Argon arc welding torch with cooling function and device with the same

An argon arc welding torch and functional technology, applied in the field of welding devices and argon arc welding torches, can solve the problems that the arc energy density cannot be further improved, the service life of the insulating material is adversely affected, and the adaptability of the welding material is affected, so as to improve the arc penetration, The effect of improving the efficiency of welding operation and improving the quality of welding seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

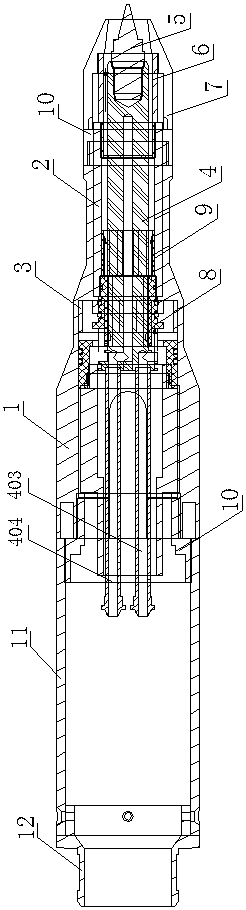

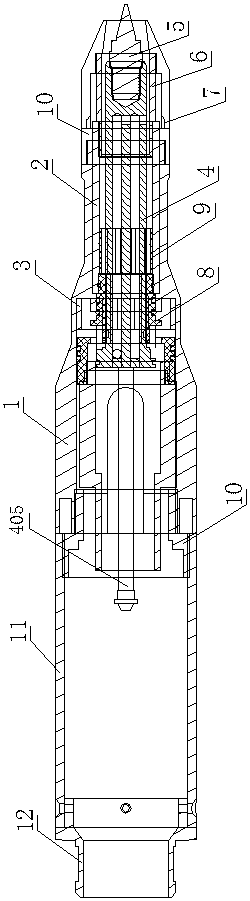

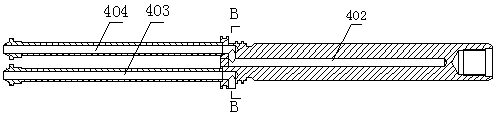

[0025] like Figure 1 to Figure 9 The shown argon arc welding gun and welding device with cooling function include a gun body shell 1, an insulator 2 connected to the first end of the axial inner hole of the gun body shell 1, and the middle part of the axial inner hole of the gun body shell 1 is connected. The first support ring 3, the sealing body 8 connected with the axial inner hole of the gun shell 1, the electrode connecting body 4 connected with the insulator 2, the first supporting ring 3 and the axial inner hole of the sealing body 8, and the electrode connecting body 4 The electrode 5 connected to the first end of the connecting body 4, the eddy current ring 10 connected to the outer side of the first end of the gun shell 1, the porcelain nozzle 6 connected to the axial inner hole of the insulator 2, and the near electrode 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com