Manufacturing method for dental implant assembly

A manufacturing method and technology for dental implants, applied in dental implants, dentistry, and prosthetics, etc., can solve problems such as high technical difficulty, increased medical expenses, and painful surgery for patients, and achieve convenient and accurate information collection, strong data processing capabilities, The effect of safe, stable and reliable information transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

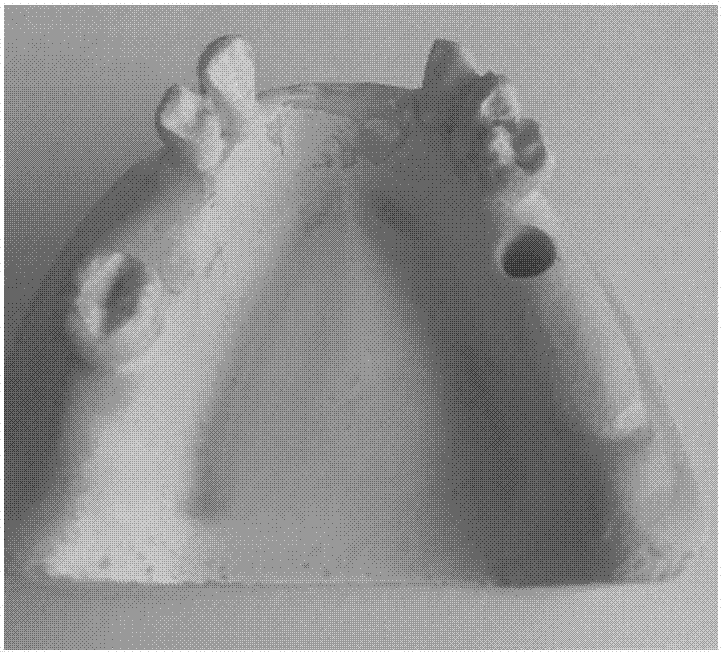

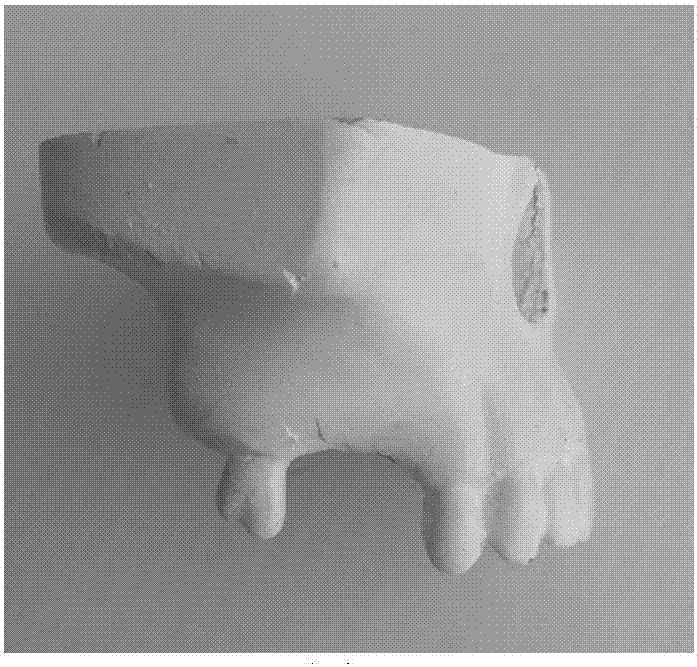

[0042] The technical problem to be solved by the present invention is: the conditions of the jaws of many patients (such as bone height, width, density, etc.) are not very ideal, and it is often necessary to perform bone augmentation bone grafting in clinical operations, and even adapt to implantation by changing the surgical method. The implantation of body, brings huge operation pain to patient like this, also increased medical expenses simultaneously. The technical idea proposed by the present invention for this technical problem is: obtain the patient's oral cavity data based on CBCT, establish the patient's jawbone digital model according to the oral cavity data, and then print out the jawbone entity model based on the jawbone digital model and 3D printing technology ;According to the patient's tooth loss situation and the digital model of the jaw, the digital model of the implant, the digital model of the implant fixture and the guide plate model for the implant are desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com