High-saturation flux density composite magnetic powder, magnetic core and preparation methods thereof

A technology of magnetic induction and magnetic powder, which is applied in transformer/inductor parts, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of lack of soft magnetic powder and its magnetic core products, poor performance of magnetic core, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The preparation steps of the composite magnetic powder and the corresponding magnetic core are: sieving powder A and powder B with a particle size of 8-200 μm; annealing according to their respective best soft magnetic properties; uniformly mixing the annealed powder A and powder B , to obtain composite magnetic powder; add a certain amount of binder, lubricant and insulating agent to the composite magnetic powder, after mixing, sequentially undergo pressing treatment, annealing treatment and painting treatment, and finally prepare various magnetic cores, such as magnetic powders of different shapes core, transformer, inductor and motor stator core, etc. After the composite magnetic powder is mixed with binder, lubricant and insulating agent, it is preferable to carry out proper drying. Proper drying ensures that the mixed powder has a certain fluidity, which is more conducive to molding.

[0063] The composite magnetic powder can also use 3D printing to manufacture and...

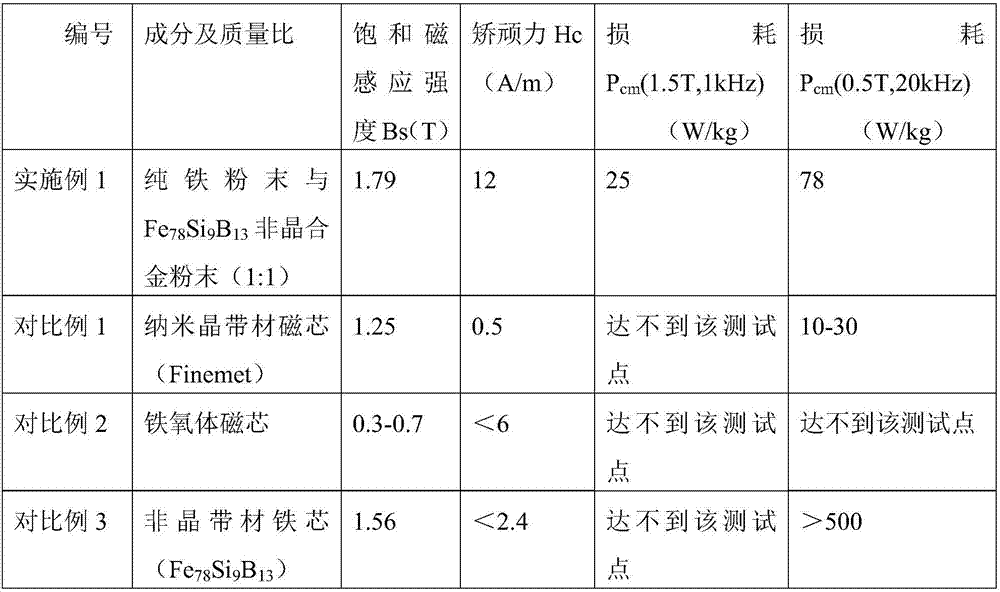

Embodiment 1

[0066] Embodiment 1 pure iron powder and Fe 78 Si 9 B 13 Amorphous alloy powder mixing

[0067] In this embodiment, pure iron powder (as powder A) is prepared by high-energy ball milling method, and Fe powder is prepared by water atomization method. 78 Si 9 B 13 Amorphous alloy (expressed in atomic percent, the same below) powder (as powder B). The two powders were annealed separately, and the annealing system of pure iron powder was 800℃×60min; Fe 78 Si 9 B 13 The annealing system of the alloy powder is 400℃×60min; a vacuum atmosphere is used in the annealing process. After sieving respectively, select pure iron powder with a particle size of 30-50 μm and Fe powder with a particle size of 20-40 μm 78 Si 9 B 13 Alloy powder, and uniformly mixed to prepare composite magnetic powder; according to the mass ratio, pure iron powder and Fe 78 Si 9 B 13 The mixing ratio of alloy powder is 50:50.

[0068] According to the following mass percentages, the composite magnet...

Embodiment 2

[0072] Embodiment 2 iron silicon powder and Fe 73.5 Cu 1 Nb 2 Cr 1 Si 15.5 B 7 Nanocrystalline Powder Mixing

[0073] In this example, high-energy ball milling is used to prepare iron-silicon powder, wherein the mass percentage of Si is 6.5% (as powder A), and Fe is prepared by water atomization. 73.5 Cu 1 Nb 2 Cr 1 Si 15.5 B 7 Nanocrystalline powder (expressed as atomic percent as powder B). The two kinds of powders were annealed respectively, among which, the annealing system of iron-silicon powder was 900℃×60min; the annealing system of nanocrystalline powder was 550℃×60min; hydrogen atmosphere was used in the annealing process. After sieving separately, select iron-silicon powder and nanocrystalline powder with a particle size of 30-50 μm, and mix them uniformly to prepare composite magnetic powder; according to the mass ratio, the mixing ratio of iron-silicon powder and nanocrystalline powder is 90:10.

[0074] The composite magnetic powder, insulating agent C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com