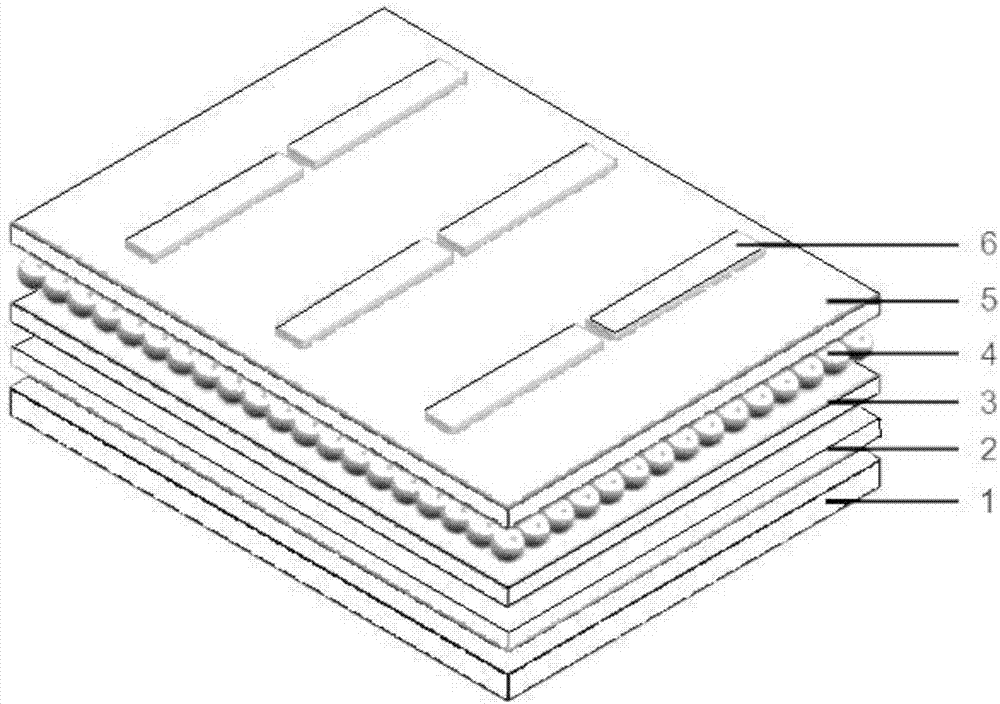

NiO composite film, quantum dot light-emitting device and the preparation and application of the same

A technology of quantum dot light emitting and composite material thin film, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of short life of quantum dot light emitting devices, improve performance and stability, improve hole injection ability, accelerate The effect of migration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In the present embodiment, a kind of preparation method of Cu:NiO / NiO composite film comprises the following steps:

[0034] a. Mix 0.97mmol of nickel acetate tetrahydrate and 0.03mmol of copper acetate monohydrate and dissolve them in 10ml of absolute ethanol, add 60.4μl of ethanolamine dropwise while stirring as a stabilizer, stir at 70°C for 4h, and then Stir at room temperature for 8h to obtain Cu:NiO solution for subsequent use;

[0035] b. Dissolve 1 mmol of nickel acetate tetrahydrate in 10 ml of absolute ethanol, add dropwise 60.4 μl of ethanolamine as a stabilizer while stirring, stir at 70°C for 4 hours, and then stir at room temperature for 8 hours to obtain a NiO solution for later use;

[0036] c. draw the Cu:NiO solution prepared in the step a of 120 μl on the ITO substrate with a pipette gun, spin-coat 50s with a speed of 4000rpm, prepare Cu:NiO coating liquid film on the ITO substrate, The Cu:NiO coating liquid film was dried and solidified at 400°C in ...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, especially in that:

[0041] In the present embodiment, a kind of preparation method of Li:NiO / NiO composite film comprises the following steps:

[0042] a. Mix 0.97mmol of nickel acetate tetrahydrate and 0.03mmol of lithium chloride and dissolve in 10ml of absolute ethanol, add dropwise 60.4μl of ethanolamine as a stabilizer while stirring, stir at 70°C for 4h, then at room temperature Stir 8h, obtain Li:NiO solution, standby;

[0043] b. This step is the same as in Embodiment 1;

[0044] c. draw the Li:NiO solution prepared in the step a of 120 μl on the ITO substrate with a pipette gun, spin-coat 50s with a speed of 4000rpm, prepare Li:NiO coating liquid film on the ITO substrate, Dry and solidify the Li:NiO coated liquid film in air at 400°C, and then perform an annealing treatment for 20 minutes to obtain a Li:NiO cured film. After the Li:NiO cured film is cooled to room temperature, O 3 -Plasma treatment fo...

Embodiment 3

[0048] This embodiment is basically the same as the previous embodiment, and the special features are:

[0049] In the present embodiment, a kind of preparation method of Mg:NiO / NiO composite thin film comprises the following steps:

[0050] a. Mix 0.97mmol of nickel acetate tetrahydrate and 0.03mmol of magnesium acetate tetrahydrate and dissolve in 10ml of absolute ethanol, add dropwise 60.4μl of ethanolamine as a stabilizer while stirring, stir at 70°C for 4h, and then Stir at room temperature for 8h to obtain Mg:NiO solution for subsequent use;

[0051] b. This step is the same as in Embodiment 1;

[0052] c. draw the Mg:NiO solution prepared in the step a of 120 μl on the ITO substrate with a pipette gun, spin-coat 60s with a speed of 4000rpm, prepare Mg:NiO coating liquid film on the ITO substrate, The Mg:NiO coating liquid film was dried and solidified at 400°C in air, and then annealed for 20 minutes to obtain a Mg:NiO cured film. After the Mg:NiO cured film was coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com