Current transformer with nanocrystalline alloy double magnetic cores

A technology of current transformer and nanocrystalline alloy, applied in the direction of inductor, transformer/inductor shell, magnetic core/yoke, etc., can solve the control circuit error, coercive force, high iron loss per unit of excitation power and complex structure and other problems, to achieve the effect of low excitation power and unit iron loss, high initial permeability, and high saturation magnetic density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

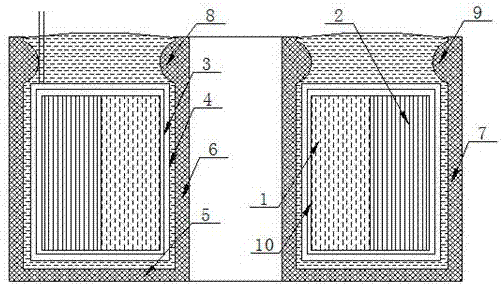

[0017] refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the present invention.

[0018] Such as figure 1 As shown, a nanocrystalline alloy double magnetic core current transformer includes a transformer composite magnetic core, and the transformer composite magnetic core includes a ring-shaped nanocrystalline magnetic core 2 and an amorphous alloy magnetic core 1, and the nanocrystalline The magnetic core 2 is set on the outside of the amorphous alloy magnetic core 1, and the nanocrystalline magnetic core 2 and the amorphous alloy magnetic core 1 are coaxially arranged; the amorphous alloy magnetic core 1 is made of amorphous alloy magnetic The strip is wound, and the amorphous alloy magnetic strip contains the following elements by mass percentage: silicon element 8%-12%, boron element 5%-8%, manganese element 1.0%-1.8%, cobalt element 0.5% ~1.3%, vanadium 1.2%~2.2%, carbon 2.5%~4.0%, and the balance iron.

[0019] Specifically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com