Antifouling anti-scale nano easy-to-clean coating solution, and preparation method and application thereof

An easy-to-clean, coating solution technology, applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems that cannot be used indoors for a long time, can not be used outdoors for a long time, and achieve good Hydrophobic and oleophobic properties, mild conditions, easy to keep clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

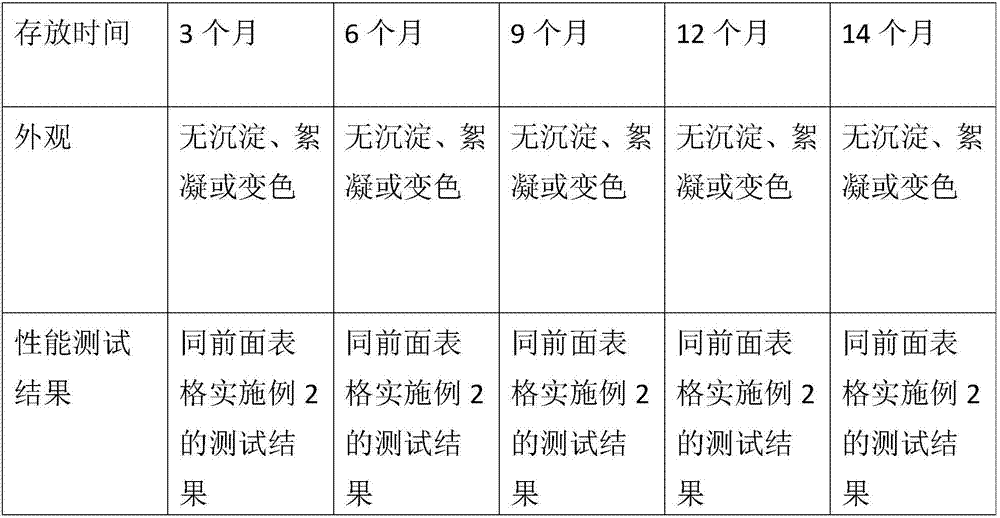

Examples

Embodiment 1

[0034] Dissolve 20g of TEOS (tetraethyl tetrasilicate) in 80g of absolute ethanol, add nitric acid to adjust the pH to 2, stir at 45°C for 24 hours to obtain a stable sol solution, add 2g of hydroxyl-modified perfluoropolyether and 0.1ml of lauric acid Butyltin, stirred for 24H. Add 0.5g of gas-phase nano-silica, and disperse for 1H under high-speed shearing to obtain an anti-fouling nano-scale easy-to-clean coating solution. Spray the coating solution on the surface of household ceramics and glass with a pressure spray gun to make it level naturally, and test it after 24 hours.

Embodiment 2

[0036] Dissolve 20g of TEOS in 80g of absolute ethanol, add nitric acid to adjust the pH to 2, stir at 45°C for 24H to obtain a stable sol solution, add 2g of hydroxyl-modified fluorine-containing acrylic resin and 0.1ml of butyltin laurate, and stir for 24H. Add 0.5g of gas-phase nano-silica, and disperse for 1H under high-speed shearing to obtain an anti-fouling nano-scale easy-to-clean coating solution. Spray the coating solution on the surface of household ceramics and glass with a pressure spray gun to make it level naturally, and test it after 24 hours.

Embodiment 3

[0038] Dissolve 20g of tetrabutyl titanate in 80g of isopropanol, add 10% acetic acid until the pH is 4, the speed of adding acetic acid must be controlled to be very slow, and it takes at least 4 hours to complete the dropwise addition. , to obtain a stable sol solution, add 2g of hydroxyl-modified perfluoropolyether and 0.1ml of butyltin laurate, and stir for 24H. Add 0.5g of gas-phase nano-silica, and disperse for 1H under high-speed shearing to obtain an anti-fouling nano-scale easy-to-clean coating solution. Spray the coating solution on the surface of household ceramics and glass with a pressure spray gun to make it level naturally, and test it after 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com