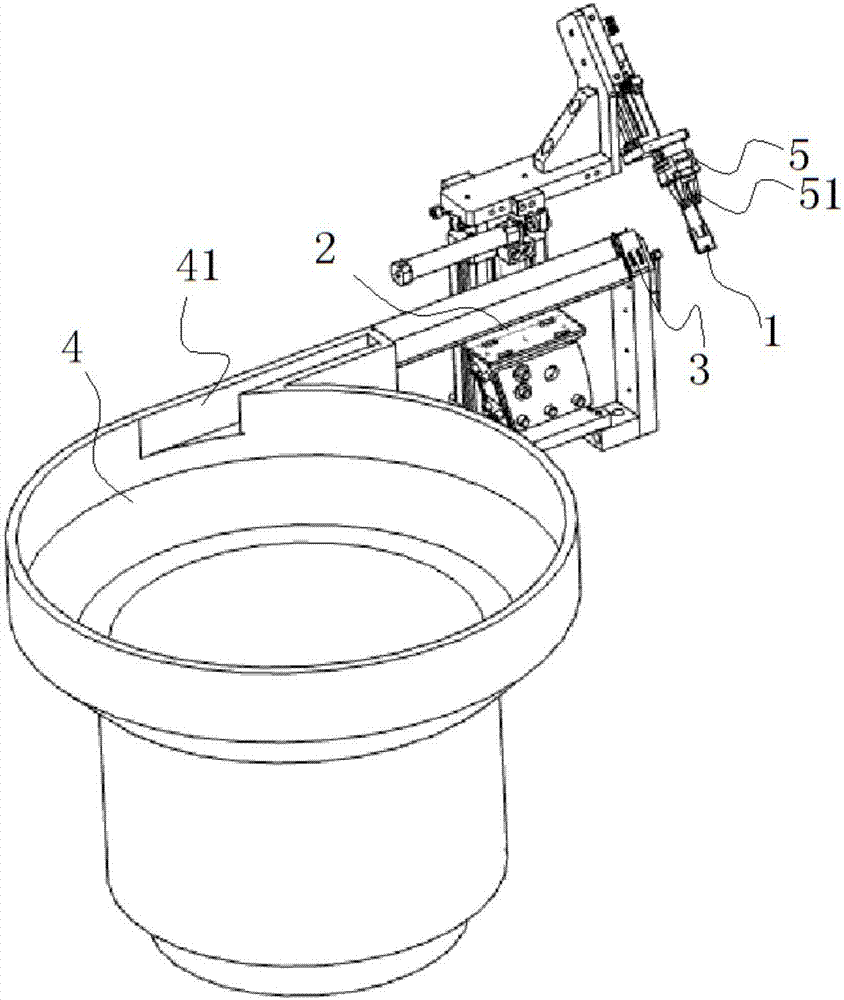

[0050] Example 1: A downlight spring automatic feeding and retrieving device, such as Figure 1 to Figure 3-3 with Figure 5 to Figure 10 As shown, spring 1 is provided with one end of coil 11 as head end 12, and the other end as tail end 13, with the conveying direction of spring as the front, including feeding device and retrieving device, and described feeding device includes feeding mechanism 2 and spring in place Mechanism 3, the material taking device includes a clamping mechanism 5, the spring in place mechanism is located in front of the feeding mechanism, and the clamping mechanism is located in front of the taking mechanism;

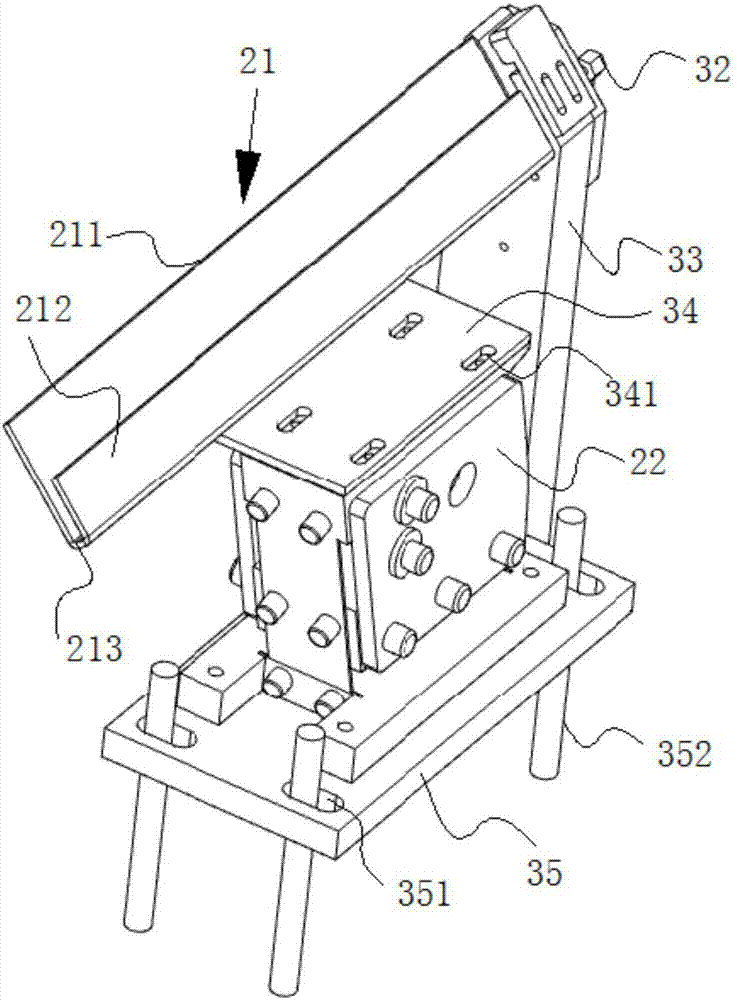

[0051] The feeding mechanism 2 includes a feeding chute 21 and a direct vibration auxiliary feeder 22 installed below the feeding chute, and the discharge end of the feeding chute is docked with the spring in place mechanism;

[0052] The feeding chute 21 includes a first feeding plate 211, a second feeding plate 212 and a bottom plate 213, th...

Embodiment 2

[0088] Embodiment 2: Similar in structure to Embodiment 1, the difference is: as Figure 4-1 to 4-3 as shown,

[0089] The structure of the feeding trough is: the height h22 of the second feeding plate is greater than the height h02 of the bottom surface of the spring to the lower tangent of the coil of the spring. When feeding, the lower edge of the coil of the spring hangs on the first The upper ends of the two feeding plates and the tail ends of the springs are not in contact with the bottom plate.

[0090] Preferably, the height h22 of the second feeding plate is 1-2 mm larger than the height h02 from the bottom surface of the spring to the lower tangent of the coil of the spring.

[0091] Preferably, the downlight spring generally has three specifications, and the height of the second feeding plate is greater than the height from the bottom surface of the spring of the largest specification to the lower tangent of the coil, because the spring hangs on the lower edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com