Shrimp sheller

A technology for peeling shrimp and a peeler, applied in the field of kitchen tools, can solve problems such as increased labor costs, sore hand muscles, physical discomfort, etc., and achieve the effects of reducing potential safety hazards, foldable volume, and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

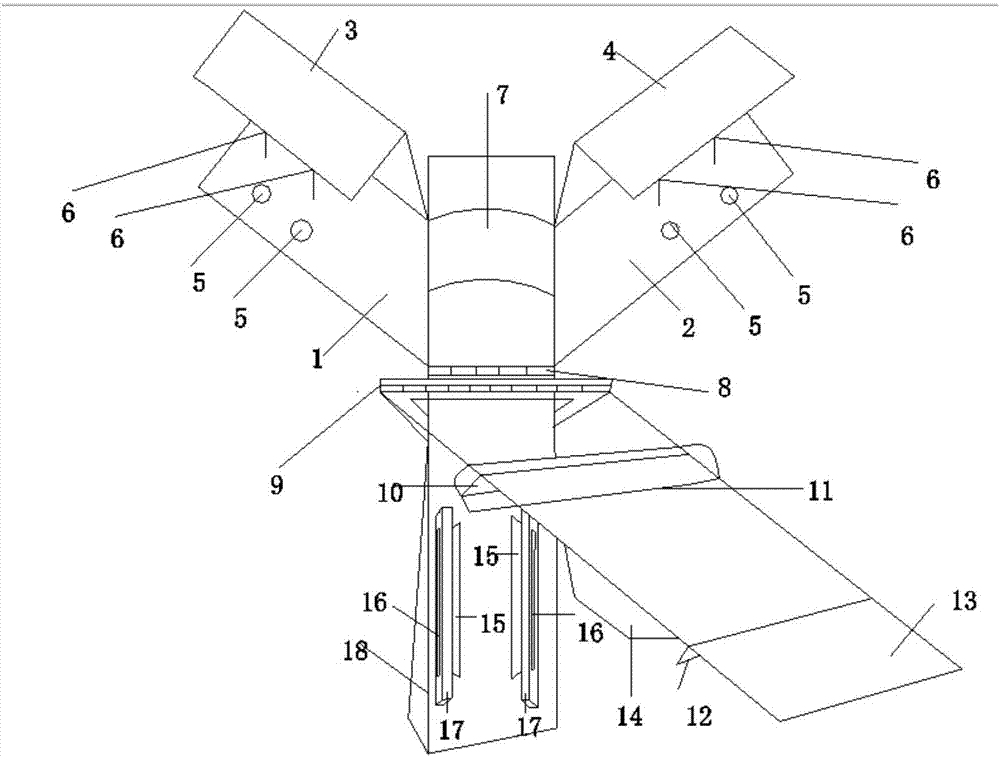

[0012] A kind of shrimp peeling device as shown in the figure, comprises shrimp head fixer, shrimp clamp fixer and shrimp body stripper, shrimp body stripper comprises base plate 18, turnover plate 13, support 9, the cube strip 17 on base plate 18 surface There is a pressing blade 15 on the upper blade 13, an upper blade 10, a lower blade 12, a shrimp body pressure plate 14 that can slide up and down, and a steel wire 11 that can slide up and down just below the upper blade 10, and the bottom plate 18 is from top to bottom. It gradually rises, the bracket 9 is fixed on the base plate 18, the flap 13 is a movable link with the bracket 9, the flap can rotate 180 degrees around the movable link, the bottom plate 18 and the shrimp head holder are a movable link 8, the bottom plate 18 and the shrimp head fixer can be folded.

[0013] The surface of the shrimp head holder has a shrimp headband 7, and the shrimp headband 7 is materials such as elastic ceramic fiber cloth, rubber.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com